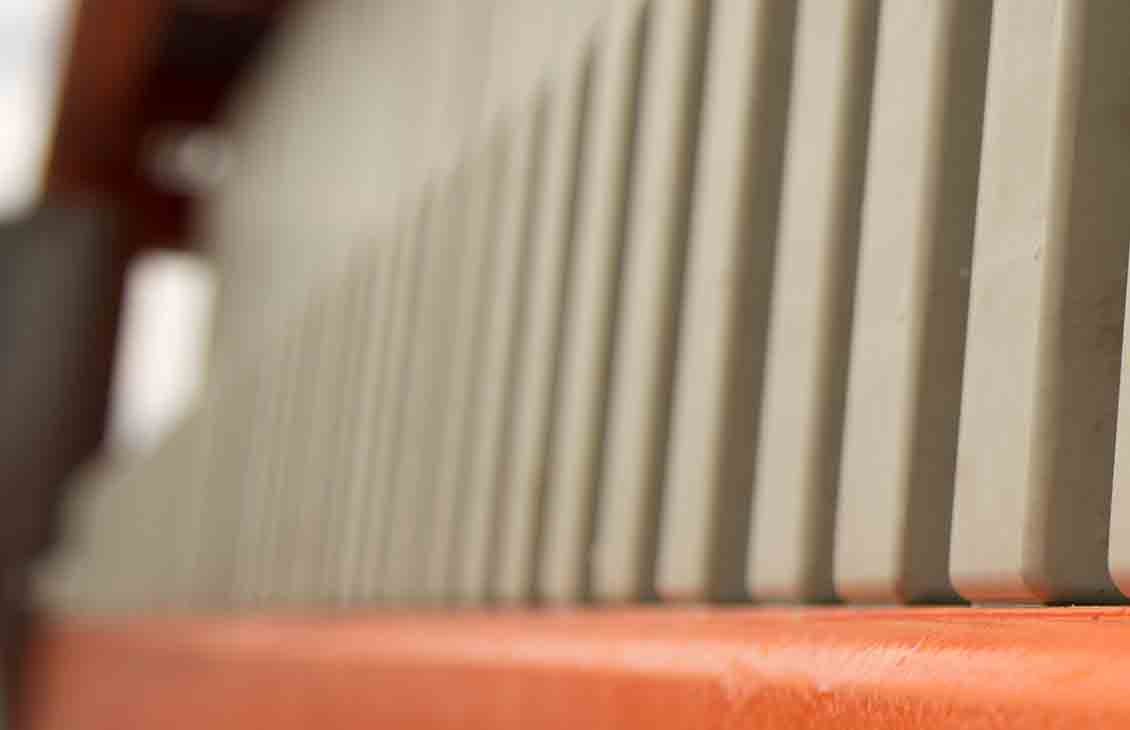

Case Study Extreme-Life Shaker Screens Lasted 4.65 Times Longer Than Conventional Screens

New shaker screens enable an onshore Mexico operator to reduce screen costs by 23% and screen disposal by 77%.

Equipment and services to maintain drilling fluid integrity and minimize waste

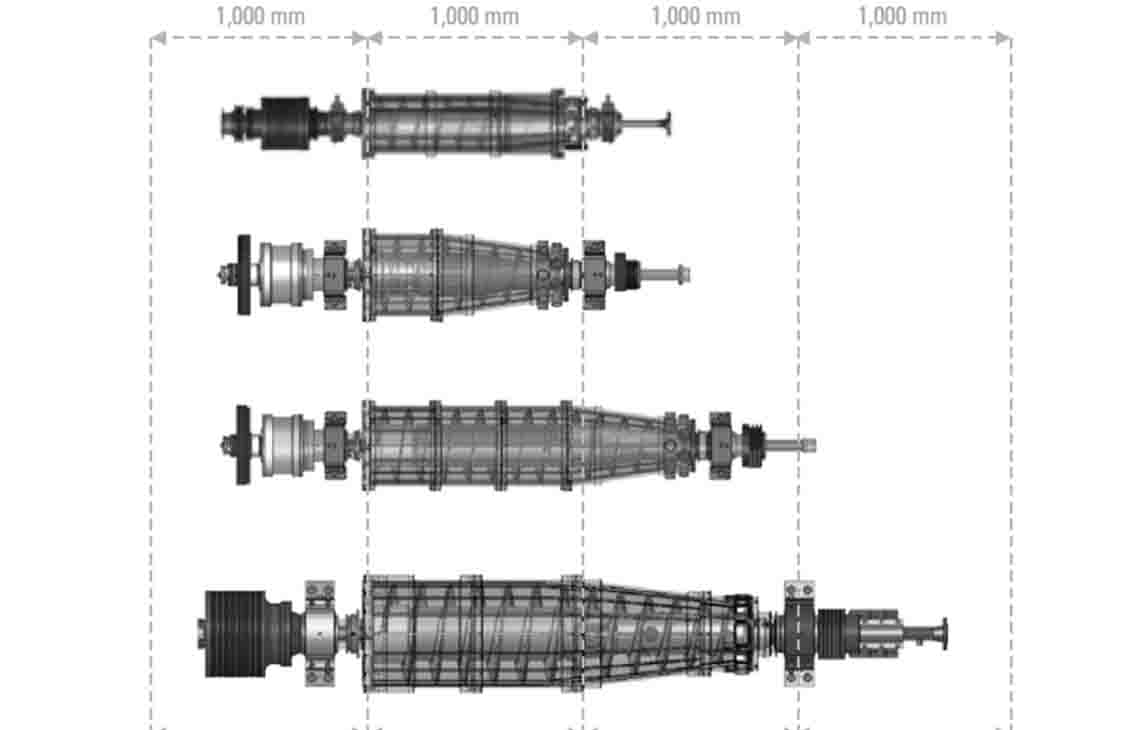

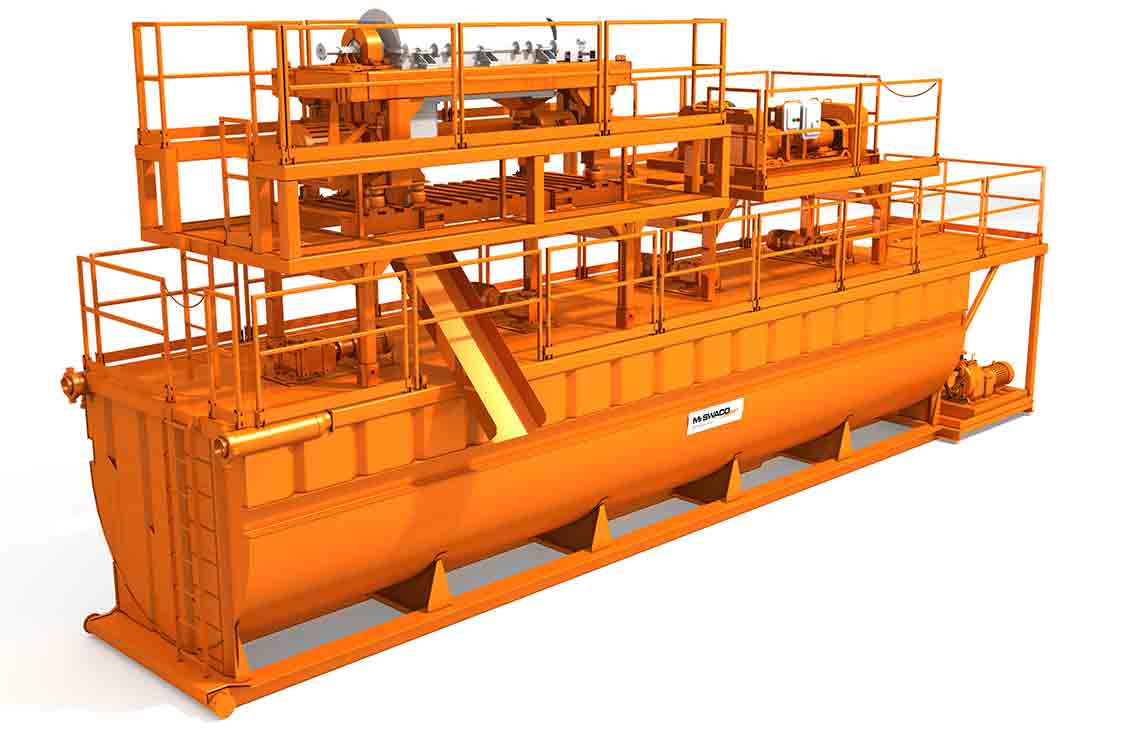

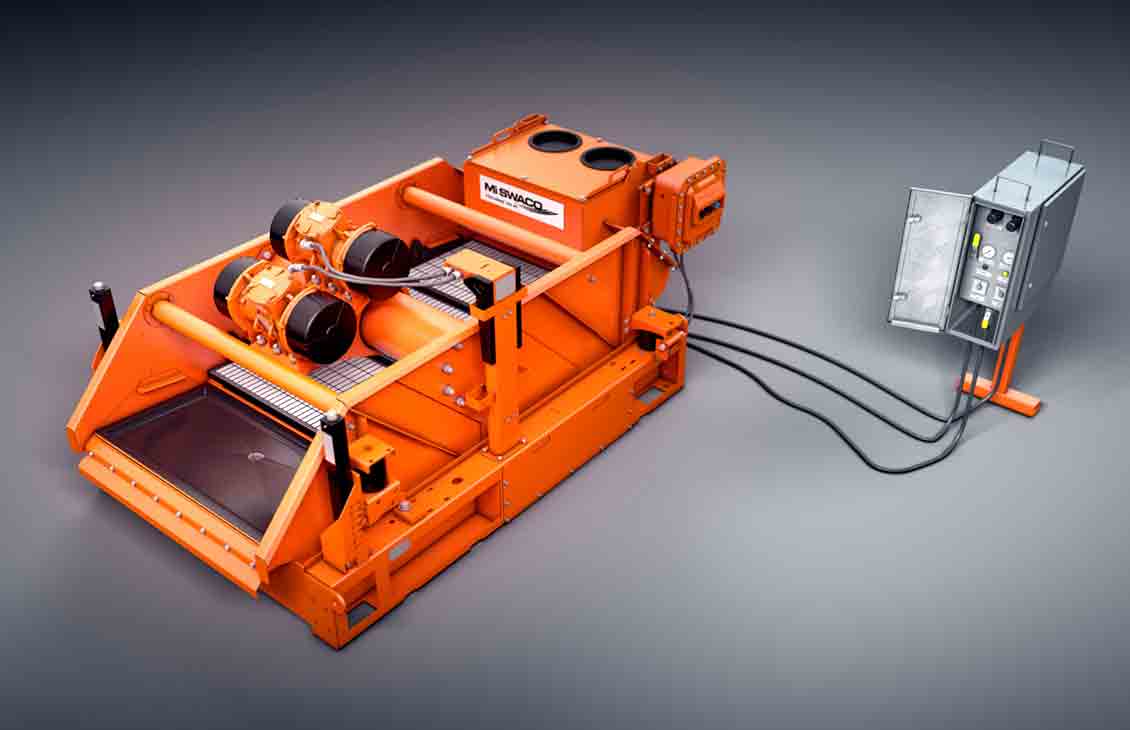

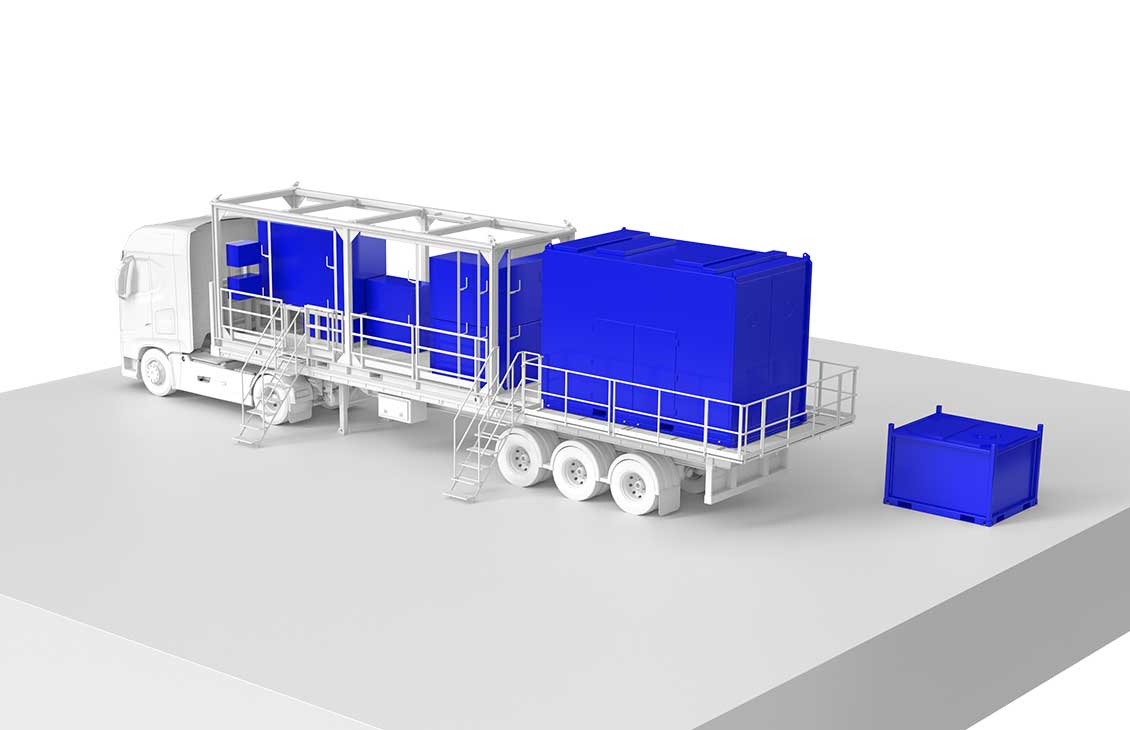

Our solids control technologies optimize drilling efficiencies by maintaining fluid integrity, reducing fluid losses, minimizing HSE impact, and lowering drilling costs through NPT management. Offerings include advanced shale shakers and associated OEM composite screens, new-generation centrifuges and pumps, cuttings dryers, and the RHE-USE two-stage centrifuge system enabling reuse of invert emulsion drilling fluids over multiple wells.

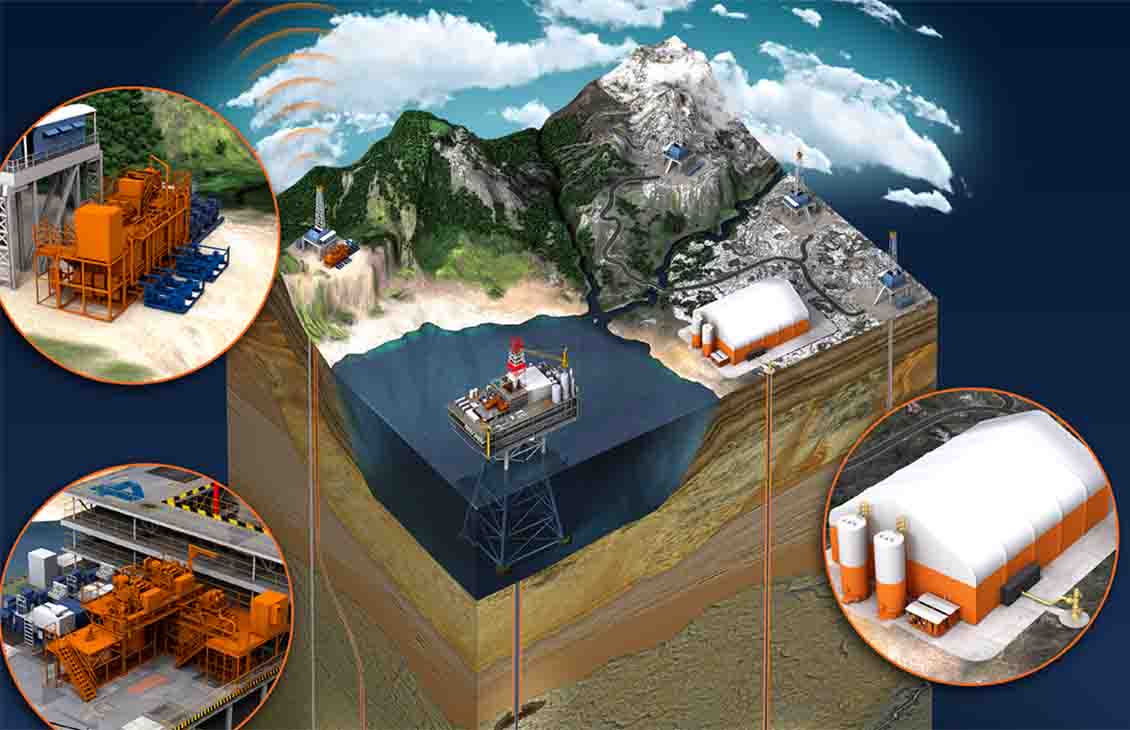

We work closely with rig designers, contractors, operators, and shipyards to customize integrated drilling and waste management configurations for optimal fluid recovery, reduced dilution rates, less waste generation, and lower costs.

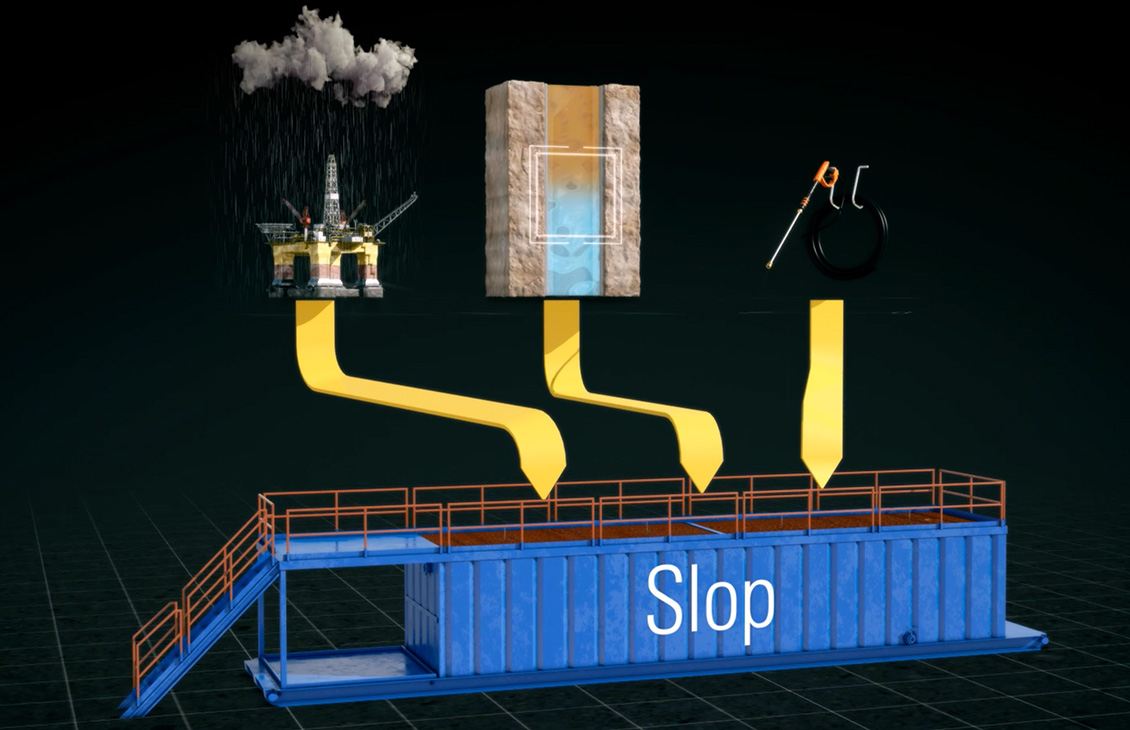

New-generation cuttings management technologies reduce the HSE footprint of drilling operations. They include fully enclosed pneumatic technologies for the containment, handling, temporary storage, and transport of drill cuttings. Thermal and frictional desorption minimize the fluid content of cuttings, significantly reducing total waste volumes and the need for costly transportation. We also have significant expertise in planning, implementing, and monitoring in situ injection of drilling waste. Operators save time, labor, rig space, and mitigate HSE risk by avoiding transportation over water or on roadways.

Screens, plugs, and other shaker equipment are available on The Oilfield Marketplace.

Browse Solids Control

Consistently high-quality solids control performance—on land or offshore. View

Remove dry solids from the entire circulating volume while retaining premium base fluid. View

Reduce costs and waste volumes on shakers from M-I SWACO or third parties. View

Enhance environmental performance. View

Remove low-gravity solids and produce clean fluid for reuse in drilling systems. View

Comply with environmental regulations by safely and efficiently collecting and containing drill cuttings. View

Meet or exceed stringent environmental standards in remote and environmentally sensitive locations. View

Maximizes liquid-solid separation in large-volume processing. View

Combine pulsating technology with ultraefficient screens for the utmost in cuttings treatment and fluid recovery. View

Minimize HSE risks, waste generation, and emissions. View

Reduce offshore drilling waste stream by up to 90%, reduce trips to shore, lower emissions and fuel use. View

Precisely control pressure in coiled tubing, drilling, completions, or any other critical operation. View

Protect your well and completion with optimized filtration solutions. View