Clamp Quick-Connect System

Faster, more reliable high-pressure connection for frac hoses

Replace risky hammer unions for connecting high-pressure frac hoses with faster setup, safer clamp system.

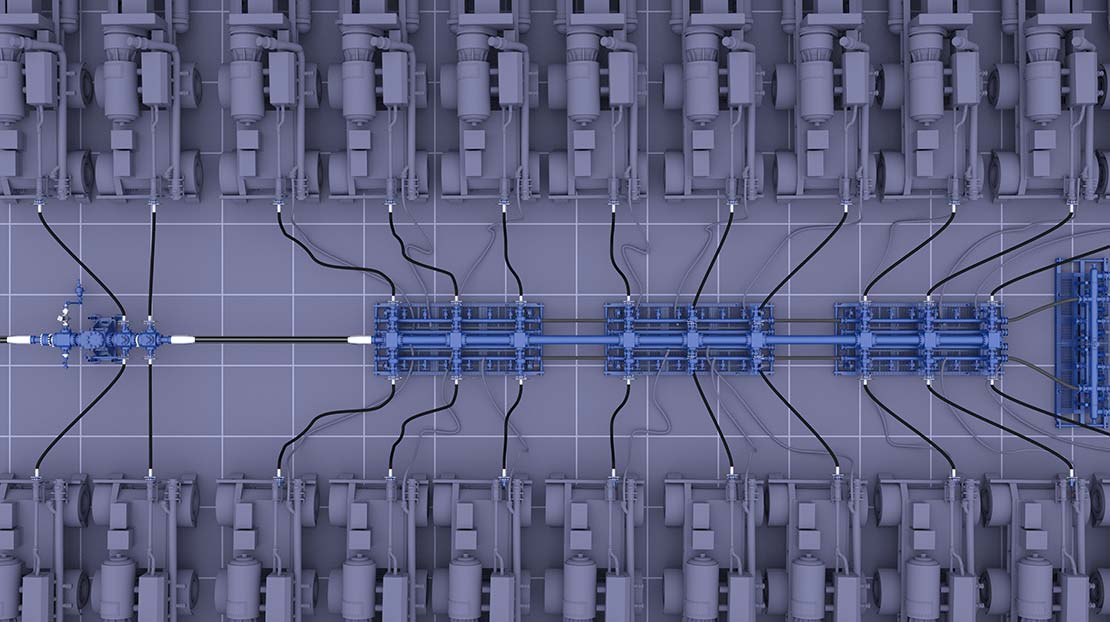

Easily accommodate any pump configuration with greater efficiency and safety

The modular monobore frac missile system accommodates any arrangement or number of pumps, enabling you to pump more efficiently.

This robust, large-bore single pipe with highly secure API 6A flanges is available in skid-mounted four- and six-pump configurations. The 7-in high-pressure line of the monobore missile is rated for high-capacity performance to 15,000 psi and 160 bbl/min. The system also features dual low-pressure line systems.

Instrumentation and the suction manifold are housed on separate skids.

For pump isolation, the Cameron plug valve can be replaced with check valves.

Onshore unconventional frac operations

Fully compliant to API 6A, the monobore frac missile’s flanges provide highly reliable connections that mitigate the risk of fluid leaks and washouts. This enables continuous and safer operations and more pump time per day.

Although the missile system is compatible with conventional flow iron and hoses, safety and reliability are further enhanced by using MonoFlex dual-connection fracturing fluid delivery technology to provide a flexible, erosion-resistant conduit to the frac pumps. With only two connections, MonoFlex technology greatly accelerates pad rig-up for multiple wells.

The large-bore monobore missile is adaptable to use the Cameron clamp quick-connect system (CCS30) to slash the connection time for small-bore frac hoses with any pump union type to a mere 20 seconds or less. Connections are also more reliable because the CCS30 is installed using a conventional torque wrench, avoiding the HSE risks inherent in conventional hammer unions.