Advanced Liner Installation Planning Analysis

Harnessing the power of DrillPlan coherent well construction planning solution

Optimize liner and liner hanger installation via comprehensive engineering analyses.

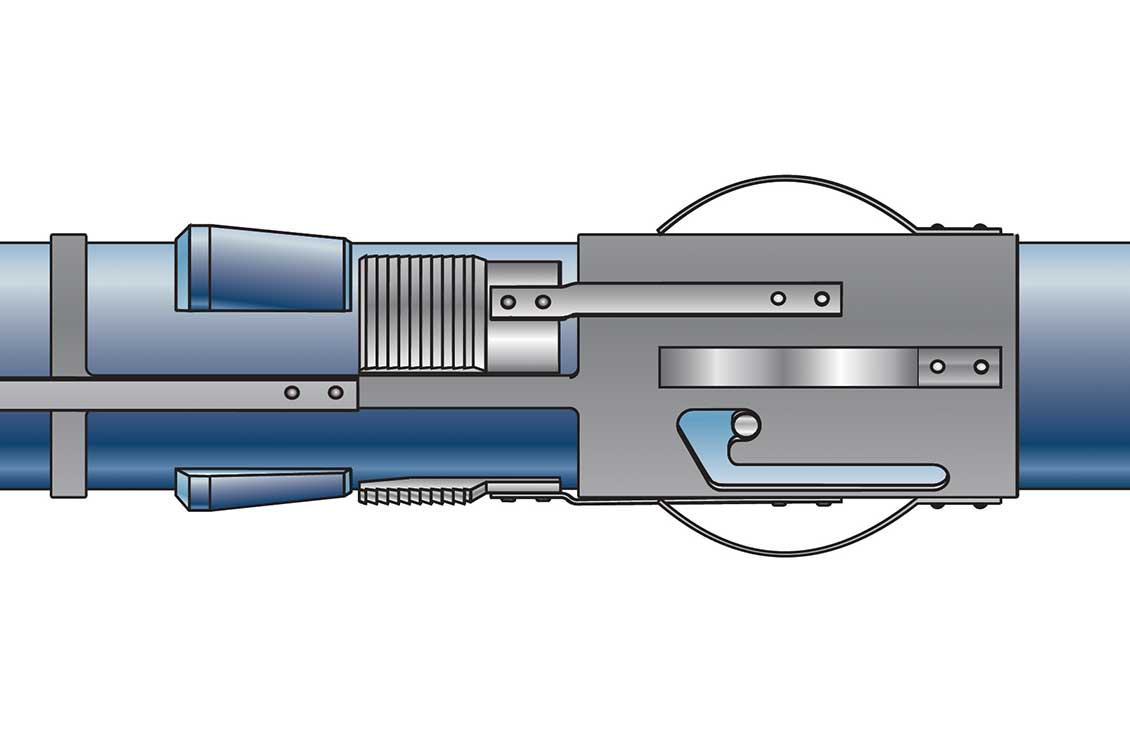

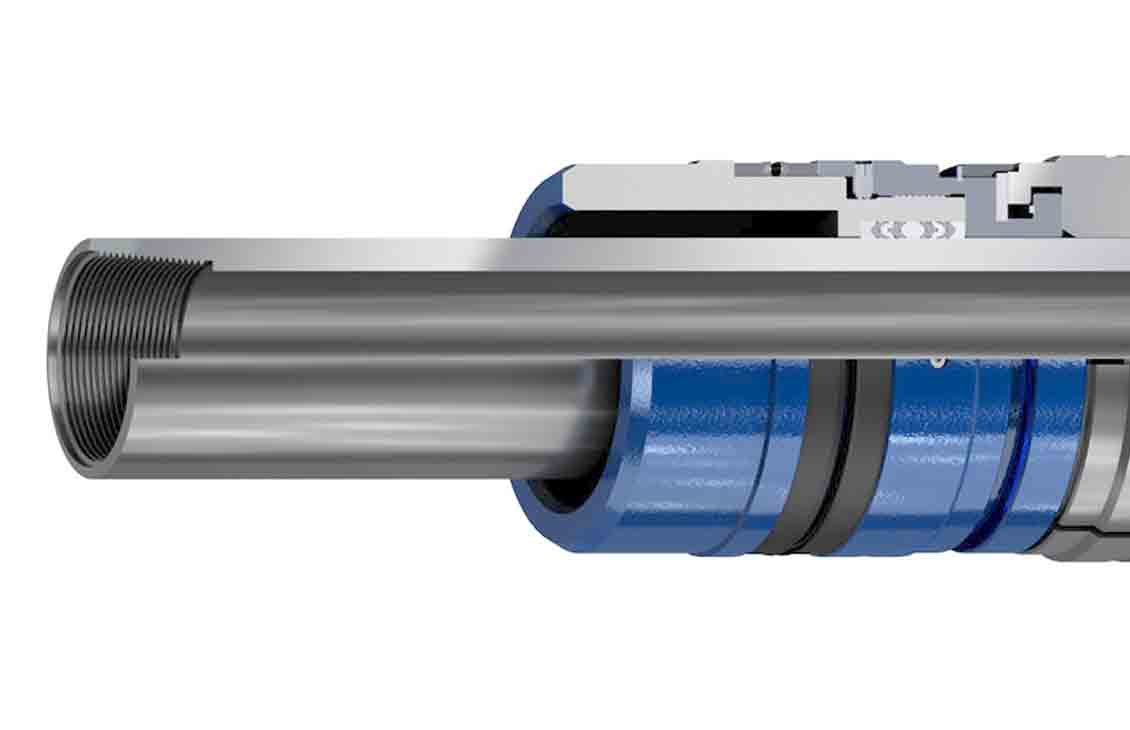

Liner hanger systems

Careful planning before and during installation can help operators prevent issues that significantly impact NPT. Since 1952, our dedicated team of liner hanger experts has offered customized support, a commitment to excellence in execution and service quality, and optimized workflows with zero NPT. We're backed by an extensive global track record to maximize efficient processes and effective outcomes.

COLOSSUS liner hanger systems have been deployed worldwide with a 99.5% operating efficiency.

The complexity of each application depends on a number of factors, such as well deviation, temperature, and pressure. With a range of available features, COLOSSUS liner hanger systems have a history of success in the most straightforward to the most challenging environments around the world.

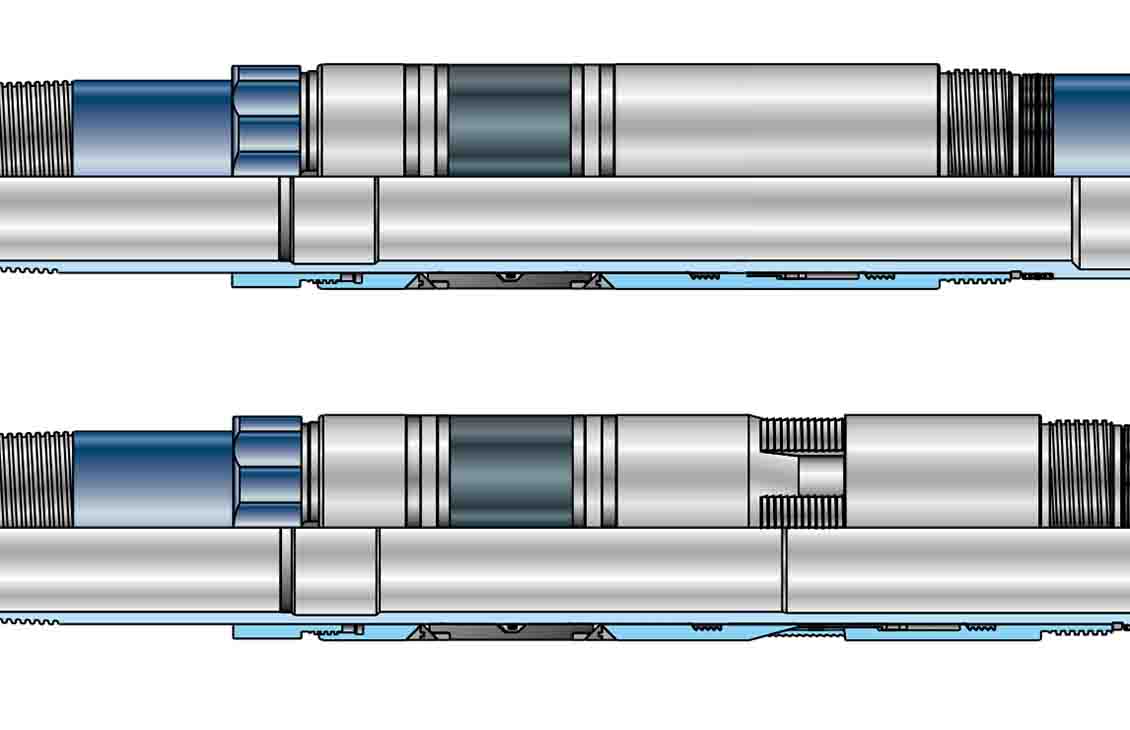

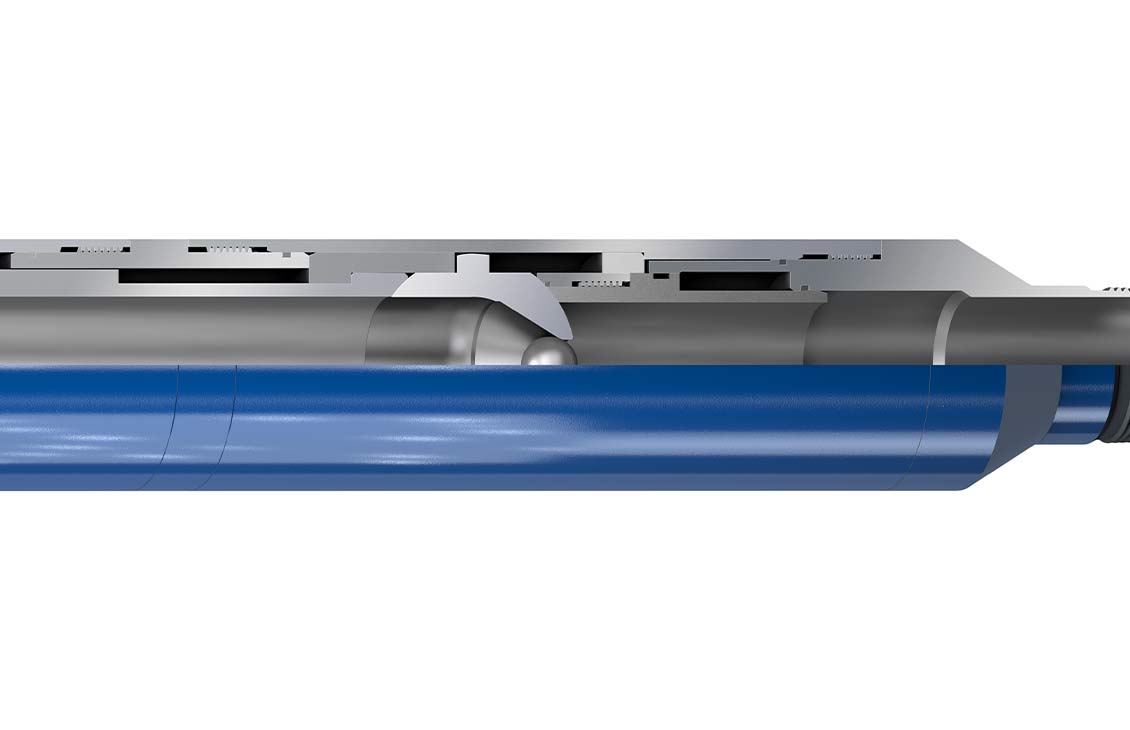

Deploy heavy and long liners in drilldown applications, even in deep land, deepwater, and HPHT wells, to save time and enable rotation. View

Run long and heavy liners with confidence, even in HPHT conditions, with or without liner rotation during running or cementing. View

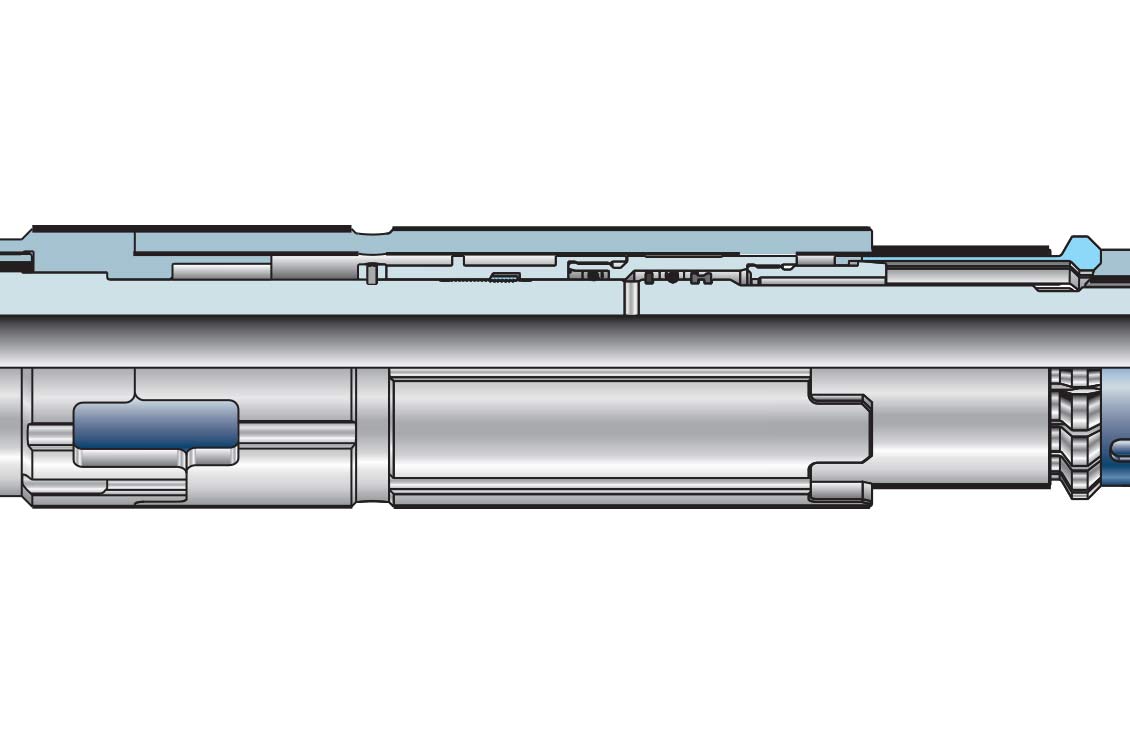

Run light and medium-weight liners in wells where the workstring can be manipulated to set the hanger. View

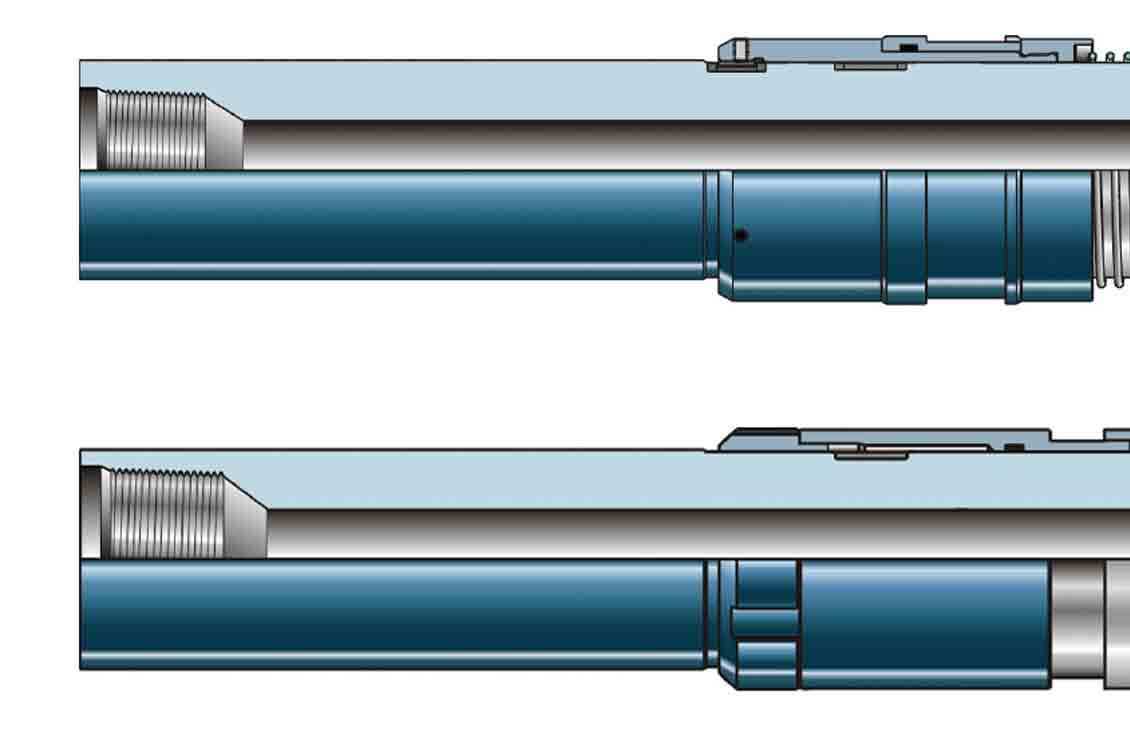

Choose a reliable packer rated to 10,000-psi [68.9-MPa] differential pressure. View

Run this V0- or V3-qualified packer above the COLOSSUS CMT liner hanger system in HPHT wells to enable drilldown and rotation. View

Run liners and release without rotation—ideal in high-inclination wells. View

Mechanically or hydraulically set liner hanger systems that require high torque to drill the liner. View

Maintain pressure integrity for liner hanger and liner top packer operations. View

Save time running and setting liner hanger systems, and reduce pressure surges. View