ProActive

Drilling asset management services

Drilling may not always be predictable, but your costs can be.

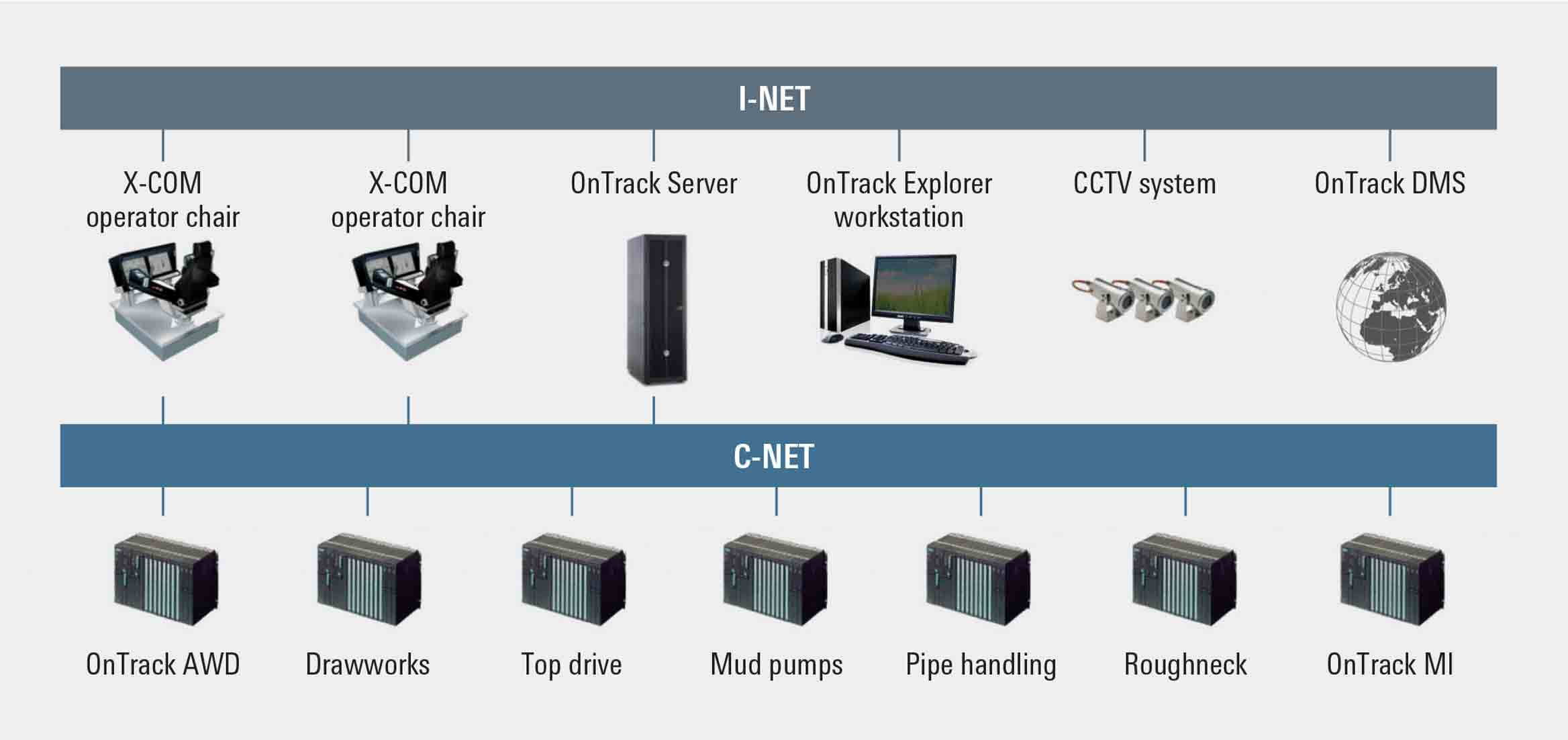

Integrated drilling controls system

With the OnTrack integrated drilling controls system, various types of drilling equipment and processes can be integrated into one system. This provides the driller and assistant driller with optimal monitoring and controls, together with key decision-making information. The integrated system ensures that all control systems from other suppliers fit together correctly and are integrated properly.