Signature

Quartz gauge

Obtain precise pressure measurements in a wide range of environments with reliable downhole recorders.

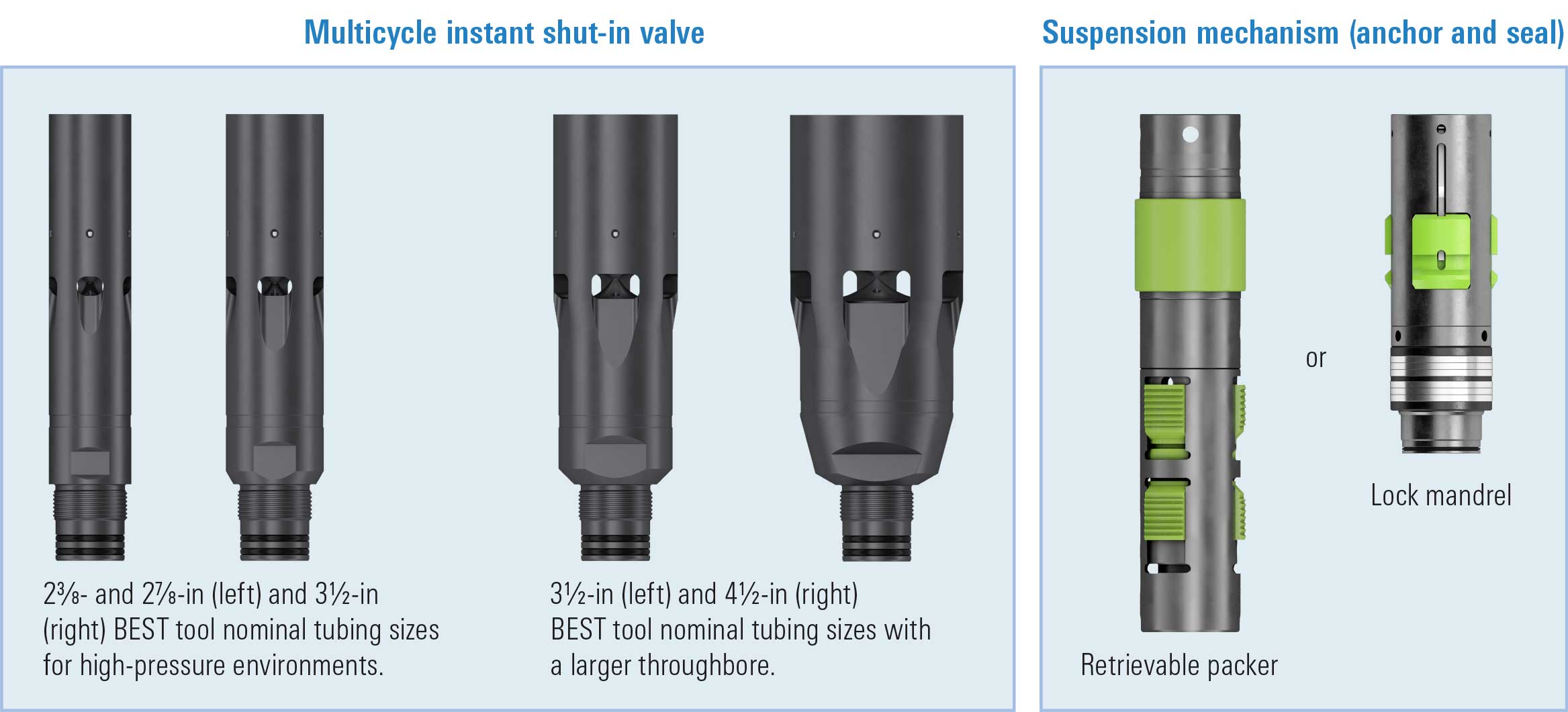

Buildup evaluation shut-in tool

Deliverability testing in exploration and appraisal wells

Multizone testing in injection and production wells

Skin evaluation and depletion assessment of producing wells

Land and offshore environments

The BEST buildup evaluation shut-in tool is suitable anywhere there is a need for efficient and cost-effective acquisition of high-quality downhole formation pressure data with minimal impact from wellbore storage effects.

In new wells, the tool provides an alternative for well testing where the cost and logistics associated with conventional testing methods are prohibitive or when rigless operations are required. The tool is used to determine key formation parameters such as reservoir boundaries, fluid type, and deliverability. In production wells, the BEST tool is used for periodic testing to determine reservoir depletion and assess the effectiveness of production-improvement interventions such as stimulation and reperforation.

Installed inside the borehole close to the formation, the BEST tool provides a downhole shut-in that reduces wellbore storage, resulting in faster buildups (especially in gas wells), shorter operational time, and minimized production downtime—saving costs.

Early stages of pressure buildup are dominated by the compressibility of the fluid in the borehole. This is known as a wellbore storage effect and can mask pressure responses characteristic of the formation. The BEST tool minimizes wellbore storage effects by shutting the well downhole. It further enhances the interpretability of the early buildup pressure data through its instantaneous valve shut-in action. This enables a more accurate characterization of the near-wellbore region.