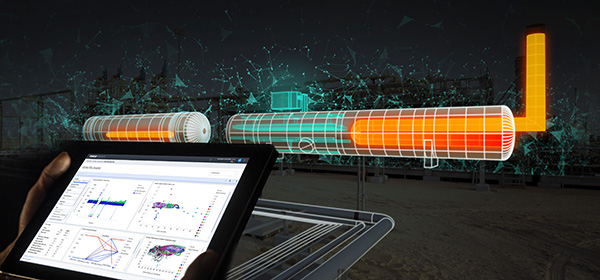

Natco Dual Frequency

Electrostatic treaters, coalescers, and desalters

Use both AC and DC power to significantly improve processing vs. conventional AC electrostatic technologies.

Maximize electrostatic dehydrating and desalting performance and reliability

Process Live service is the software-as-a-service digital solution that maximizes electrostatic desalting and dehydrating performance and reliability.

Electrostatic crude oil dehydrators and desalters are widely used onshore and offshore to lower basic sediment and water (BS&W) and pounds of salt per thousand barrels (PTB) from crude oil; however, maximizing electrostatic performance of these flexible, compact systems depends on manual intervention by operations personnel to optimize performance.

If the electrostatic desalter is not optimized, the result is overspending on demulsifier dosing, heat, freshwater, and accelerated refinery catalyst poisoning, which add to the operational expenses required to meet outlet specifications and avoid contractual penalties or loss of throughput.

Operator of a Middle East oil production facility eliminated desalter downtime by using Process Live data-enriched performance service to enhance expertise in analyzing data from the facility’s numerous monitoring and control systems.

LEARN MOREYou pay a high price for loss of reliability and throughput. Process Live Uptime Assurance for electrostatic treaters lets you proactively manage power unit reliability with prognostic health monitoring and to identify critical events. Electrical system feedback allows proactive maintenance of the power unit and the treater.

Process Live Uptime Assurance for electrostatic treaters helps you optimize performance of

Process Live data-enriched performance service is a multifaceted offering for uptime assurance, process optimization, and greenhouse gas (GHG) control. It integrates digitally enabled equipment, collaboration with OEM experts, and maintenance to enhance asset life cycle management.