Natco Dual Frequency

Electrostatic treaters, coalescers, and desalters

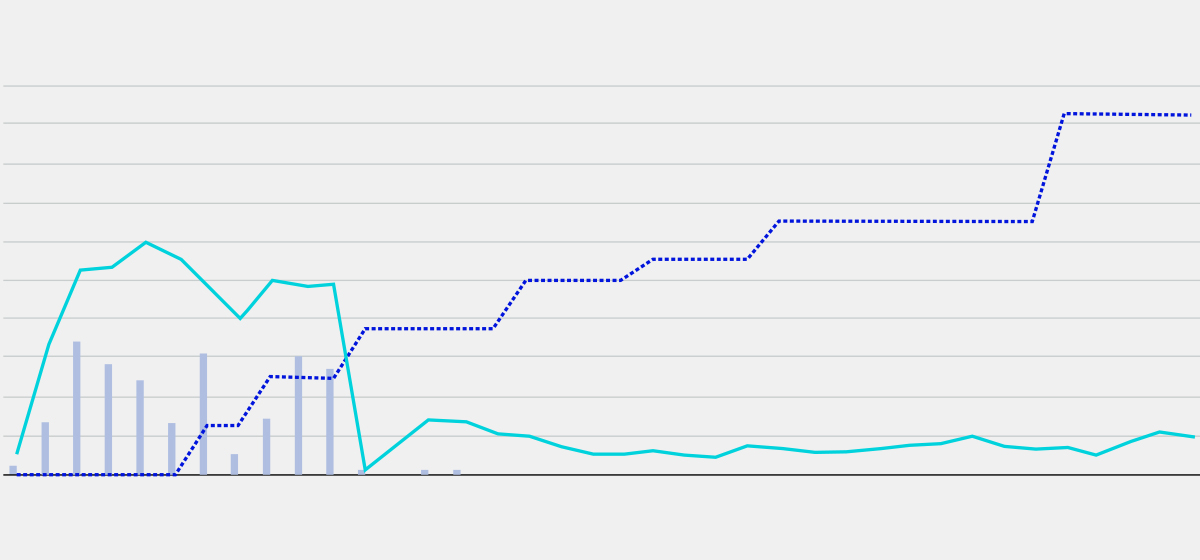

Use both AC and DC power to significantly improve processing vs. conventional AC electrostatic technologies.

For crude oil dehydration and desalting using tuned emulsion breaker chemistry

Demulsifiers ensure that the residual water and salt content in crude and the oil content of separated water meet required specifications. They disrupt the ordered structure of the natural surfactants that stabilize the emulsion, enabling the dispersed droplets to coalesce and form larger droplets that move to the oil/water interface.

Cost-effective demulsifiers are formulated for your specific application or facility. A wide range of factors—including injection location, nature of the oil and produced water, environmental requirements, and equipment and facility limitations—are thoroughly evaluated to minimize operational disruption and cost.

A holistic approach to separation of oil and water is beneficial to the overall performance of the facility.

In the first three wells, viscosity measured at surface decreased by up to 85%, prompting adoption of the custom-engineered product for additional wells offshore Qatar.

Read Case Study