Techlog drilling interpretation

Drilling monitoring and analysis for remote decision support

Drilling monitoring and analysis for remote decision support.

In 2021 Neptune Energy (now part of Vår Energi) made the decision to improve the workflow for their well construction planning process and implement this in one of their development fields. The field had complex subsurface challenges such as faults and natural fractures, formation instability, pressure variations in the overburden, and depleted reservoirs and these challenges increased operational cost considerably due to high NPT. Therefore, a higher level of risk awareness between subsurface and well planning teams was needed, to design and drill wells that would be optimal in construction and placement whilst avoiding operational incidents and resulting NPT.

A new workflow was implemented for the planning of well trajectories, utilizing cloud services and software applications including DrillPlan™ coherent well planning and engineering solutions, and DrillOps™ intelligent well delivery and insights solutions to automate and improve various processes, and Techlog™ drilling interpretation for detailed well analysis.

The typical workflow for planning well trajectories involves manual data transfer between the subsurface and drilling teams, with updates provided occasionally or on demand, and requiring manual intervention when any changes occur. This can lead to potential errors and delays. Whereas the new workflow includes a dedicated cloud service that automates updates of formation models, drilling windows, and formation tops, reducing the need for manual interventions. This automation ensures that mud weight window (MWW) boundaries, formation tops, fault positions, and drilling risk registers are updated automatically with changes in well geometry and well trajectory.

As the well planning tool selected, DrillPlan solutions enhances project management by assigning tasks, auditing processes, sending notifications, and tracking history of original design, updates, review, and approval. It supports detailed engineering workflows to validate and deliver well designs, including components like trajectory, BHA, wellbore schematics, cement program, and drilling fluids’ properties. Automated validation, sensitivity analysis, and drilling emissions management are also part of the process.

Activity planning included a sequence of operations for each phase of the well and detailed execution instructions.

The integration of DrillOps solutions ensured a seamless transfer of data from planning to operations, enabling the reporting process to be optimized through the generation of activity programs using templates from DrillPlan solutions, which included dynamic tables, schematics, text, and graphs. Additionally, the end-of-well report (EOWR) was generated using templates from DrillPlan solutions, incorporating some dynamic information and utilizing the full well report (FWR) from DrillOps reporting.

DrillOps solutions used real-time data and contextual information for AI-driven monitoring, predictive analytics, sending alarms and recommendations, and geomechanics updates during operations. The use of real-time monitoring enabled various well conditions to be monitored simultaneously including volumes while drilling and tripping, torque and drag (T&D) trends and limits, shock and vibration (S&V), surge and swab (S&S), and washouts. By integrating real-time data with contextual information better monitoring and decision-making during operations was enabled. This helped in adjusting parameters like mud weight to avoid issues such as hole collapse.

The performance tracking tool selected was DrillOps performance insights, which uses both high and low-frequency data to compare wellbores. DrillOps procedural adherence was used to ensure activities and instructions defined in the digital drilling plan, fed through from DrillPlan solutions, were followed.

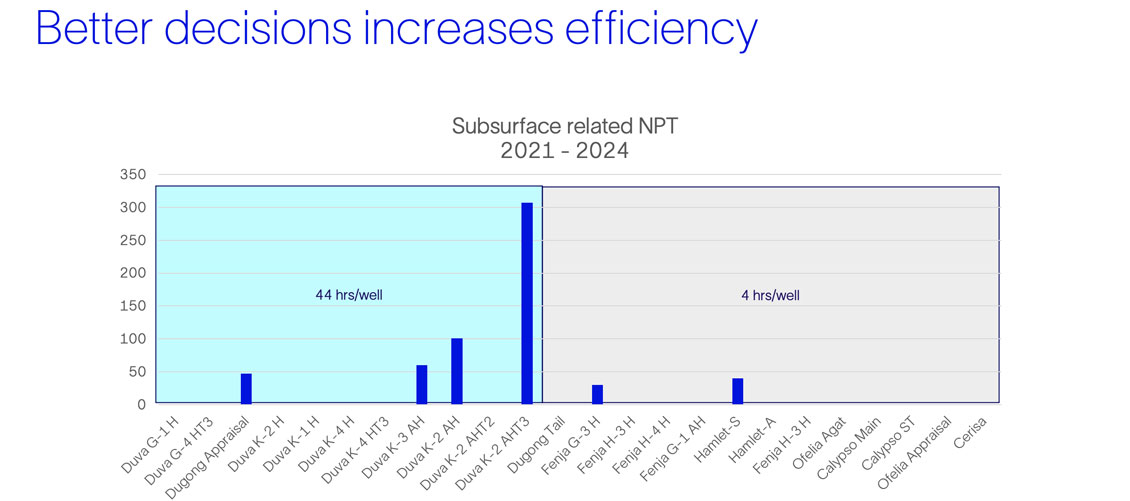

Since implementation the new workflow has significantly reduced subsurface-related non-productive time from 44 hours to less than five hours per well.