In this article

- Understanding circularity and its practical applications for your business.

- Challenges and opportunities in shifting from linear to circular models.

- How to design your own circularity management strategy.

As the world grapples with the challenge of exceeding its planetary boundaries, innovative solutions that simultaneously take their surroundings into consideration have become ever more critical—which is where circularity comes in. Circularity remains one of the most promising paths for industrial players looking to not only be more resilient but thrive, all while reducing their environmental impact.

But what does circularity mean, in fact? For all its usage, the term remains significantly misunderstood. The way we (and many other experts see it), circularity is a systematic approach that aims to eliminate waste and pollution, minimize material consumption, circulate parts and material at their highest value, and regenerate nature. And it’s now more important for business than ever before.

Going from a linear to a circular economy

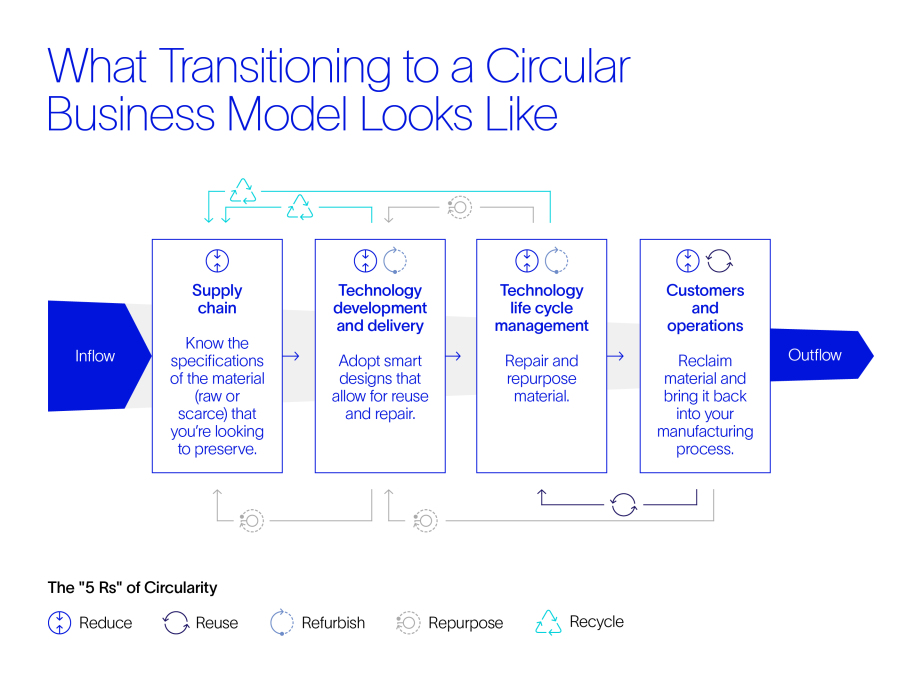

Our world today operates mainly on a linear model: products are made, used, and thrown away. This leads to a high consumption of finite and nonrenewable resources. Take critical minerals as an example, which play a vital role in the transition to renewable energy. Highly consumed or already rare, these minerals must be utilized carefully to ensure energy access for the benefit of all and not just a few. Optimizing their usage through the five main principles of circularity—reduce, reuse, refurbish, repurpose, and recycle—can enable the broader access to energy we’re all striving for.

A circular approach like this reduces environmental impact by narrowing, slowing, and closing resource consumption. Designed to mimic nature, it replaces the linear model of “take, make, and dispose” with a model where one process’s waste becomes another’s input (here’s a good oil and gas example). By better understanding materials’ durability and lifespan, circular models minimize our dependency on raw materials and production of unnecessary waste, thereby giving nature the space it needs to regenerate.

And let’s not forget that circularity doesn’t stop at optimizing (rather than maximizing) resource usage. It also emphasizes

- efficiently capturing and utilizing energy

- sourcing resources locally and from diverse sources

- sharing information to make the best use of available resources.

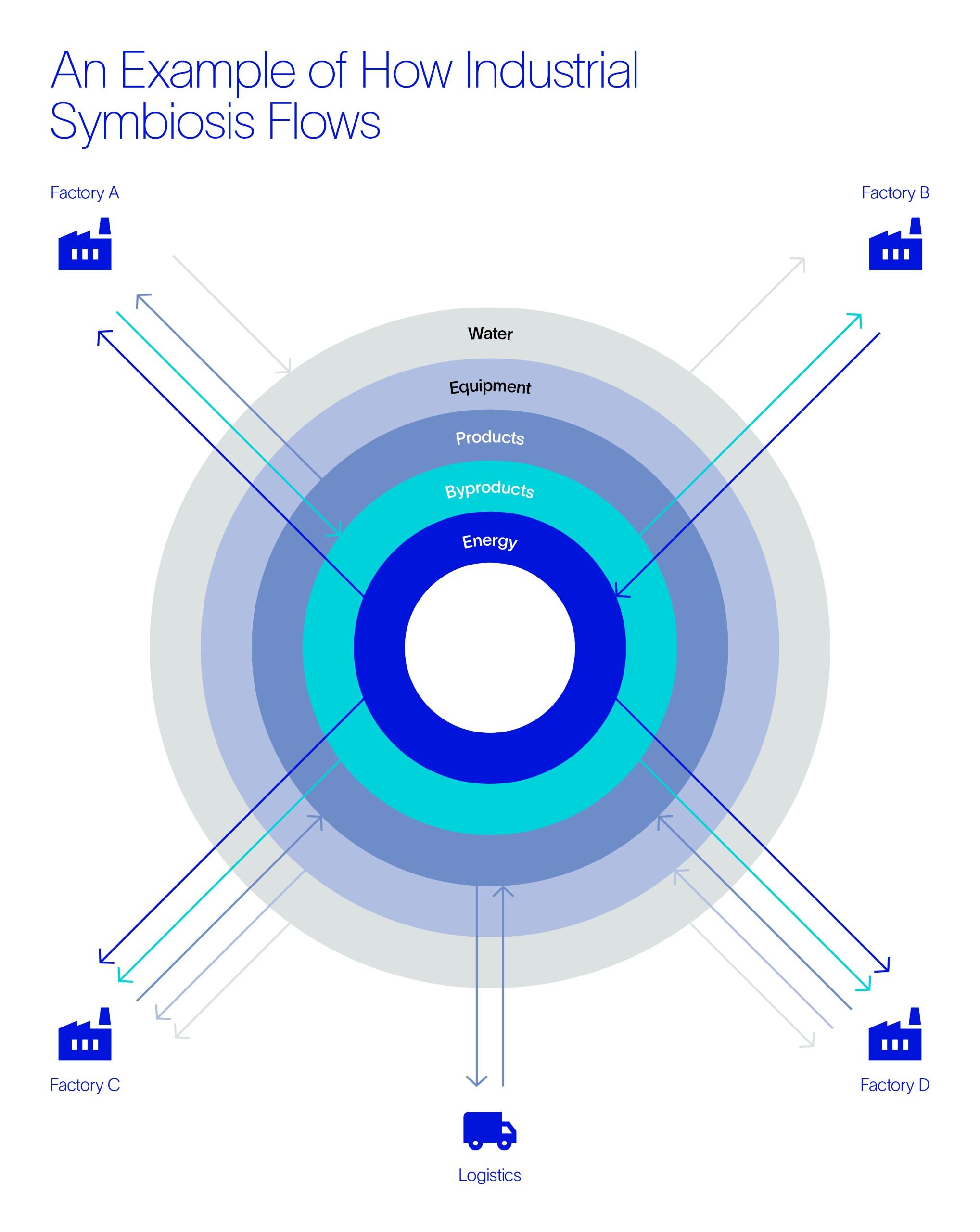

Industrial symbiosis is but one example of such cooperation. This approach promotes industries exchanging and sharing energy, water, material waste or side streams, logistics, capacity, expertise, equipment, and information at a local level. It requires a higher level of trust, legal support, and long-term vision than what most business leaders are used to, but it’s effective in enabling partners to optimize their resources.

The challenge of transitioning to circular models

One of the primary objectives of a circular economy is to decouple economic activity from the consumption of natural resources, thereby reducing the impact that business growth has on them. Not only is this sensible from a sustainability point of view, but it also incentivizes businesses to better manage their resources while saving costs.

At this point you might be wondering, if the circular economy is positioned as a resilient business model that’s also good for people and the planet, why aren’t more companies adopting it?

While circularity holds great promise, transitioning to a circular economy involves a wide breadth of factors:

- changing entire business models

- customer adoption

- regulatory support

- value chain transparency

- knowledge gaps

- shifting traditional processes across product design, manufacturing, and distribution.

Designing your own circularity management strategy

Should you be interested in adopting circularity, begin by reviewing and mapping your activities and interactions: How much material do you use to produce or provide services, such as food, textiles, or technology? Is this material renewable? The analysis of material consumption for products requires not only the “cradle to gate” approach but also the “cradle to grave” approach, especially for products that require fossil fuel energy, water, or consumables during usage.

Here are a few steps we suggest you follow:

- Assess material usage—Make a screening life cycle analysis to assess the quantity of material you use from supply chain all the way to the end of your product or service’s life. This helps you map out your value chain, along with the boundaries you can influence, and identify opportunities for improvement.

- Critical material analysis—Different materials have different impacts. A critical analysis from multiple angles (supply chain, environmental, and social) of the risks associated with each material helps you identify hotspots to focus on.

- Understand your business model—Once you've identified your hotspots, you need to understand the business model associated with consumption to better enable a transformation. Identify your customers, key partners, revenue streams, and expenditure.

- Training—For everyone to understand the transformation this requires, make sure all stakeholders (especially those leading the implementation of your circular economy strategy) are properly trained in circular economy principles.

- Collaboration—All stakeholders in your product’s value chain need to work together to break the silos and share a common perspective. This means stakeholders both within and outside your company, including suppliers, designers, customers, and end-of-life recyclers.

- Customer mindset shift—From a marketing perspective, a mindset shift is needed among customers. This involves moving from a focus on product ownership to embracing remanufactured products and usage instead of ownership. It also calls for valuing optimized over maximized performance.

- Key performance indicators—Setting performance metrics to track business value and natural resource conservation is essential for progress visibility.

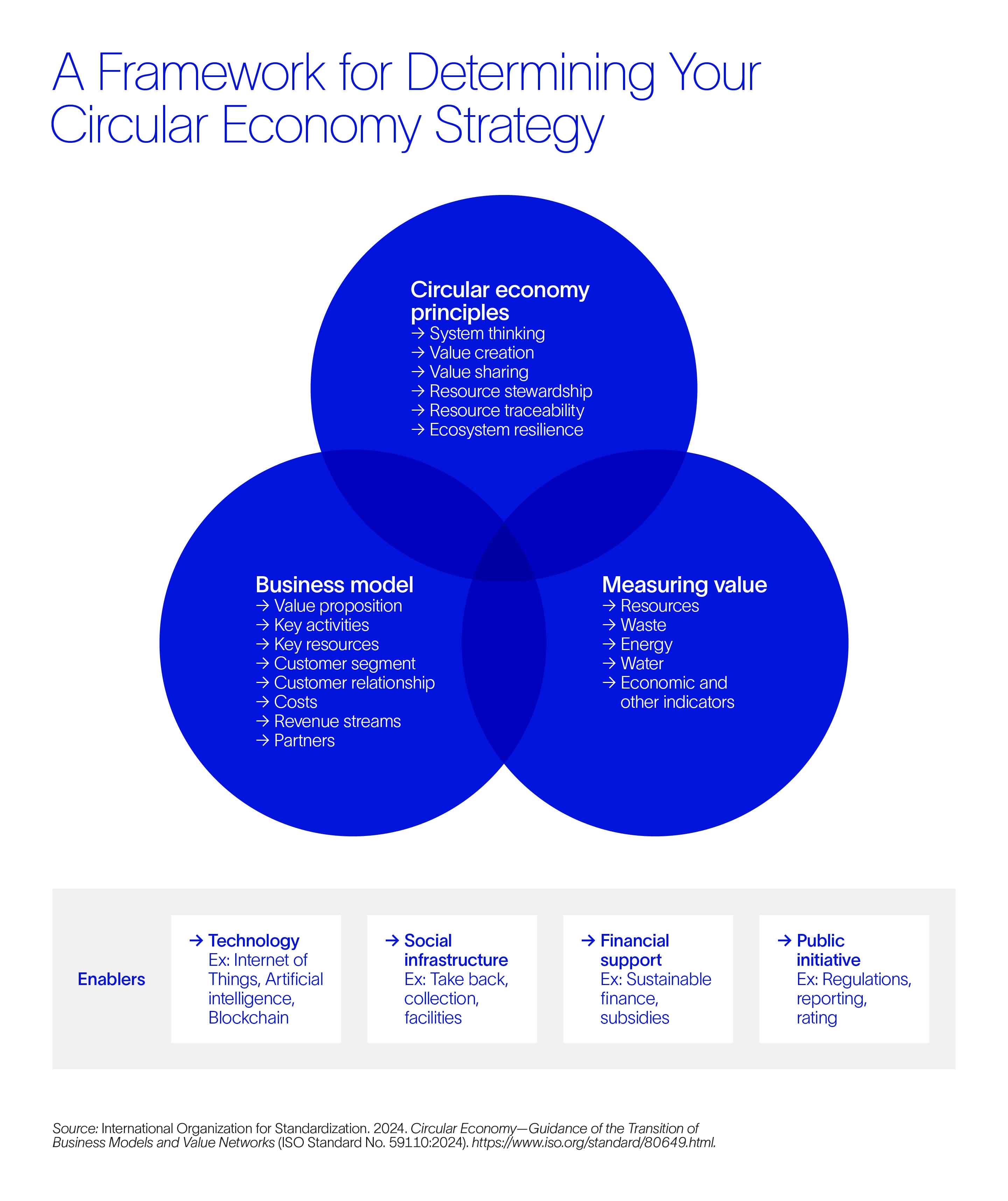

A summary of the key strategic elements from Standard No. 59010 of the International Organization for Standardization is summarized below with its three pillars:

- The circular economy principles, including resource stewardship

- The business model with its circularity value propositions

- The measurement required for continuous improvement.

In addressing global challenges, we need solutions that effectively reduce waste and promote mindful consumption of materials, particularly those at risk of scarcity. Embracing circularity necessitates a transformation in business practices, prioritizing resource utilization over consumption. It refocuses our attention on purpose and value, encouraging us to actively consider our desired contributions, along with the collaborations and connections necessary to achieve them.

Circularity is an approach that offers a significant opportunity to improve the planet's well-being. Rather than resisting the required business model shift, it's crucial to explore how the circular economy can benefit your specific sector. After all, it can lessen your reliance on natural resources while simultaneously generating business value.

Good for the planet. Good for you. Good for everyone.