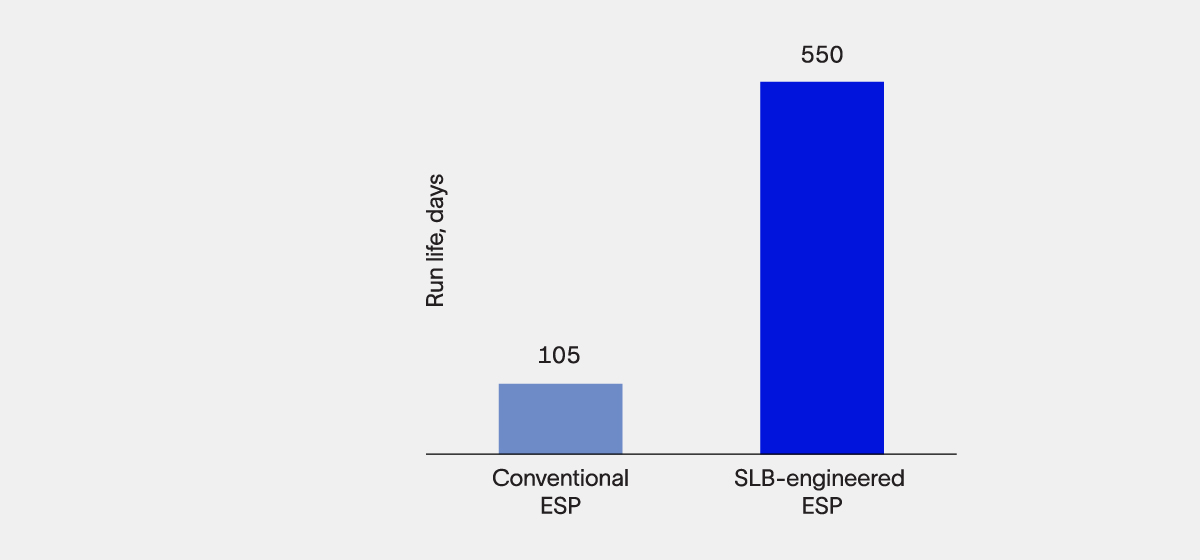

案例分享 Engineered ESP Completion Increases Pump Run Life >400%

Permian Basin operator also improves well uptime from 85% to 96%.

Vortex gas separator assembly

Effectively remove free gas from produced fluid with the VGSA vortex gas separator assembly. By venting this gas to the annulus, the separator prevents cycling, gas lock, and cavitation, resulting in a stable motor load and increased run life. By eliminating pump degradation caused by free gas, the VGSA improves pump performance and lifting operations—ultimately increasing production.

The VGSA assembly operates over a broad range of flow conditions and features a patented, abrasion-resistant construction suitable for gas-cut oil wells permitting annular gas production, gas lift-to-ESP conversion wells, and dewatering applications.

Efficiently separate gas from produced fluid

Natural gas separation occurs because of the differences in density and buoyancy between the gas and the liquid phases.

Mechanical gas separators are classified as either static or dynamic. Static gas separators are designed to keep free gas from entering the pump—without applying any additional mechanical force. They provide a tortuous path that turns the fluid stream down toward the inlet ports. Some of the free gas accompanies the liquid to the intake and a portion is separated, limiting overall separation efficiency.

Dynamic gas separators, on the other hand, impart energy to the fluid to separate the vapor from the fluid. The VGSA assembly is a dynamic gas separator that uses vortex action and improved hydraulics to separate at higher fluid flow rates than previously possible.

Permian Basin operator also improves well uptime from 85% to 96% in a gassy unconventional well with extremely unstable inflow.

Read case study