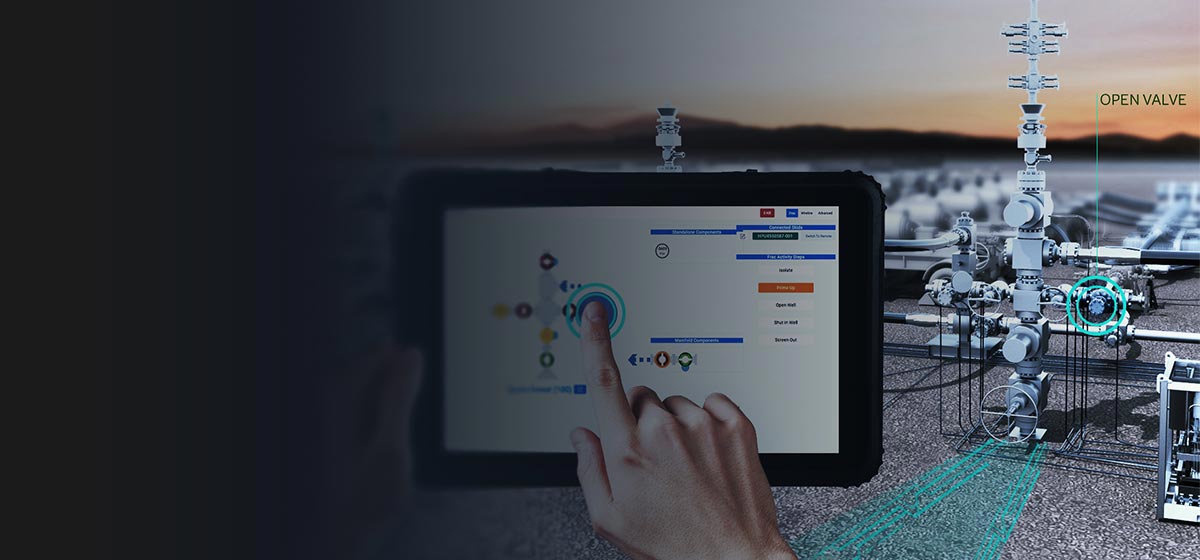

Flowback Wireless Advisory Platform

Real-time access to accurate flow rates and pressure during flowback operations

Automate data delivery from unconventional wells.

Cameron flowback services use the flowback wireless advisory platform to automate collection of and remote real-time access to operational data during flowback operations:

Cameron flowback services use basin-specific techniques and technologies to effectively handle solids removal and fluid separation to clean up your well, making it ready for production.

Every job is backed by The Cameron Service. You can rely on us across all major North America basins as your trusted partner for services and equipment that consistently deliver the highest levels of performance.

Our multiskilled technicians are on site throughout the entire job, fully prepared to handle screenout contingencies that may occur during hydraulic fracturing operations and to thoroughly clean the wellbore without delay.

The objectives of initial flowback and well cleanup are straightforward: Recover the fracturing fluid that was pumped into the well and screen out from the flow stream the remnants of the isolation plugs that were drilled out, along with any other solid debris that may have accumulated in the wellbore.

Once the well has been cleaned up, the well testing phase typically begins 48 to 72 hours afterward. During well testing, hydrocarbon is evident. A plug catcher and sand separator remove any remaining solids to prevent damage to downstream equipment. A three-phase test separator is deployed in sequence to separate out the gas, oil, and produced water and measure the flow rate of each.

Cameron understands that achieving those objectives is critical for conducting a well test that accurately represents the production potential. Incomplete fluid and solids removal negatively biases test measurement and subsequent performance. That’s why our flowback and cleanup operations are fit for basin, not one size fits all. Equipment and services are further tailored for your well’s conditions, including

Optimize frac operations with reliable equipment, services, and options for automation and digitalization.

Digitally enhance and automate your operations to transform your frac fluid delivery performance.

Rely on installation, inspection, maintenance, and repair services for frac and flowback equipment.

Solutions for consistent and continuous maximum performance in your hydraulic fracturing operations.

Explore more