Cement Bond Logging

Sonically measure the bond between casing and cement including slim and HPHT wells

Measure the bond between casing and cement using the industry standard.

弃井是不可避免的。无论海上还是陆地,每一口井最终都必须面临退役。但您并不能总是一开始就知道封堵与弃井 (P&A) 是一项简单的操作,还是一项复杂的、资本支出密集型的作业,才能符合准则和监管要求。一些关键数据的缺失,尤其针对一些老井,将使情况更加复杂。提前了解是否可以进行无钻机封堵与弃井作业,将显著降低成本并推动成本可预测性。

优化封堵与弃井的作业时间和成本,始于屏障评估。我们成熟的可扩展的技术和服务组件能够评估和考核井筒完整性,从而发现无钻机封堵的作业机会,为从容地封堵每口井并控制成本铺平道路。凭借我们的封堵与弃井服务,我们可以提供有针对性的、模块化的、甚至完全集成的封堵与弃井服务。其广泛性和灵活性使我们始终能够为您找到所需的答案。

几十年来,凭借井筒工程和集成的数字能力,我们已为广泛的技术组合建立了全球影响力,同时还构建了一个开放的合作伙伴网络。

以下是我们如何帮助您实施封堵与弃井的方案,以实现最小环境足迹和成本节约、确保井筒安全,并符合监管要求。

采用先进的固井和树脂基解决方案,即使应力状态发生变化或发生流体接触,也能保持永久、无泄漏的屏障,确保井口安全密封。

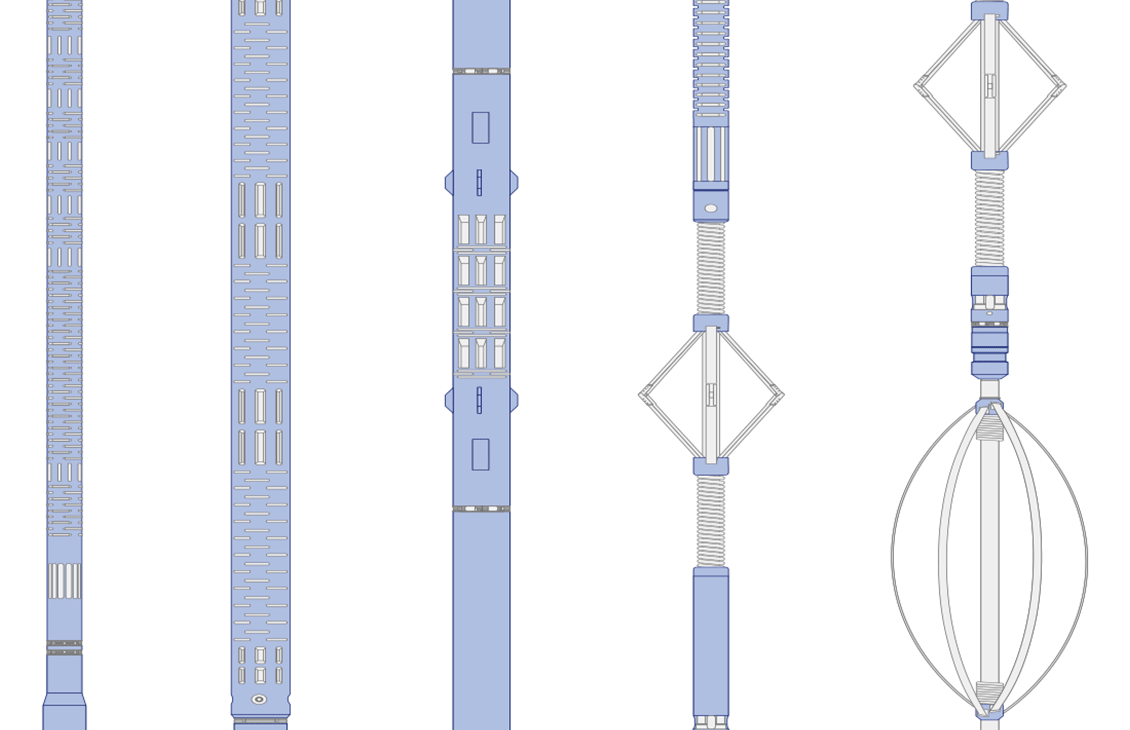

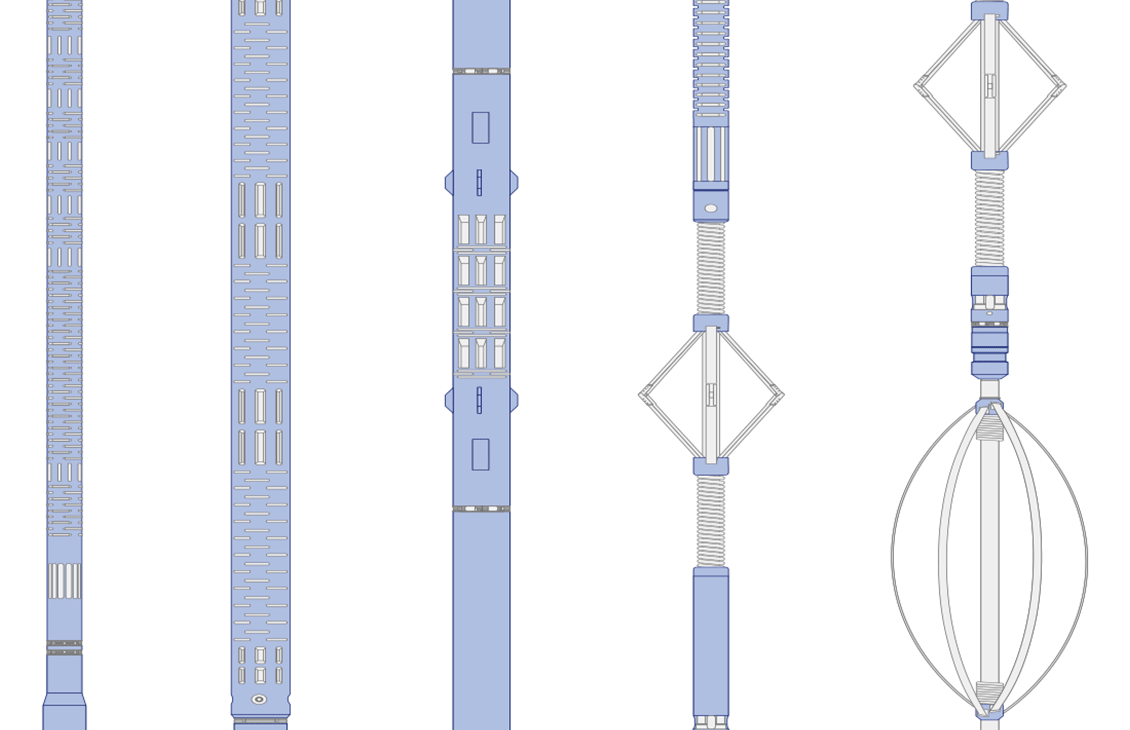

在不需要拆除内管的情况下,全面评估水泥和套管,以更经济性措施指导封堵与废弃。

Definitively determine well integrity in a single run without removing inner pipe

Evaluate the A- and B-annulus in a single run for reduced costs in P&A well decommissioning operations.

Sonically measure the bond between casing and cement including slim and HPHT wells

Measure the bond between casing and cement using the industry standard.

Noninvasively evaluate casing integrity without having to pull completion tubing

Identify and quantify damage and corrosion in single and double strings without pulling completion tubing.

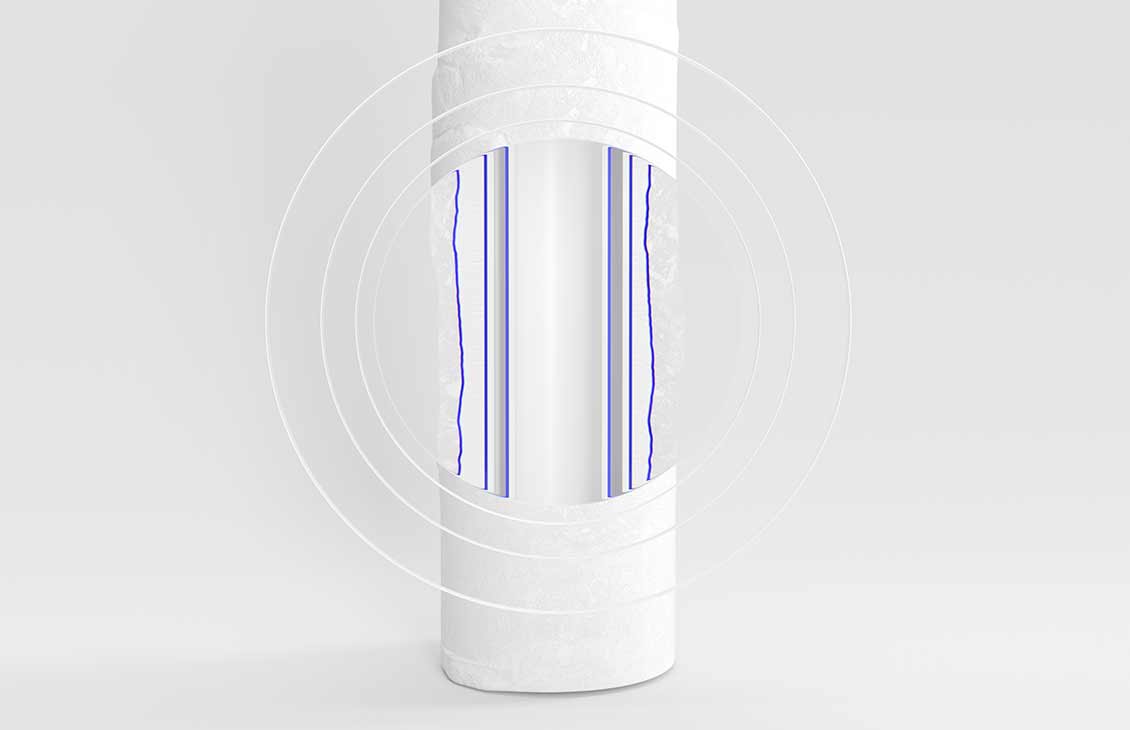

Confirm zonal isolation, centralization, and cement bond quality in real time

Fully characterize well integrity around the entire casing circumference and across the annular environment.

Accurately detect defects in downhole tubulars, completion components, and casings

Identify and visualize corrosion and pipe defects by measuring the well’s inner radii.

通过钢丝作业高效部署可靠的井筒屏障和隔离方案,兼具操作简便性和成本效益。

Precisely install barriers by placing retrievable and permanent plugs with real-time control and data

Efficiently riglessly deploy digital slickline with real-time control or complement rig-based operations.

Identify and remedy damaged tubulars and reliably manage isolation with plugs

Lower rig deployment to save costs and time by managing plugging tasks with slickline mechanical intervention.

精准切割各类管柱(包括套管、钻杆、连续油管和生产油管),实现高效回收,并可处理卡管事故。

Precisely target explosive charges to effectively rupture and split heavyweight pipe and collars for recovery

Cleanly and smoothly cut tubulars in in any fluid environment without the time and cost of cleanout shots.

Efficiently cut up to 8 slots simultaneously and 200 slots in a single run with a highly combinable tool

Avoid explosives and enable new opportunities through production slot recovery within P&A activities.

Execute tubing cutting and punching and pipe recovery on digital slickline for precise control and certainty

Efficiently deploy digital slickline riglessly with real-time control or complement rig-based operations.

Automate tubing cutting for depth-accurate mechanical cuts in the most complex completion profiles

Skip the explosives and automate accurate mechanical tubing cutting, even in the most complex completions.

提供最先进的成套技术服务,包括高效管柱回收、剪切、密封和固井作业,全程采用无隔水管开放式海水弃井技术。

Optimize decommissioning with integrated capabilities and technologies of SLB and Helix Energy Solutions Group

Boost P&A efficiency and lower cost with innovative riser-based or riserless access to any subsea well.

Remove production tubing in open water with secure intervention riser system or subsea intervention lubricator

Secure gas and contaminants with environmentally compliant open-water removal of production tubing.