Pump systems for mine dewatering

Keep your mine dry, efficient, and compliant

Pump systems engineered for the world’s toughest mine dewatering challenges

Mine dewatering is crucial to maintaining safe and productive critical minerals operations. Uncontrolled inflow can halt mining operations, damage assets, and breach regulatory thresholds. Whether you're dealing with rainwater, groundwater seepage, or unexpected aquifers, SLB provides robust solutions tailored to your needs. Designed for mine operators facing challenging environments, our integrated solutions ensure efficient water management and improve safety and compliance—keeping your mine running smoothly.

Why SLB for dewatering?

Traditional vertical dewatering bores are often inefficient, requiring multiple boreholes and pumps that drive up cost and complexity—especially in deep or remote pits. SLB electric submersible pumps (ESPs) for mine dewatering are designed for directional (or slant) drilling and feature durable components built to last the life of the pit. A single directional well can replace more than 20 conventional wells, reducing capex while enhancing safety and sustainability. The ESP system is suitable for high flow rates of up to 330 L/s, supported by a submersible motor with a capacity of up to 1,300 kW (limited by the lift requirements).

Efficient water removal

Prevent flooding and equipment damage with our high-performance pumps engineered for harsh conditions.

Real-time adaptability

Effectively manage fluctuating groundwater levels and complex geological conditions.

Cost-effective operations

Reduce downtime and operational delays by positioning all dewatering hardware outside the mining area, ensuring compliance with environmental regulations while keeping mining costs in check.

Sustainable impact

Ensure minimal impact on adjacent water systems, safeguarding ecosystems while avoiding mining hazards caused by wet and unstable ground.

Built for harsh conditions. Proven in the field.

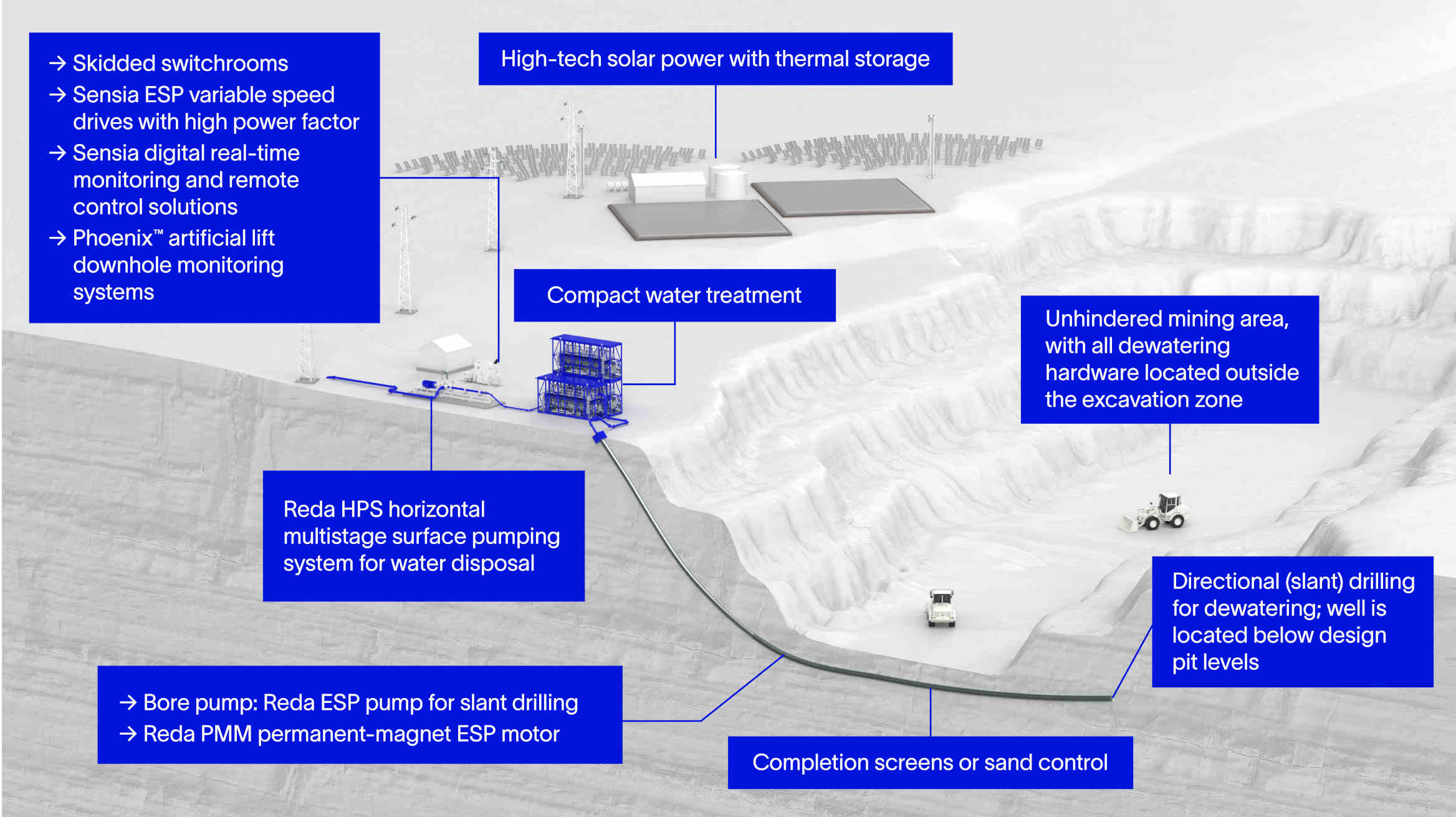

SLB integrated solutions, which use proven technologies to reduce emissions and environmental impact and are all managed through real-time remote technology, can provide efficient water disposal. Our approach is designed to achieve the lowest carbon footprint possible while enhancing operational efficiency for your mine. Central to our offering are Reda ESP™ pumps, ideally suited for horizontal directional (slant) drilling below design pit levels, powered by Reda PMM™ permanent-magnet ESP motors to further minimize environmental impact. Completion screens provide effective sand control, ensuring smooth operations. Our compact water treatment systems, coupled with Reda HPS™ horizontal multistage surface pumping system technology, facilitate precise water disposal management. Skidded switchrooms and variable speed drives, featuring the highest possible power factor, optimize energy use. Additionally, real-time monitoring and remote control capabilities enable precise downhole monitoring via specialized gauges. With high-tech solar power systems incorporating thermal energy storage, we deliver sustainable energy to power your entire operation.

Products and services

-

Well Construction

Extended Reach, Horizontal, High DLS, LWD/MWDFaster ROP & better well placement in extended-reach, horizontal, unconventional, pad, high-dogleg, and other challenging oil and gas well schemes.

-

Electric submersible pumps

Diverse ESP solutions for maximum productionBoost production in any environment, including conventional, unconventional, high-temperature, intervention-constrained, and offshore applications.

-

ESP Permanent Magnet Motors

Reduced energy costs and improved ESP performanceESP Permanent magnet motors have power efficiency, power factor, and power density and help lower electricity consumption.

-

Reda Maximus

Install-ready ESP motorIncrease production with our standard ESP motor, designed for conventional, unconventional, and shallow well conditions.

-

Reda HPS

Horizontal multistage surface pumping systemsCentrifugal pumps for oil and gas, mine dewatering, geothermal energy, carbon sequestration, saltwater disposal, and water desalination.

-

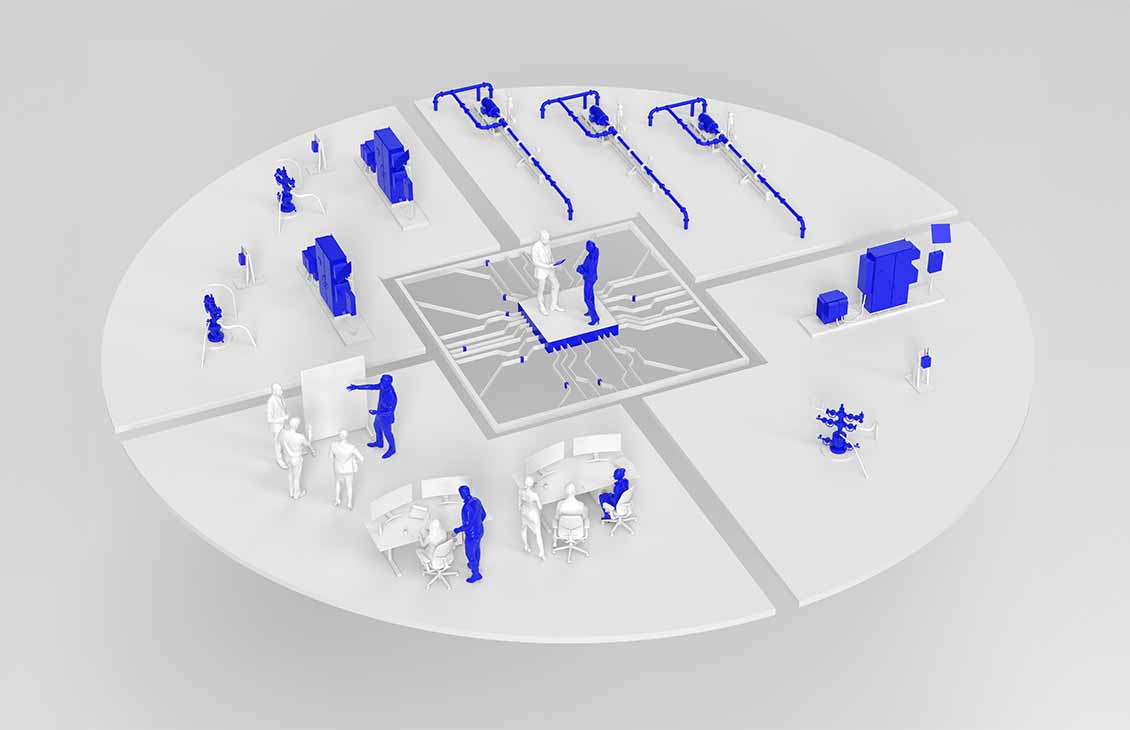

Intelligent Lift for Optimized Production

Take proactive action for continuously changing well conditions.Minimize downtime, reduce cost, and improve sustainability via optimized artificial lift performance.

-

Sand Control

Reservoir sand and fines managementExtend well production with gravel- and frac-pack services, fluids, screens, ICDs, and tools for openhole and cased hole wells.

-

Sensia ESP Variable Speed Drives

Minimize downtime with ESP drives designed for your applicationProlong ESP system life, minimize downtime, and reduce operating and installation costs

-

Gauges

Efficient monitoring of artificial lift performanceMonitor downhole performance with diagnostics and analytics needed to protect your pumping system.

-

Reverse Osmosis Systems

Eliminate dissolved salts from seawaterReverse osmosis systems achieve near total removal of dissolved salts from seawater used for injection or as desalter washwater.