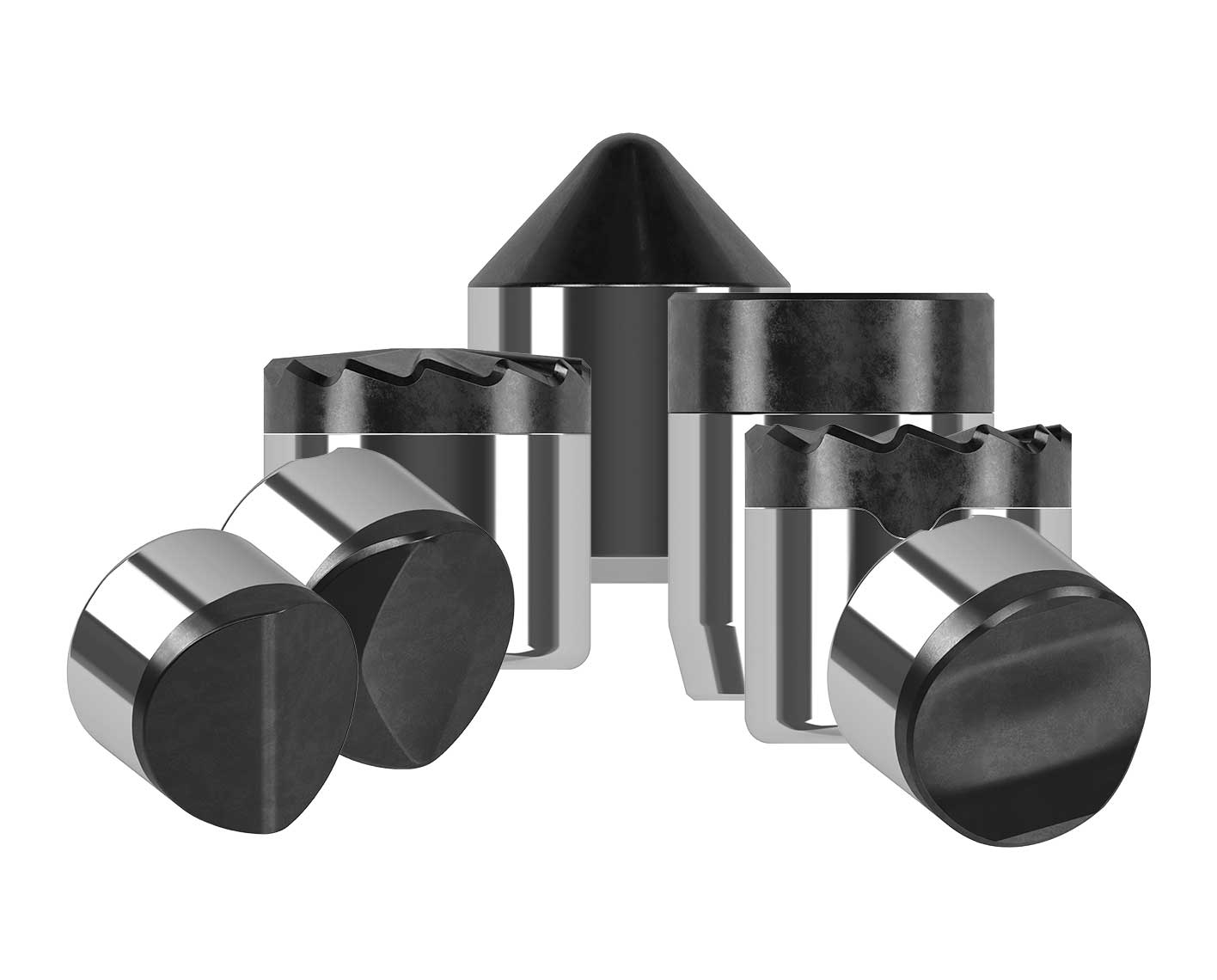

Shaped PDC cutters deliver efficiencies

The ridged cutting elements improve cutting efficiency, enabling our PDC bits to drill with higher ROP.

Innovative cutter elements enhance PDC bit efficiency

Polycrystalline diamond compact (PDC) bits are the workhorses of the oil field. Features such as cutter types, cutter layout, and blade geometry are continuously being evaluated and improved to deliver value and drive down drilling costs. Certification with the IDEAS™ integrated dynamic design and analysis platform ensures these bits offer optimal performance.

Bits with IDEAS platform certification are stable and produce less torque and stick/slip in transitional drilling. The risk of incurring time‑consuming and costly trips due to shock and vibration is greatly reduced.

PDC cutter technology

Our wide portfolio of application-specific PDC cutters enables us to customize and configure PDC drill bits to outperform in any drilling challenge, whether the motivations are driven by performance or economics. Our commitment to research and development—and rigorous field testing—ensures that all PDC cutter grades and shapes can exceed the needs of our customers.

PDC cutter design

The unique geometries of our cutting element designs improve the cutting efficiency and PDC bit durability. This enables our PDC bits to drill with higher ROP and increased footage to save drilling time and costs.

Stinger™

Conical diamond element

- For hard and high-impact formations.

- Featuring the industry's first 3D cutting elements.

Enduro 360™

Rolling diamond cutting element

- For hard and abrasive formations.

- The industry's only rolling element that actually cuts rock.

Thermal-resistant diamond cutting element

- For hard and abrasive formations.

- Mitigates effects of thermal degradation (cutter cracking and chipping).

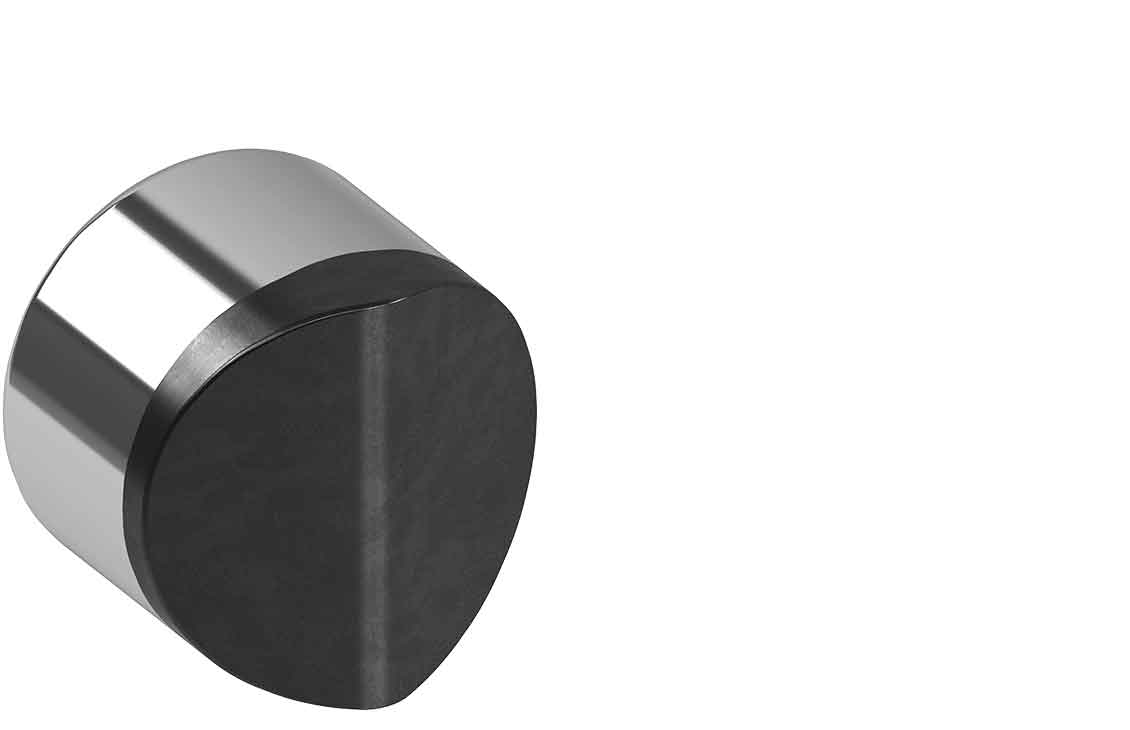

Axe™

Ridged diamond element

- For hard and brittle formations.

- The industry's most record-setting 3D cutting element.

Strata™

Concave diamond cutting element

- For medium-strength formations.

- Improves cutting efficiency as thicker diamond table resists impact damage.

Hyper™

Hyperbolic diamond cutting element

- For soft and plastic formations.

- Distinctive hyperbolic-shaped cutter that cuts 20% deeper into rock.

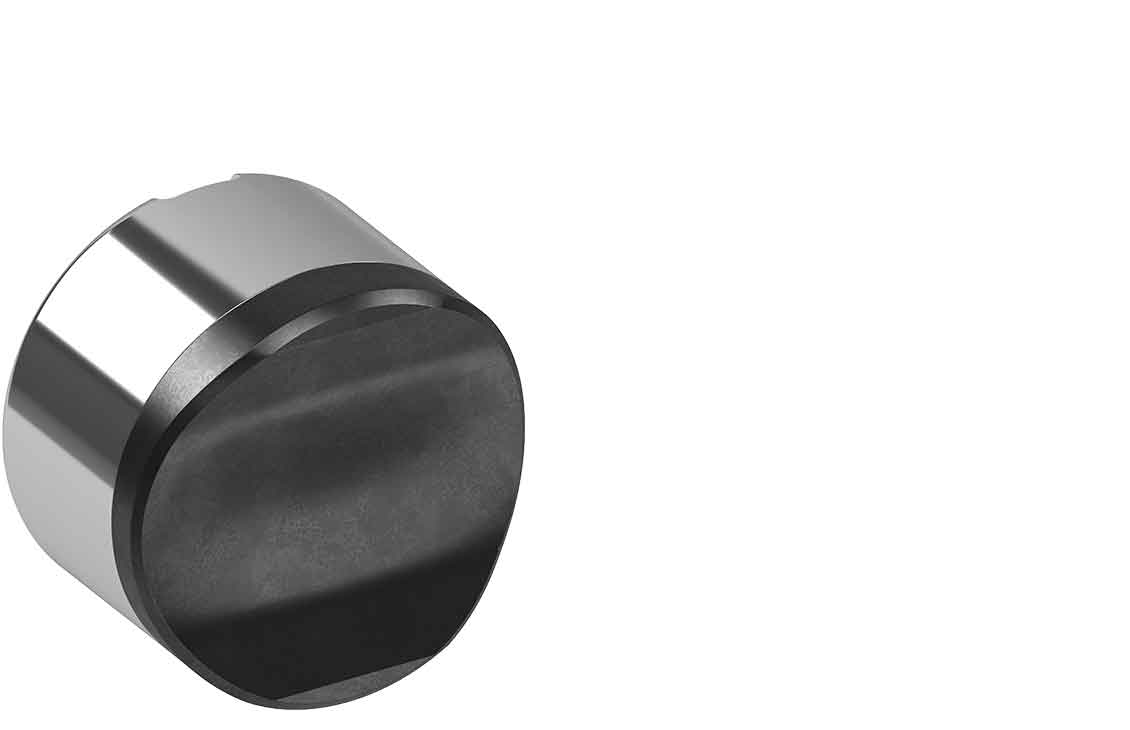

FireStorm™

Wear-resistant high-impact PDC cutter technology

- For all formations.

- Delivers superior wear resistance while increasing impact resistance by an average of 20%.

Talk with an expert