Physics-Informed AI

Simulation-quality insight with the speed and flexibility of AI

Physics-informed AI is a breakthrough hybrid model building technique, that fuses physics-based simulation and process data.

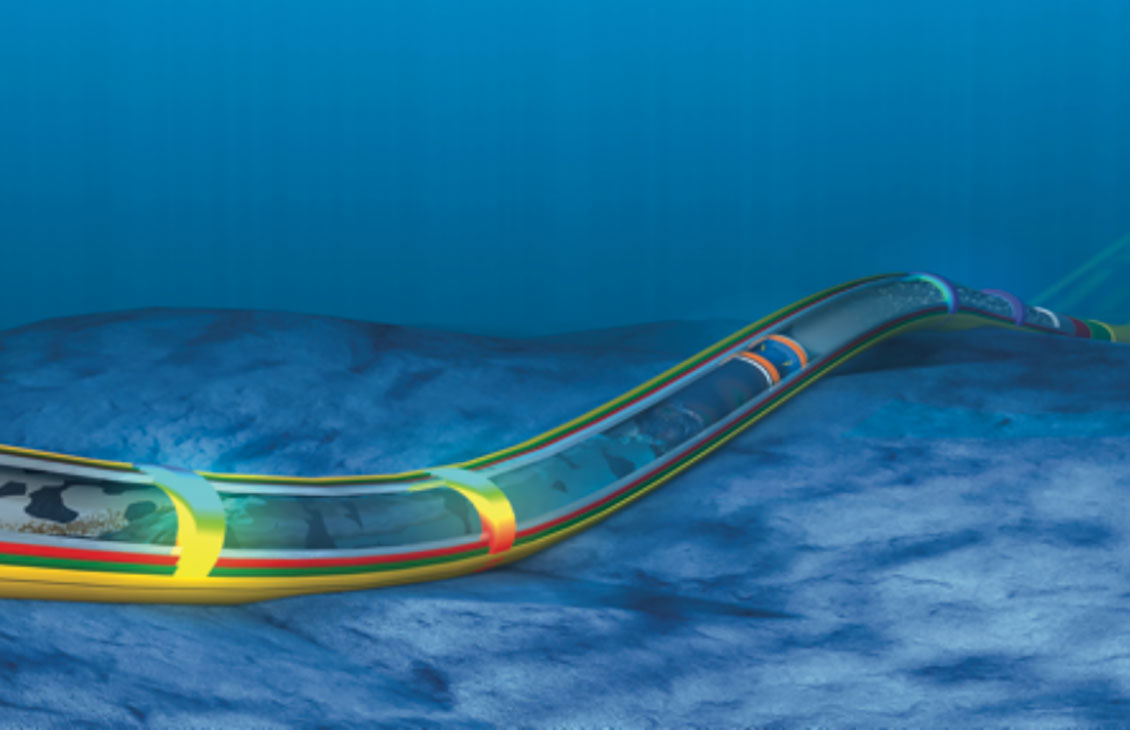

The Olga™ dynamic multiphase flow simulator models transient flow (time-dependent behaviors) to maximize production potential. Transient modeling is an essential component for feasibility studies and field development design. Dynamic simulation is essential in deep water and is used extensively in both offshore and onshore developments to investigate transient behavior in pipelines and wellbores. Transient simulation with the Olga simulator provides an added dimension to steady-state analysis by predicting system dynamics, such as time-varying changes in flow rates, fluid compositions, temperature, solids deposition, and operational changes.

From wellbore dynamics for any well completion to pipeline systems with various types of process equipment, the Olga simulator provides an accurate prediction of key operational conditions involving transient flow.

Verification and Improvement Project (OVIP), which has collected the world’s largest database of lab and field data. This data has been used to validate and adapt the multiphase flow models. Results are continuously implemented in the Olga simulator, improving the core technology to better match the realities of operations.

Additionally, the Robust, Enhanced and Accurate CO2 Handling (REACH) and Transport and Integrated Domain Extension (Olga CO2 TIDE) projects are cosponsored by major oil companies. These projects address challenges in cost-effective development and safe operation of long-distance gas-condensate and oil well stream transport.

The webinar series targets users of the Olga dynamic multiphase flow simulator and the Pipesim steady-state multiphase flow simulator and associated consumers of the simulation results with the intent to share knowledge of the capabilities and best practice use of these powerful and versatile simulators.

Equinor has, through a technical qualification study, selected SLB for delivering a novel leak detection and virtual flow metering solution for the multiphase production network in Johan Sverdrup Phase II. The solution is based on Olga Online™ production management system.

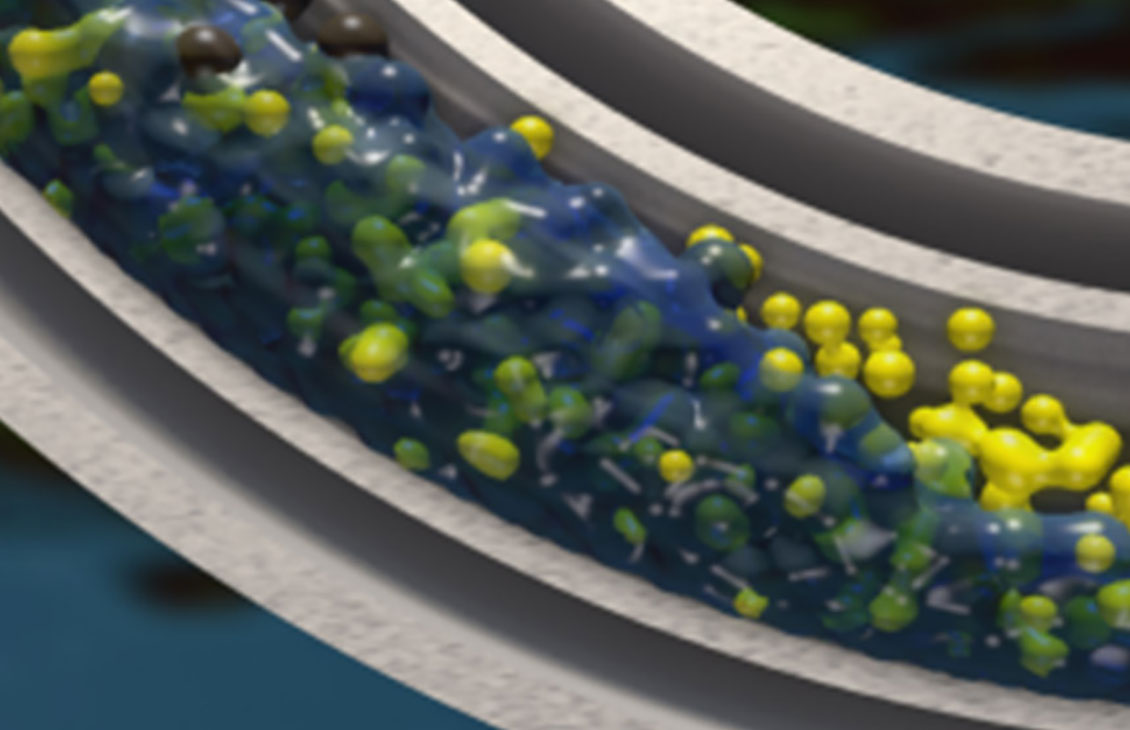

Successful production system design and operations requires a detailed understanding of multiphase flow behavior. Flow modeling and simulation provides valuable insights into flow behavior, including the physics describing flow through the entire production systems, from reservoir pore to process facility.

The Olga simulator models time-dependent behaviors, or transient flow, to maximize production potential. Transient modeling is an essential component for feasibility studies and field development design. Dynamic simulation is essential in deepwater and is used extensively in both offshore and onshore developments to investigate transient behavior in pipelines and wellbores.

Recent developments through joint-industry projects in CO2 flow modeling enable reliable design and operations of the CO2 transportation and injection systems.

Flexibility in PVT modeling engines provides engineers with an option to select the technologies and equations of state of their preference.

Olga simulator’s architecture allows simulations to be run on the cloud to maximize CPU capacity when launching multiple simulations for sensitivity analysis.

The Olga dynamic multiphase flow simulator is a comprehensive transient simulator for system design and production operations, that has been the industry standard tool for dynamic multiphase flow simulation for over four decades. It can be used in the energy industry for hydrocarbon flow predictions but also for CO2 based flows, steam/water, nitrogen and other types of fluids. In addition to the principal flow model, the Olga simulator incorporates various other models essential for accurately simulating transient flow from reservoirs to processing units.

These models enable the calculation of pressure, temperature, flow regimes, liquid holdup, slug characteristics, and tracking of individual components. With this capability, users can design and operate production gathering and distribution systems with confidence.

The Olga simulator features a best-in-class three-layer flow model that handles gas, oil, and water. It adeptly manages single-phase to multiphase flows, including gas, oil, water, and solid phases, with different phases dispersed across various layers. The simulator solves a single energy equation and excels in handling both slow and fast transients. Additionally, the Olga simulator includes both a one-dimensional flow model (Olga simulator friction factor [FF]) and a three-dimensional flow model (HD model).

Typical flow assurance applications for transient analysis:

Due to lower maintainability and higher costs in offshore environments, all the design work and operational procedures require much more attention to detail. Verifying and developing plans for flow assurance activities in offshore, requires many simulations to be run, with sensitivity analysis and parametric studies. For onshore facilities and wells the scenarios are the same but simulations are run less often.

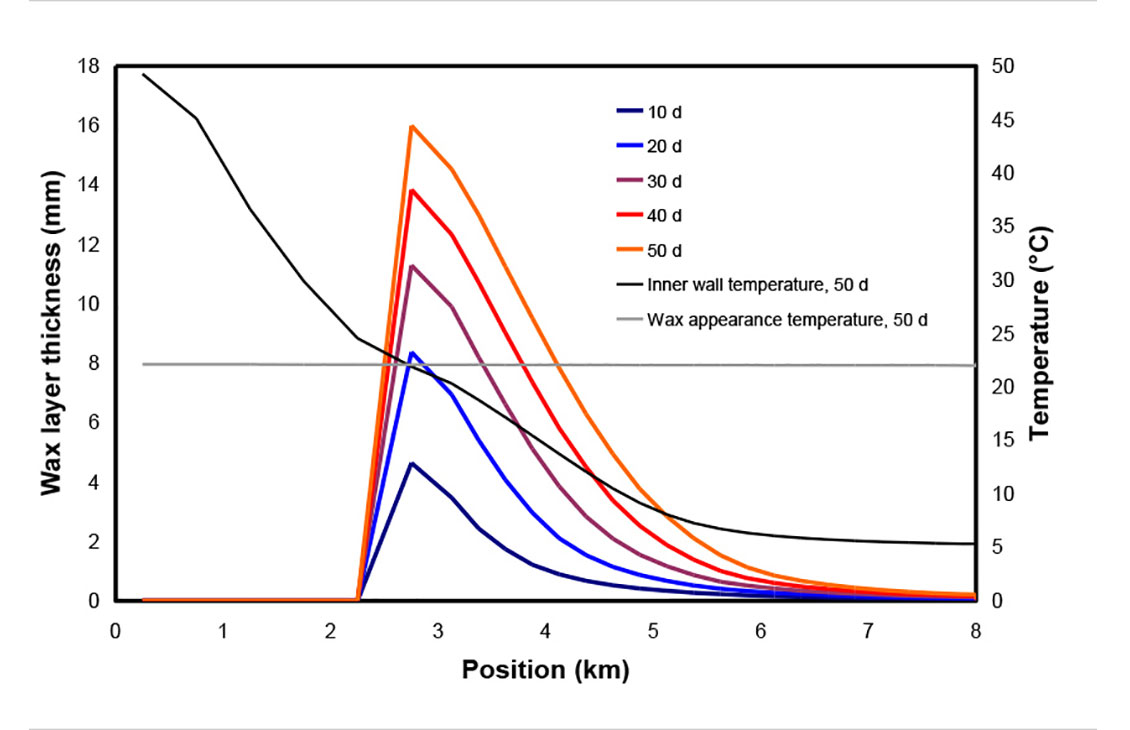

Yes, it does. The Olga simulator is particularly well suited for sophisticated thermal simulations. It is one-dimensional (calculates along the pipe axis), any two and three-dimensional effects must be modeled explicitly. The basic Olga simulator thermal model calculates the inner wall heat transfer coefficient. The built-in correlations are valid for natural and forced convection and for the transition between them. Flow pattern is accounted for. The user may specify pipe walls with material properties, including emissivity to account for radiation, and must give the ambient properties, that is, temperature and heat transfer coefficient. Based on this, the fluid temperature is calculated.

The Olga simulator can account for complex interactions between flow paths and surrounding solids, using a two-dimensional temperature field around flow paths. This is useful when modeling, for example, buried pipelines or complex risers.

For pipelines:

For wells:

Olga Online™ production management system works in real-time and is designed with the needs of the modern production operation in mind. Offering all you need for multiphase flow assurance, powered by the Olga simulator.

There are several training options:

Comprehensive training catalog can be accessed on the SLB NExT Training website: NExTtraining/olga

Additional training for customer specific workflows and operations can be customized upon request.

Throughout the year, SLB organizes Olga simulator focused virtual webinars for global audiences. See the schedule on https://www.slb.com/products-and-services/delivering-digital-at-scale/production/flow-assurance-webinar-series. There are also scheduled User Group Meetings (UGMs) held annually in different parts of the world.

Carbon capture

The Olga simulator is one of the most effective simulators for CO2 transport and injection available today. Flow assurance considerations and accurate simulation of CO2 transport and injection are essential elements for successful CCS design and operations. Transient modeling is key to understanding complexity and uncertainties associated with CO2 transport and injection.

The Olga simulator has been used for simulation of CO2 systems for more than 15 years. It started with the single component functionality to model pure CO2 back in 2009. Since then, we have validated Olga simulator modeling capabilities against high quality data from a flow loop built at the Institute for Energy Technology (IFE) in Norway.

With the pressure-enthalpy flash formulation made available in Olga 2017, we can now model CO2 containing other components with higher accuracy and robustness.

We have continuous focus on both validation and development of new capabilities. The R&D project "CO2 FACT” was concluded before “Olga CO2 REACH” began in June 2022. “Olga CO2 REACH” has been ongoing since 2022, and one of the outcomes of this R&D is a new solver, called “Olga New Solver (CCS)”, which became commercially available in Olga 2025.1 version released in December 2024.

Hydrogen

Simulations play an important role in the design and operation of hydrogen systems.

With the Olga simulator you can:

Geothermal

The Olga simulator can accurately model geothermal, using the single component option, if pure water is used as a working fluid. Flow assurance considerations and accurate flow simulations give key insights for the optimal design and operation of geothermal systems.

The Olga simulator has unique capabilities to simulate dynamic operational scenarios.

NExT offers a comprehensive training program to support users of the SLB software, plugins, and other software products.

New insights can be gained through the utilization of the secure, cloud-based environment as increased accessibility and flexibility to more science in the GPM software is automatically and instantly at your fingertips.

Explore

Ensure fluid flow to maintain production—from pore to process.

Developed to provide consistent and accurate simulation results for multiphase CO2 transportation.

Design mitigation strategies and identify when solids form.

Well production optimization requires understanding of transients.