Produce better-quality drilling programs in minutes.

Integration unleashed: transforming well construction

已发表: 06/13/2025

Integration unleashed: transforming well construction

已发表: 06/13/2025

Integration is a crucial concept in the field of well construction, but what does it truly mean? We sat down with Gaelle Lecomte, head of products for drilling operations and performance, and Kevin Hermansen, head of products for drilling planning, to discuss how integration impacts their work and the broader industry.

What does integration mean to you; can you give some examples from either work or home life?

Gaelle: For me, when I first think of integration, my immediate thought is about the integrated well construction team in SLB. I work on many topics and projects with them, which is one way that we can use integration to bring value to our customers and ultimately to SLB. Our collaboration on large scale projects allows us to learn more about our customers' workflows, test new ideas, and improve our processes.

More broadly, I think integration is about closing the loop between planning and operations and linking back to subsurface. It's about ensuring that information and knowledge flow seamlessly from one part of the organization to another, without the traditional silos that exist in many workflows and companies.

Kevin: I felt exactly like Gaelle. I thought of integrated well construction straight away and then I was thinking more of what we do in our digital products, and what I've been working on for 10 years with DrillPlan™ coherent well planning and engineering solutions.

Integration for me is almost the same as collaboration in a way, and that’s what DrillPlan solutions was built on. Interdisciplinary collaboration and integration.

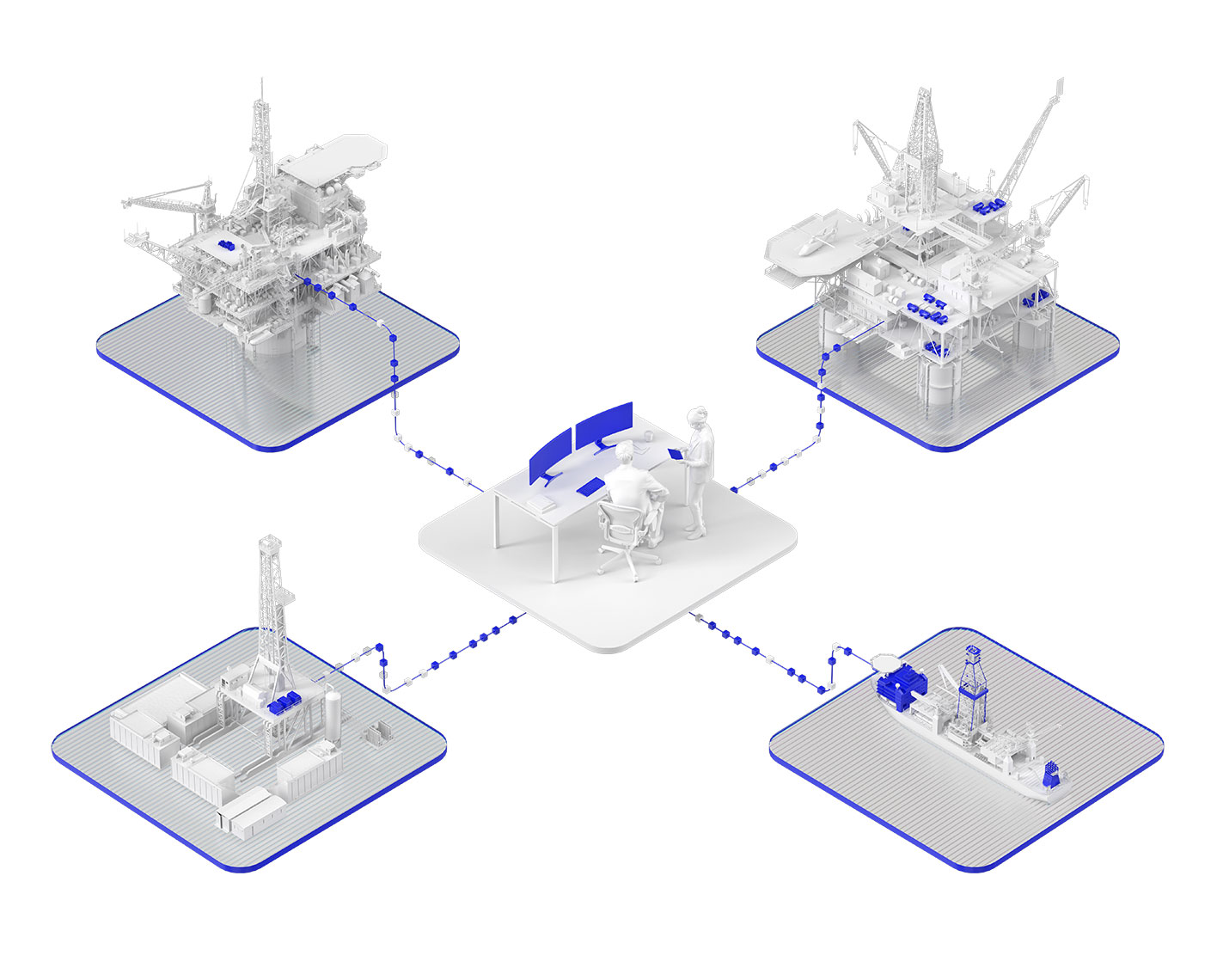

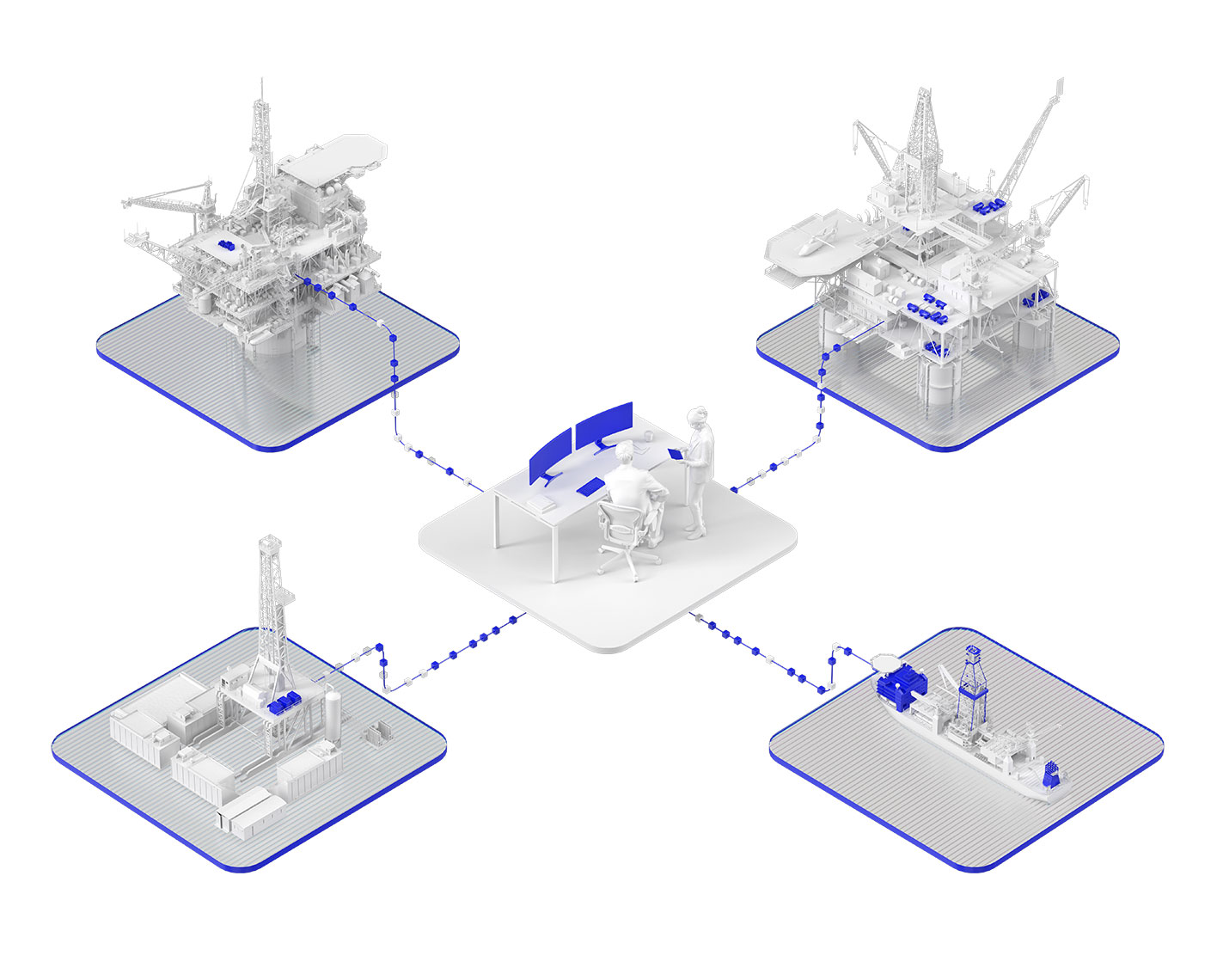

I see it as connecting four big pieces—the subsurface, drilling, production, and completions. So, everything is connected, integrated, and talking to each other seamlessly across the entire well lifecycle.

Another key aspect, which can sometimes be overlooked, is that when we provide these digital products, they help to remove silos and barriers, not just between domains but I would say also between generations. Younger engineers, senior engineers, subject matter experts (SMEs), managers, and contractors can all be integrated into the same platform, giving them access to the same tools and data and enabling proper communication. This is how we can create a fully connected infinity loop across the lifecycle of a well, which I believe is a great representation of what true integration means.

Have you seen integration in action? Can you give any examples related to the digital drilling portfolio?

Gaelle: Integration is a key focus for us. Back in October, I organized a workshop that brought together a significant part of my team. This workshop aimed to further enhance integration within our large portfolio of solutions.

Within the digital drilling operations team, on one hand we have ”town” operations with full access to the cloud, enabling us to run sophisticated engines and focus more on analyzing and understanding the results. On the other hand, rig operations mostly operate at the edge with fast loops, requiring low latency and quick results.

Trying to find ways we can better integrate these two parts and enhance our offerings is a very important part of how I work every day. We aim to fully leverage the learnings and domain knowledge from the town at the rig and vice versa. For instance, we have a project focused on dynamically modifying tripping envelope limits at the rig site, using heavy computation from the town. This is just one specific example, but more broadly, we strive to leverage each area’s strengths to achieve even greater performance.

Integration is not about everyone doing the same thing but about improving communication and collaboration, so we work better together.

So, I think it's fair to say for both of you that you see two different clear aspects. There's integration in the way we work, both as SLB, and with our customers and peer organizations. And then there's the integration that exists within our digital solutions, through joint use of the same engines to ensure consistent result and to transfer data between applications.

Gaelle: Openness is also a crucial piece of the puzzle. I was just speaking with a customer who was looking for an end-to-end solution. Integrating different workflows, whether from planning, subsurface, data management, or drilling, is essential for this. As SLB, we have a strong horizontal integration story today, and there's still room to grow. This is a key differentiator for us. However, it's important to acknowledge that we still face friction, even in the digital world, in how we integrate and interface with different touchpoints in end-to-end workflows, so that we can continue to innovate and develop ever-deeper levels of integration.

Kevin: I also have a compelling story to share in this area. During a deployment exercise with a customer, we implemented a remarkably simple yet transformative rule that became a “Eureka” moment for the team.

We were part of a project that involved many suppliers, and we were using DrillPlan solutions. Our users often found themselves acting more like project managers than engineers, managing communication between various service providers.

So, the rule introduced was straightforward: no emails, no SMS, no letters, no messaging, no file exchanges—literally nothing outside the digital tool. This rule was a game changer. It led to vendors working together seamlessly, without the stress of remembering whether they had sent the latest cement program or updated trajectory data. It eliminated the anxiety of wondering if everyone had been updated on safety-critical design elements and last-minute changes, as everything was in the same tool.

You could see the real-time collaboration and integration within the digital tool. Everyone had access to the information at any time. Now, I recommend this method to other customers: ignore emails and text messages and consider any information outside the platform unread. I’ve found that this approach can create a surprisingly dramatic change in the working lives of those using our tools.

Could you give a more detailed description of how the integration works within the software portfolio and the value it brings to customers?

Kevin: When it comes to integrating across domains and products, it's not just about, for instance, connecting subsurface and drilling but liberating their work. For example, subsurface knowledge like 3D grids or geomechanical earth models are now available in the cloud. Drilling engineers get live updates on pore pressures, fracture pressures, and formation tops, which are critical for drilling engineering. This real-time data means drillers don't have to disturb those working in subsurface for new exports, improving collaboration despite less direct interaction.

Gaelle: They can collaborate better on what matters, like well and domain expertise, rather than exchanging files and transactional tasks. This is a strong differentiator because it connects planning and operations, enabling smooth collaboration between traditionally separate worlds like drilling and subsurface.

Kevin: And you have the same goal in DrillOps predictive analytics, connecting Geomechanics Insights with operations, making them independent of a geologist in the office. You can continue working without waiting, even when you need to deviate from the plan.

Gaelle: You're leveraging domain expertise and focusing on what matters, breaking silos and focusing on the technical background and thinking. Instead of manual transactional tasks like writing emails and ensuring distribution lists. It's meaningful collaboration rather than transactional collaboration.

Kevin: You also have it on a smaller scale. Like connecting to the Wellbarrier™ well integrity life cycle solution, you have one button in DrillPlan solutions to automatically generate your well barrier, which removes a huge amount of work and potential for human error. Even seemingly small examples like this can have a huge impact on how we spend our days and on performance overall.

What do you see as the North Star to aim for in terms of integration?

Gaelle: The phrase may be overused, but I would say that it’s still all about closing the loop. Today we have good connections between applications but ultimately, I see the most promise in having a layer on top of that, a kind of virtual agent that can tap in to all the knowledge that we have at once. It would mean being able to completely leverage the power of integration and almost unify the entire well life cycle into one connected workflow.

Kevin: To me the North Star for integration should be the pursuit of innovation that transcends perceived boundaries and limitations. Today, the true barriers to progress are often not technical but organizational and perceptual. We typically see resistance in expressions of attitudes like, "We've never done this before," or "We've always done it this way."

Recently, we witnessed a remarkable example of what can be achieved when customers fully embrace the potential of integration. One customer chose to place their trust in the technology and the robust science that underpins it—science supported by over 30 years of rigorous research and real-world experience. Their commitment resulted in not only their fastest ever, but also safer drilling operations, while adhering to the plan. This is just one example among many of how open-mindedness and trust in innovation can lead to groundbreaking advancements and set new standards for the industry.

Gaelle Lecomte

Head of products for drilling operations and performance

Kevin Hermansen

Head of products for drilling planning