Shuttle

Rigless electric submersible pumps

Cost and efficiency improvements

Rigless ESP replacement saves time and expenses, ensuring minimal production delays and operational cost reductions.

Enhanced safety and sustainability

Simplified operations reduce personnel exposure and cut CO₂ emissions with efficient single-trip rigless replacement methods.

Optimized performance and reliability

Prevents ESP failure, enhancing well performance and ensuring reliable, energy-efficient production with durable system features.

Retrieve and redeploy ESPs without a rig or hoist

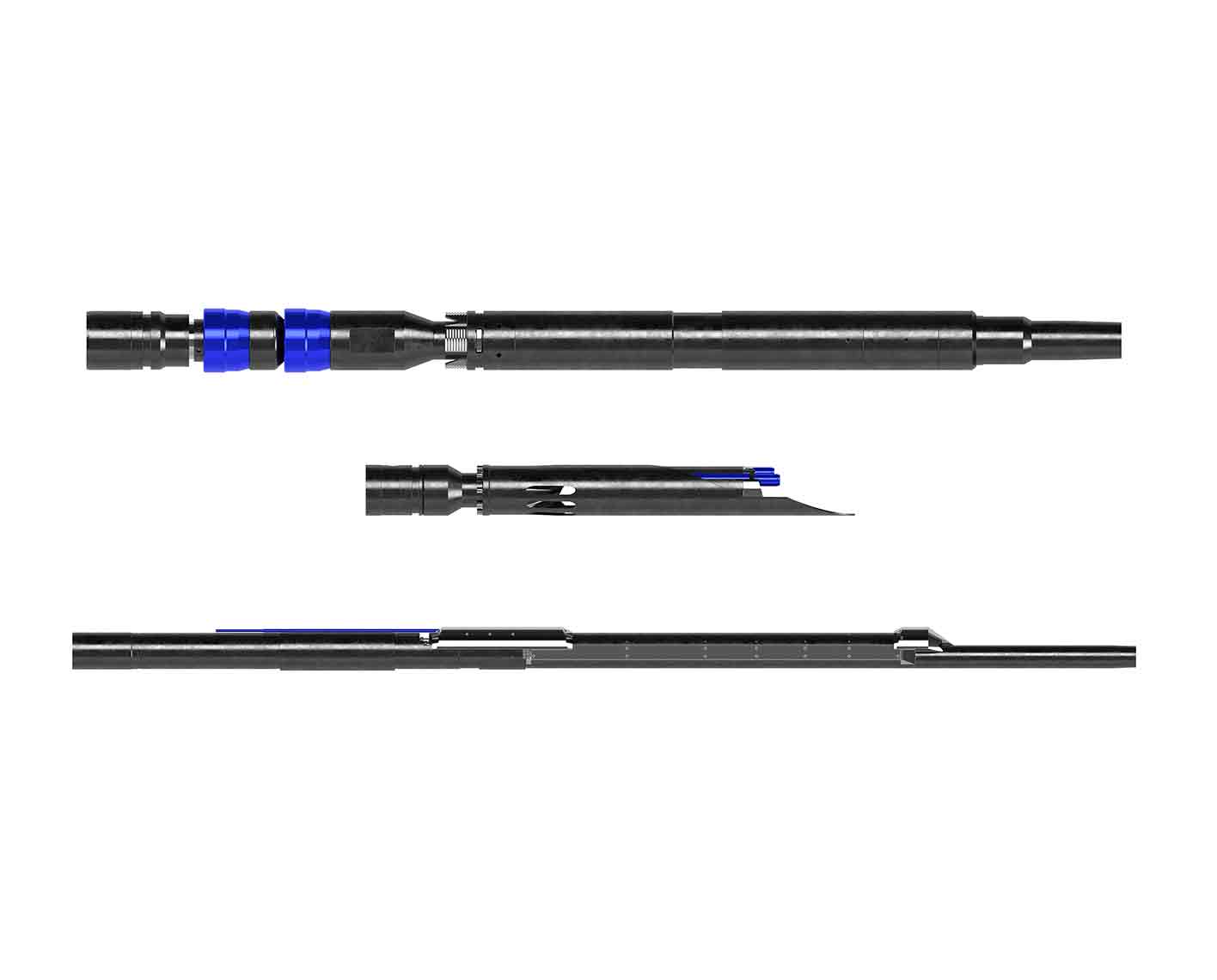

Retrieve and redeploy any standard electric submersible pump (ESP) system without the expense of a rig or hoist by using the unique plug-and-play design of the Shuttle™ rigless ESP replacement system. The Shuttle ESP system features two main assemblies: a retrievable ESP component and a semipermanent completion that includes a docking station that enables connection of a retrievable ESP motor to the surface power supply system. The use of wet-mate connector technology ensures reliable downhole electrical connection under pressure, temperature, and the presence of a wide range of downhole fluids.

- 7-in or larger casing ESP wells

- Offshore and deepwater ESP wells

- Onshore ESP wells

- Conventional ESP wells

- Water source and water injection ESP applications, including in-well reinjection

- Wells with casing integrity issues

Minimize deferred production

This rigless ESP replacement system minimizes deferred production, eliminates disruption to operations, and reduces HSE exposure and risk. Additional benefits include the following:

- Improve cash flow—Minimize deferred production to improve opex

- Enhance economics—Improve cash flow and asset value by reducing deferred production and opex

- Optimize ESP well performance—account for changing well performance by replacing suboptimal ESP prior to failure, thereby improving production and reducing energy consumption

- Simplify ESP replacement operations—Deploy convenient rigless replacement using braided line, e-line, CT, or sucker rods

- Boost sustainability—Reduce related CO2-related emissions by employing rigless single-trip replacement

- Protect ESP assembly during replacement by improving power deliver reliability through annulus isolation, automatic connector alignment, and protecting against thermal expansion and contraction

- Improve wellsite safety—Execute simplified, shorter interventions that reduce the number of personnel and their HSE exposure

- Support preferred ESP systems—Full compatibility with ESPs and ESPCPs with an induction motor (IM) or permanent magnet motor (PMM).

ESP replacement within hours, not days

During initial installation, the docking station is typically run to a shallow depth on a large bore production tubing capable of accommodating the ESP inside. The retrievable ESP assembly, with the motor connector at the bottom, is then assembled, lowered inside the tubing, and simply landed in the docking station, with no further manipulations downhole. The complete Shuttle ESP system is then lowered to pump setting depth in the identical manner to a standard ESP system, with the power delivery system deployed on the outside of the production tubing.

When ESP replacement is required, the whole retrievable ESP assembly can be quickly unplugged from the docking station and retrieved within a few hours in a single trip. A GS pulling tool—lowered on wireline, coiled tubing, or sucker rods—is latched on top of the ESP string, which is then simply retrieved through the production tubing and a surface Xmas tree, which remains in place during the replacement sequence. After service or replacement, a new ESP string is then redeployed inside production tubing using the same method—eliminating reservoir and production uncertainties, and the economic impact of rig availability and cost.

Shuttle System Wins Industry Award for Engineering Innovation

E&P magazine honored the Shuttle rigless ESP replacement system with a 2017 Special Meritorious Awards for Engineering Innovation, after being judged by an independent team of experts. The system reduces operating costs and eliminates disruptions to operations by enabling any standard ESP assembly to be retrieved and redeployed without a rig—using wireline, coiled tubing, or sucker rods.

Read article