Frac packer

High-pressure expandable steel packer for openhole multistage stimulation

Openhole hydraulic fracturing

Achieve on-demand cost-efficient sealing even in irregular boreholes

SLB frac packers seal in any hole shape and condition, including oval, out-of-gauge, and irregular boreholes, preventing fluid migration in the annulus and ensuring that the fracture initiates in the correct place. They also seal reliably through thermal cycling and temperature fluctuations. Pressure on the formation is controlled to provide a good seal without creating a high-stress point.

Rapid installation, on-demand expansion, and immediate sealing eliminate waiting, which reduces time and costs. Absence of special well fluid requirements for expansion further lowers cost. The packer is run in on a casing string; it maintains casing rating by avoiding extra connections and casing ID reduction. Its robust construction eliminates any risk of premature setting when working the string to pass through doglegs and tight spots, minimizing NPT.

- Proprietary expandable steel technology

- Rapid installation and simplified setting process

- Compatibility with all standard casings

- Burst and collapse ratings equivalent to casing ratings

- Significantly more robust than rubber to withstand reciprocation and rotation

- Built-in safety feature if expanded in front of a washout

How is the packer set?

Activation procedure

The frac packers are made up to a casing string that is run into the open hole. Rotation is possible

while running in, and full casing characteristics are maintained. Once in position, the lower end of the

casing string is sealed and the internal pressure increased by pumping from surface.

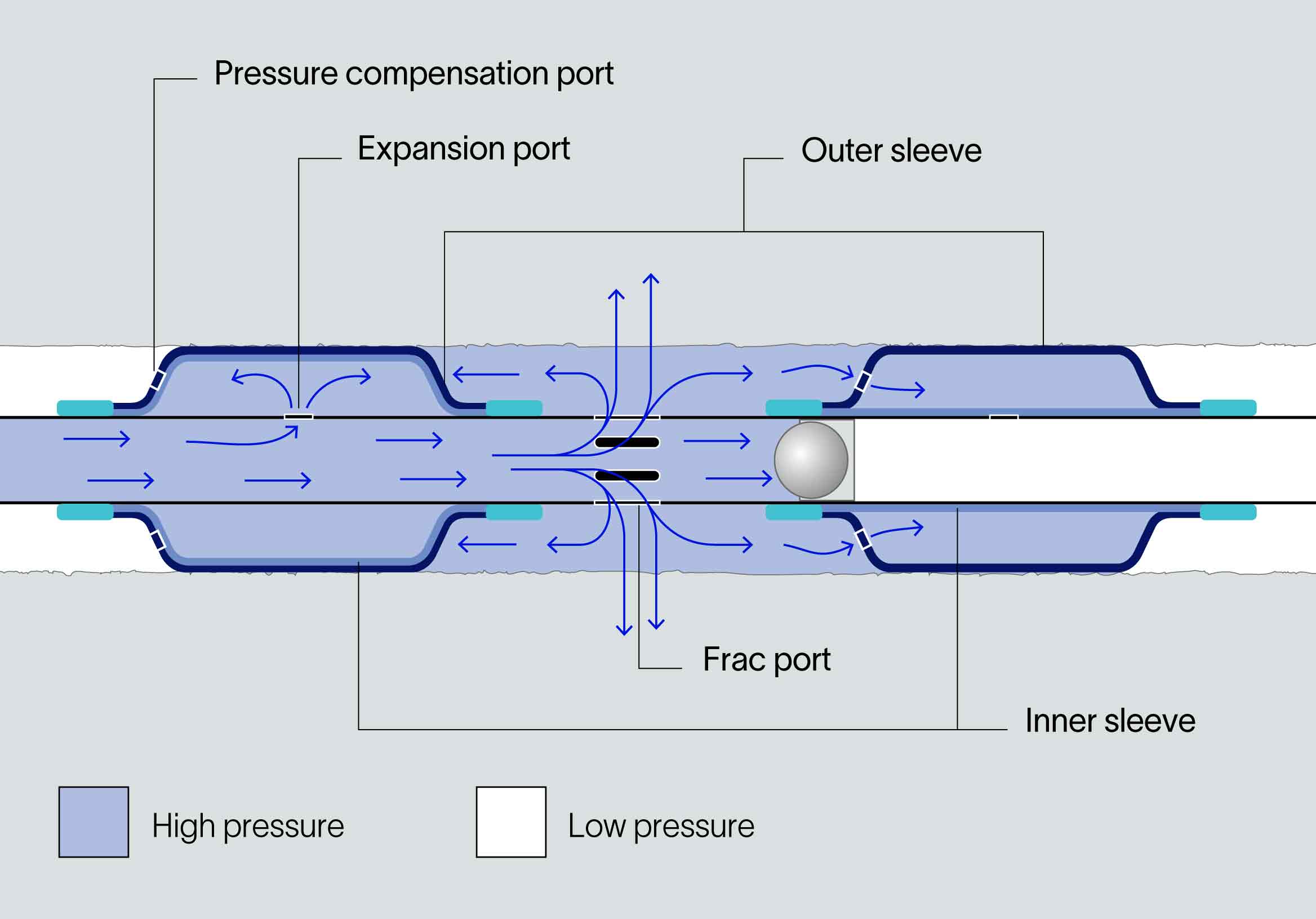

This pressure is transmitted through the expansion port to the packer’s integral stainless steel sleeve. The sleeve expands out into the annulus between the casing and borehole, conforming to the shape of the wellbore and isolating the annulus below the packer from the annulus above.

The patented pressure-balanced double sleeve can maintain a seal despite thermal cycling and varying differential pressures in the annulus. Expansion of the sleeve also centralizes the casing.

Expansion port with valve

The expansion port features a valve system integrated within the casing thickness; this valve acts as

a safety feature. If the packer is expanded in front of a severe washout, the valve closes, preventing

fluid loss.

Reliable sealing

Our high-pressure frac packers achieve sealing with a thin layer of bonded elastomer (HNBR).

Dynamic seals can be mounted between steel rings to enhance sealing capacity and increase the

temperature range. The end fittings protect the expandable sleeve while running in the well.