MaxPull

High-pull wireline conveyance system

Expanding wireline conveyance to all well profiles and environments while reducing risk

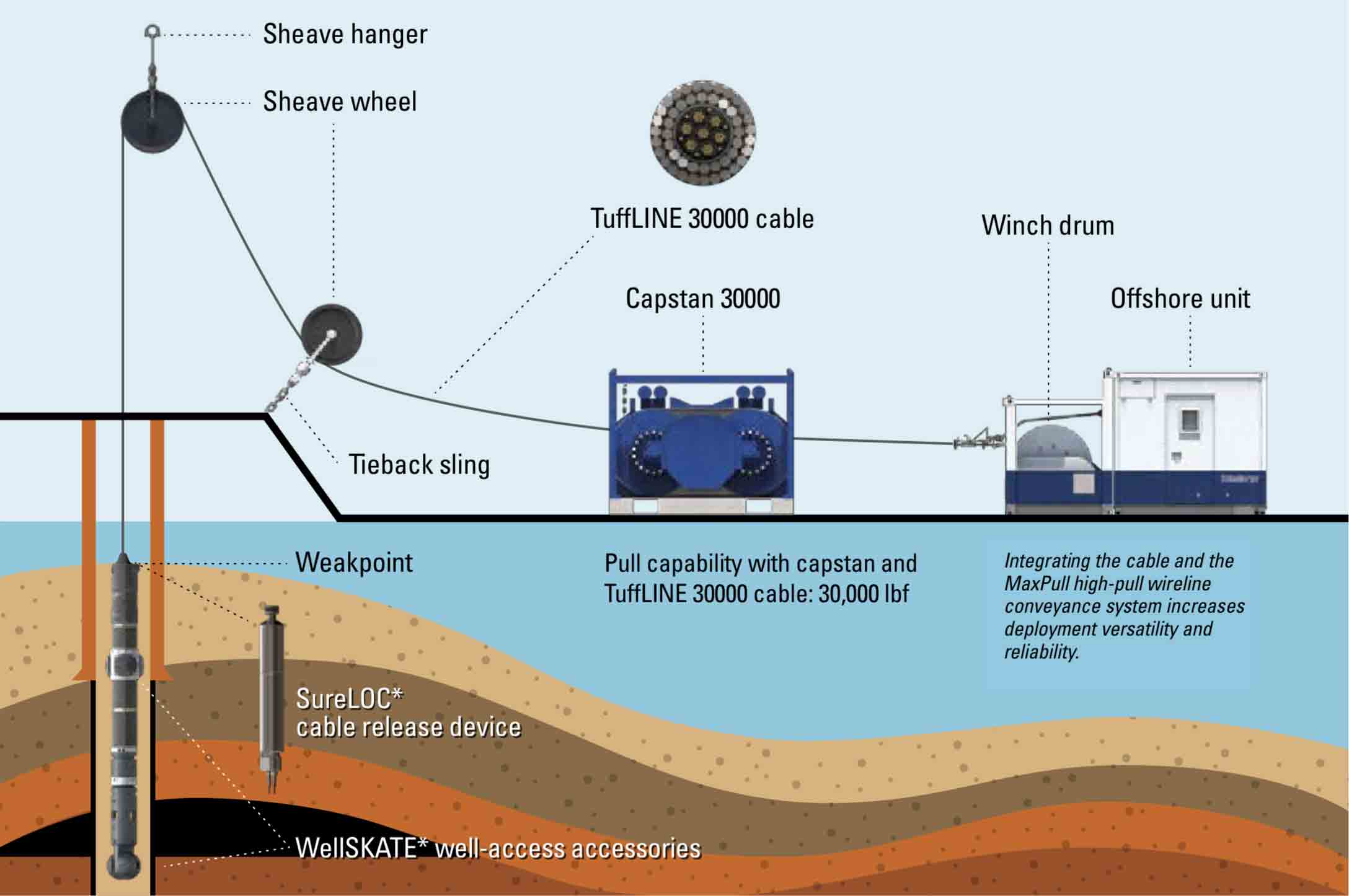

The MaxPull system reengineers wireline conveyance to fully integrate all system components—from the surface equipment to the cable and downhole accessories—providing complete conveyance for every possible well profile and well environment. Deployment on wireline, instead of defaulting to conventional drillpipe or coiled tubing conveyance significantly reduces risk, especially for high-pull operations in ultradeepwater, extended-reach, and complex trajectory wells.

The latest MaxPull 30000 system enables all phases of exploration, development, and production. By giving you complete wireline data acquisition, the MaxPull 30000 system lets you fully and accurately characterize reservoirs while saving millions of dollars through efficiency, speed, and sticking avoidance.

Customizing the MaxPull high-pull system

The MaxPull system is customizable for both high-tension and routine operations by using the advanced Well Conveyance Planner. The planner forecasts logging tensions, provides design recommendations, and determines the associated risk to specify system components:

- TuffLINE 18000, 26000, or 30000 torque-balanced composite cable

- Modular offshore unit without capstan or rated to 30,000 lbf with dual-drum capstan

- WellSKATE low-friction well-access accessories

- SureLOC electronically controlled cable release device and optional multiple inline release devices positioned strategically along the toolstring

- UltraTRAC and UltraTRAC Mono all-terrain wireline tractors.

The result is a completely integrated system that increases wireline conveyance applicability and reliability, while minimizing cost, risk, and tool sticking. Consequently, you can

- log wells deeper than 36,000 ft in the Gulf of Mexico

- tractor hundreds of thousands of feet in horizontal wells in North American unconventional plays

- reduce tool sticking risk in emerging deepwater reservoirs

- eliminate conventional reliance on costly and time-consuming drillpipe conveyance for increasingly complex well environments

- save millions of dollars on maintenance transportation trips needed for conventional high-strength cables deployed in challenging remote exploration wells.