Drilling Geomechanics

Expertise, answers, and insight to maintain wellbore stability and quality

Improve well placement and design

Reduce exposure to drilling hazards

Reduce NPT and well costs

Monitor pore pressure predictions ahead of bit

Our drilling geomechanics services combine prejob offset analysis, earth model building, and remote expert support during operations to manage geomechanics challenges. Designed to address increasingly complex geomechanical environments with uncertain subsurface pressures, stresses, and rock properties, our services help you make the right decisions and maintain a stable wellbore.

Predrill planning

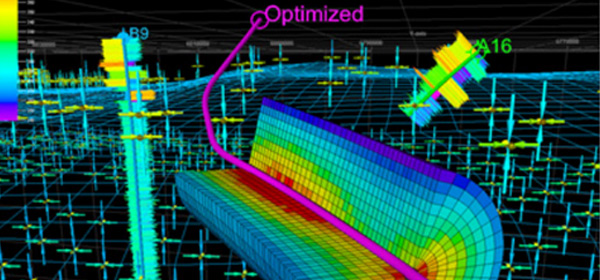

The subsurface mechanical earth model constructed in the predrill phase is used to optimize wellbore stability boundaries for a proposed trajectory. A multidisciplinary team develops a well plan that identifies hazards associated with the trajectory and presents wellbore stability information that can be used by all stakeholders involved in well construction.

Monitoring and predicting

As new datasets become available, the well plan is updated to ensure that it remains current. Changes in the geological sequence or changes to pore pressure and wellbore stability boundaries may necessitate changes to the well plan, such as moving a casing point.

During drilling operations, geomechanics experts analyze all available drilling, petrophysics, mud, seismic, and geological data in real time to visualize current downhole conditions. The real-time information acquired from LWD services, surface data including solids and gas monitoring from wellsite-based surface logging experts, and drilling parameters enable the team to reassess hazards to provide the best information for taking preventive or remedial action.

Geomechanics software

Optimal decision making and accurate assessment of geomechanical risks for your reservoirs and surrounding formations

Visit page