UNIFLAC

Universal fluid-loss additive

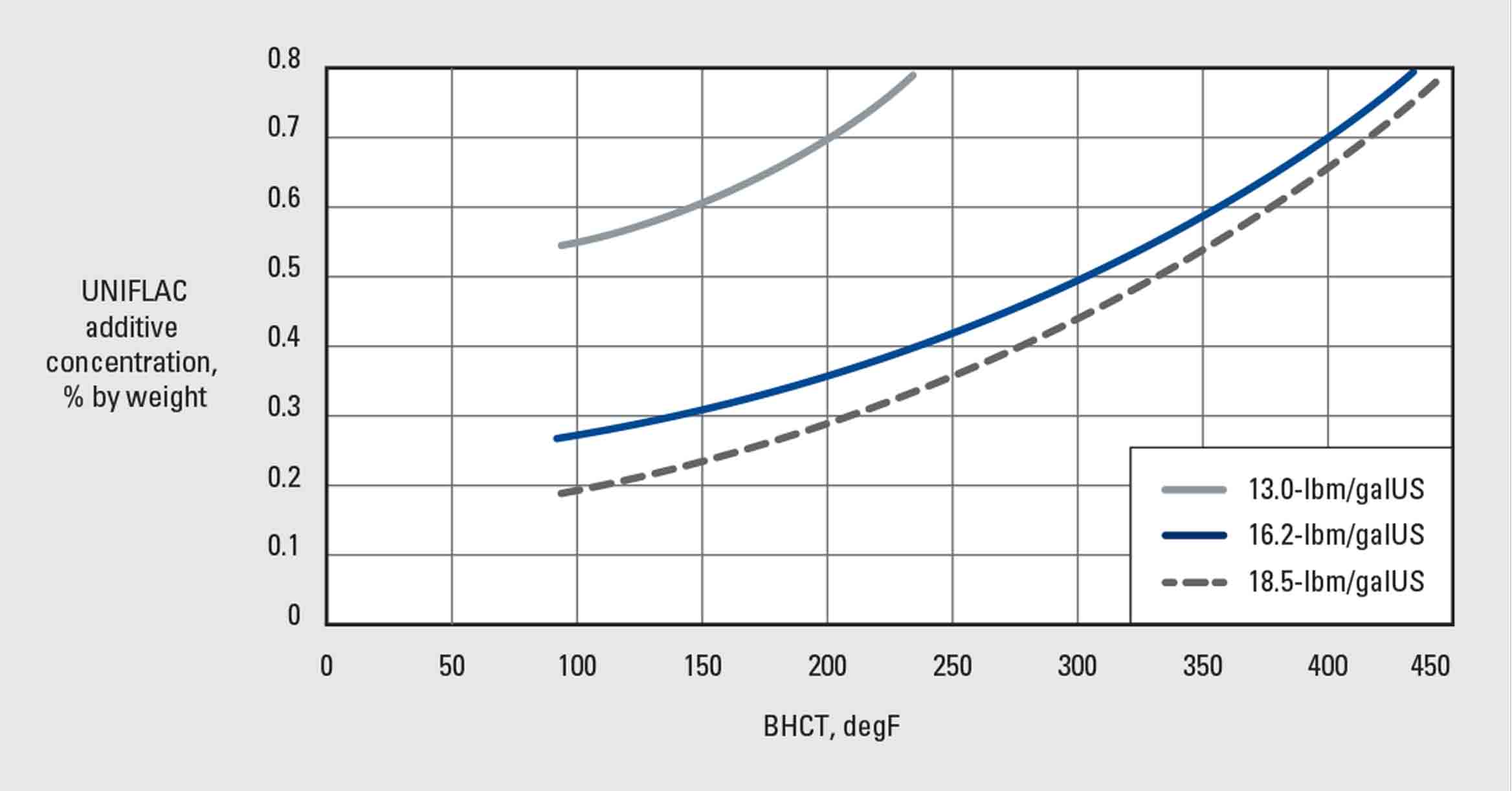

Required UNIFLAC additive concentration to achieve API fluid loss of 50 mL/30 min is easily predictable at different temperatures and slurry densities.

Applications

- Dry-blend in cement using solid UNIFLAC additives D167 and D167A

- Add to mix water using liquid UNIFLAC additives D168 and D168A

- Add fluid-loss and gas migration control

Benefits

- Low cost per barrel of cement

- Savings from less time spent waiting on cement

Features

- Low sensitivity to cement brands and temperature

- Applicability in temperatures from 32 to 400 degF [0 to 204 degC]

- Applicability in densities from 12 to 19.5 lbm/galUS [1.44 to 2.34 kg/L]

- Low concentration requirements

- Excellent slurry rheology

- Compatibility with Schlumberger retarders

- Simplified slurry design

- Simplified logistics—few additives required

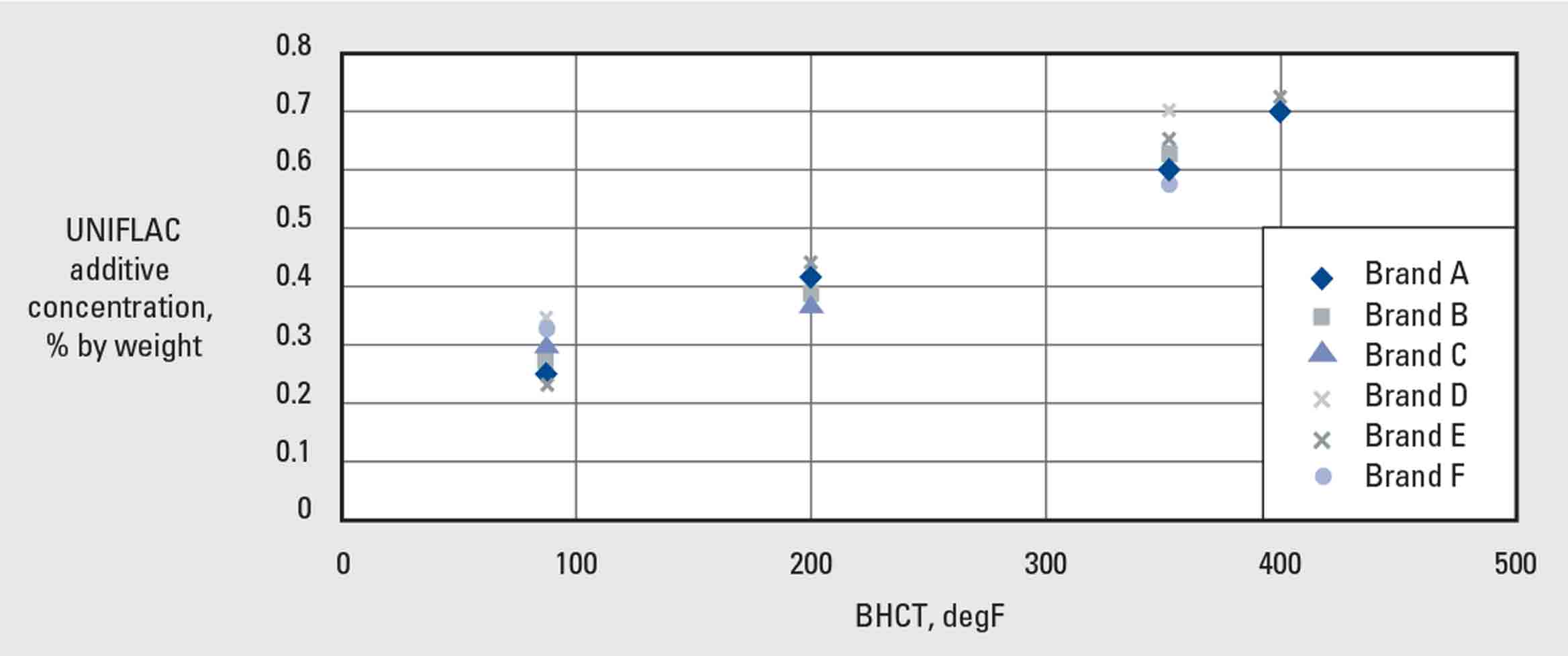

UNIFLAC additive has low sensitivity to various cement brands. The concentration required to achieve a fluid-loss value of 50 mL/30 min remained consistent with different cement brands.

Low sensitivity and synergy

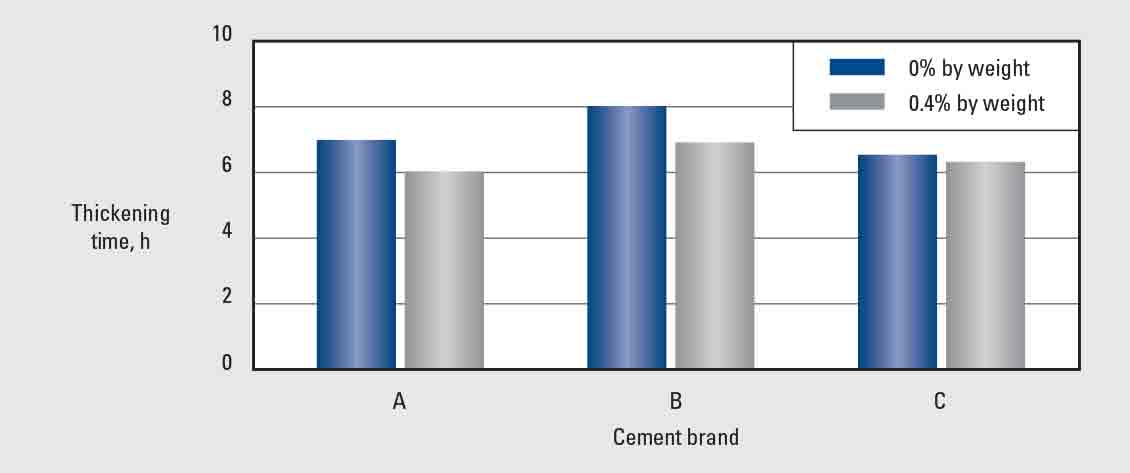

Test results show the very low sensitivity of UNIFLAC additives to small temperature or concentration variations. They are least sensitive to cement brands at bottomhole circulating temperatures (BHCTs) from 32 to 400 degF [0 to 204 degC]. Synergy between Schlumberger retarders and UNIFLAC additives, such as UNISET additive, provides additional operational benefits. Early compressive strength (CS) development reduces waiting-on-cement time. The concentration of retarder required to achieve a desired thickening time is reduced.

UNIFLAC additive has minimal retarding effect at low bottomhole temperatures. These 15.8-Ibm/galUS [1,893 kg/m3] slurries were tested at 70 degF [21 degC].

A lower D161 retarder concentration is required to achieve a desired thickening time with UNIFLAC additive for a similar fluid-loss value of 50 mL/30 min. These Class H slurries were tested at 350 degF [177 degC].