Optimize drilling and cementing with reliable loss control solutions.

Real-time cementing success in deepwater Nigeria well

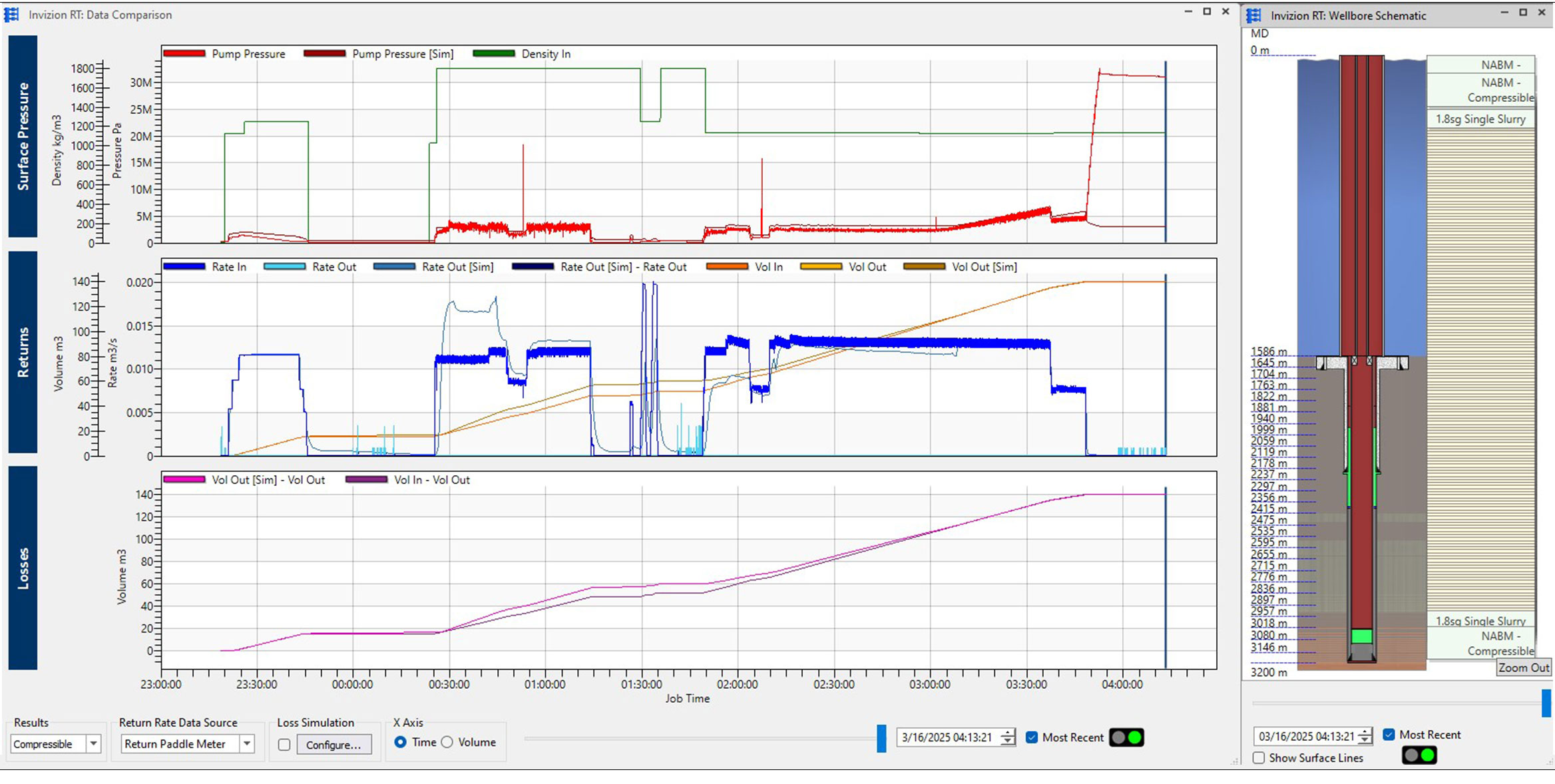

The implementation of the SLB Losseal Microfracture™ lost circulation control treatment and Invizion RT™ real-time well integrity service effectively addressed the cementing challenges faced by TotalEnergies E&P Nigeria Limited in its deepwater operations. The Invizion RT service enabled the real-time monitoring of cement placement and equivalent circulating density (ECD) to ensure accurate top of cement (TOC) and shoe track integrity. The Losseal Microfracture treatment mitigated potential losses, with data confirming the thief zone was above the cemented interval. The job met all objectives, and the operator expressed confidence in using the Invizion RT service for future operations, highlighting its value in enhancing efficiency and reliability in deepwater projects.

TotalEnergies E&P Nigeria Limited, sought to ensure the effective cement placement and maintain shoe track integrity in a deepwater well. The primary goal was to achieve TOC between the R110 reservoir, at 2,344.3 m MD, and the previous casing shoe at 2,198.5 m MD, while mitigating the risk of formation losses across the cemented interval. The project also aimed to leverage real-time monitoring technologies to enhance operational visibility, enable timely decision making, and ensure overall job success.

The application of SLB technologies led to the successful execution of the cementing operation, meeting all defined objectives. The Invizion RT service enabled continuous, real-time monitoring of the cementing process, providing accurate assessment of the TOC and downhole ECD. This capability ensured that the cement was placed precisely between the R110 reservoir and the previous casing shoe, as planned.

Postjob testing confirmed the integrity of the shoe track, addressing a key concern from previous operations where annular pressure buildup and incompetent shoe tracks had been observed. The Losseal Microfracture treatment served as a proactive measure against potential formation losses. Real-time data from the Invizion RT revealed that a thief zone was located above the TOC, enabling the team to manage the risk effectively without compromising the cement job.

The integration of these technologies not only ensured technical success but also enhanced operational confidence. The operator expressed strong satisfaction with the outcome and indicated plans to adopt the Invizion RT service for future intermediate and production casing or liner cementing operations. This project demonstrated the value of real-time monitoring and loss-prevention solutions in improving the reliability and efficiency of deepwater cementing operations.