Achieve unprecedented production and reservoir management.

Electris completion enables use of high-GOR zone for in situ gas lift, minimizing lifting costs

Deploying Electris™ interval control valves (ICVs) with in situ flow rate, water holdup, and PT measurements empowered a Norwegian operator with real-time zonal flow control and enabled optimizing production from multiple zones without costly interventions. The operator was also able to leverage a high-GOR reservoir to provide gas lift, improving energy efficiency and reducing lifting costs while boosting revenue by exporting the approximately 13 million m3/yr [464 MMcf/yr] of lift gas reaching the surface.

In a mature field on the Norwegian continental shelf, water reinjection and gas compression account for up to 75% of total energy consumption. Traditional gas lift poses a challenge due to its high energy demand—which is amplified by lifting unwanted water—and the resulting environmental impact.

Moreover, the field has limited gas processing capacity. Reinjecting some of the processed gas for conventional gas lift reduces revenue from otherwise saleable hydrocarbons.

The operator needed a completion design that would enable leveraging the gas lift potential of a high-GOR reservoir located at the heel of a well. However, traditional gas lift valves with a fixed orifice and passive inflow control devices (ICDs) lack the active regulation required. In addition, hydraulic ICVs with discrete choke positions do not provide the precision necessary to manage uncertainty in the zone’s contribution to production.

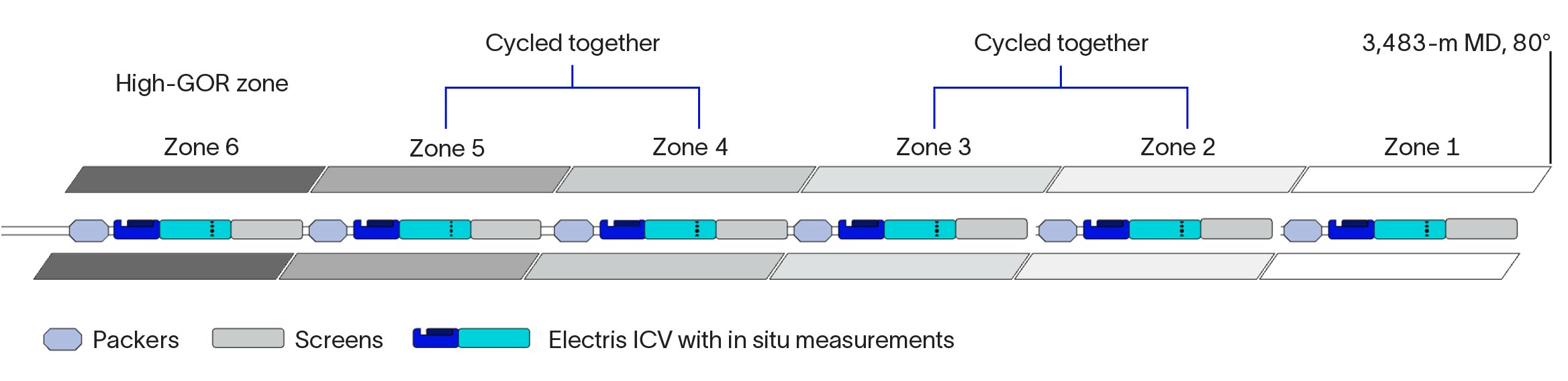

To address these limitations, six Electris ICVs with in situ flow rate, water holdup, and PT measurements were deployed within a third-party gravel-packed completion across multiple reservoir zones, including the high-GOR zone. This advanced system enabled real-time zonal flow monitoring and control, providing the operator’s engineers with actionable insights to optimize performance and enhance recovery.

The Electris ICV's continuous choke provides the ability to fine-tune valve opening via precise micrometric adjustments. In the high-GOR zone at the heel, this capability has empowered the operator to use the zone to provide cost-effective in situ gas lift for maintaining stable oil production. By shutting off production from the toe because of early water breakthrough and sand and by cycling production among the other zones, engineers are managing zonal contributions effectively, in near-real time.

This dynamic production strategy—made possible by electric, high-precision control—has helped maximize oil recovery while minimizing energy consumption by eliminating the need to compress and inject lift gas from surface. The well has outperformed P90 oil production targets and remains on track with base-case expectations—without any need for costly interventions. The lift gas reaching the surface is processed and exported (not reinjected), adding incremental revenue.