Tackle scale, decontaminate naturally occurring radioactive material (NORM), and decommission with efficiency.

Comprehensive barium sulfate scale treatment restores subsurface safety valve operability

The custom-designed treatment addressed the limitations of low reservoir pressure and unique scale characteristics to restore production while minimizing environmental impact.

Producing from a high-permeability 346-m-long [1,135-ft-long] horizontal interval, a North Sea well was completed with sand screens and contains a tubing-retrievable, surface-controlled subsurface safety valve (SCSSV). Production was initially supported by seawater injection, followed by a mixture of seawater and produced water. Since water breakthrough, barium sulfate (BaSO4) scale has presented challenges; it is caused by mixing of the injection water, which has high sulfate content, and formation water containing barium. Water cut is currently >90%.

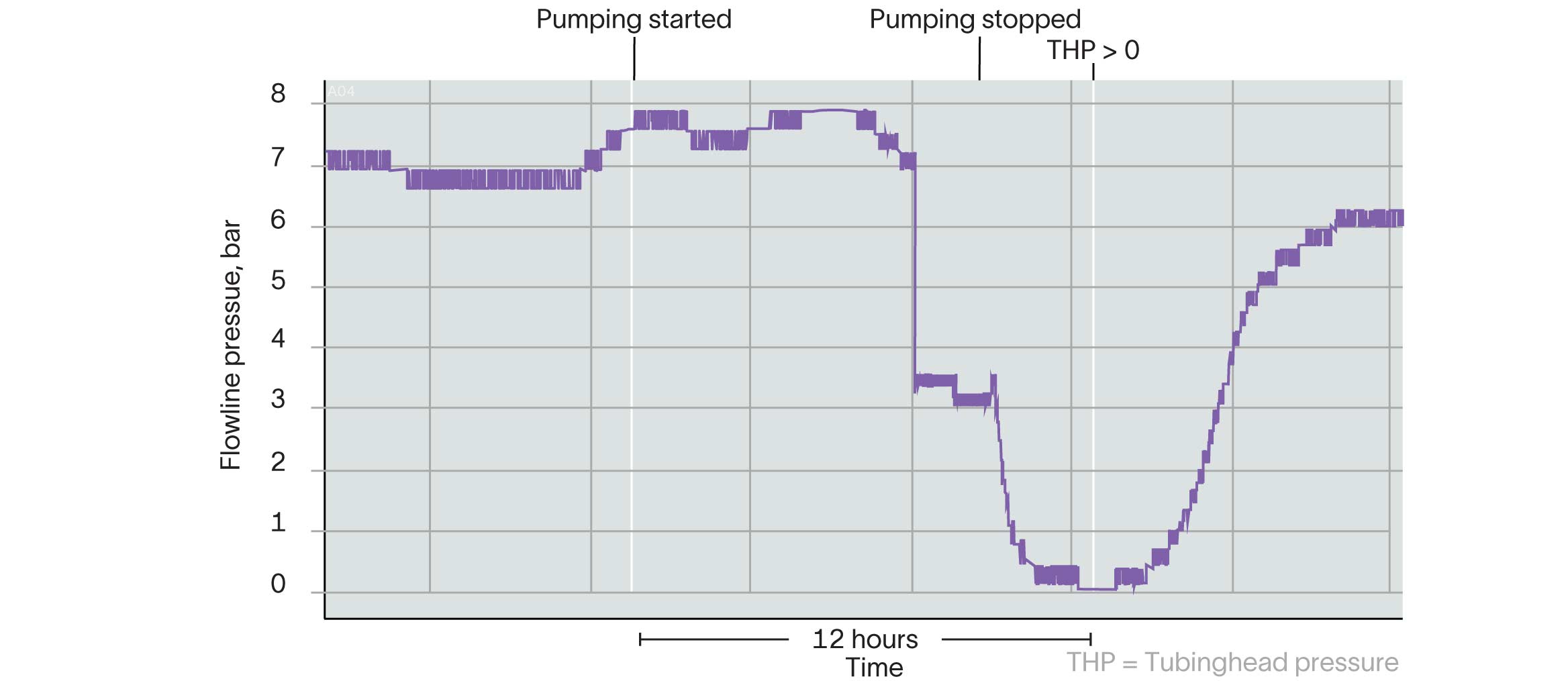

When the SCSSV became stuck in the open position, BaSO4 deposition was suspected as the likely cause. The consequent well integrity risk led to shutting in the well and loss of production. The operator planned to deploy a water-based sulfate scale dissolver by bullheading from the surface. BaSO4 scale dissolvers are typically chelants, which grasp metal ions tightly so that they cannot be easily liberated by other substances. The process is relatively slow, with effective chelation taking up to 24 hours at the downhole temperatures typical in this field.

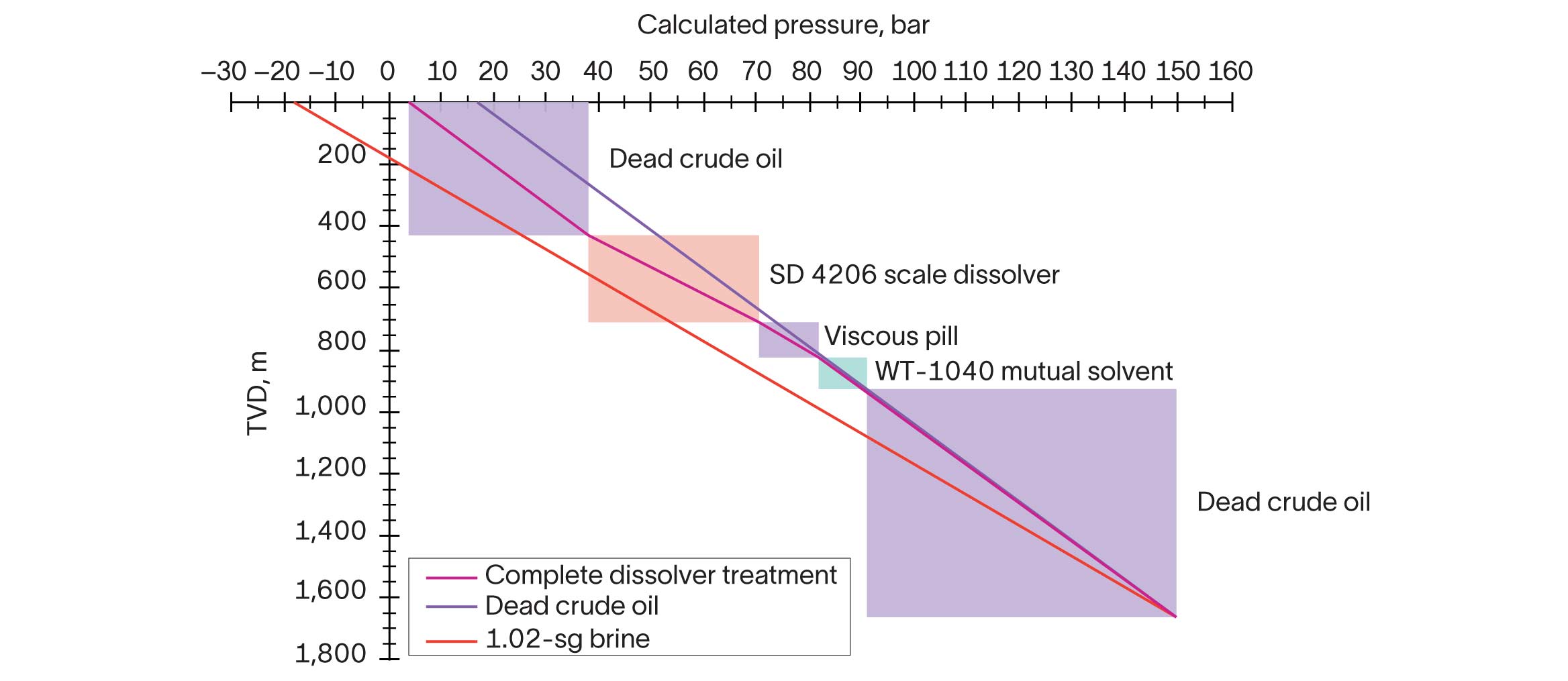

However, the reservoir pressure was too low to withstand a tubing column of water-based fluids with a density >1 g/cm3. Because of the resulting fluid loss, the scale dissolver would not stay in place across the SCSSV; instead, it would sink below the target area. Even if lower-density dead crude oil was used to displace the water-based well fluid, the denser aqueous-phase scale dissolver placed across the SCSSV—above the lighter crude—would immediately fall through the oil phase. A strategy was required to effectively deploy the scale dissolver and hold it in place for up to 24 hours.