Reduce operational risk while restoring permeability and production in impaired sandstone reservoirs.

Sandstone acidizing boosts deepwater well production 2.5-fold

An operator aimed to enhance the performance of a subsea production well off the coast of Angola, where formation damage had significantly reduced the productivity index. Conventional multistage sandstone acid systems posed challenges in stimulating the long openhole producing section, leading to the selection of OneSTEP EF™ efficient, low-risk sandstone stimulation solution for its single-stage efficiency and superior precipitation control. Its successful implementation transformed the well into the operator’s top producer in Angola.

The primary objective was to remove near-wellbore damage in a deepwater subsea well suffering damage from mudcake, loss control material, organic deposits, silts, clays, and fines migration—factors that reduced the productivity index (PI). Complicating matters, the well featured a long openhole stand-alone screen (SAS) and a relatively low bottomhole static temperature (BHST) of 167 degF [75 degC]. The combination of complex damage mechanisms and a challenging completion configuration made conventional multistage sandstone acid systems a high-risk option because of poor placement efficiency, high precipitation risk, and the operational volume requirements of multistage acid treatments.

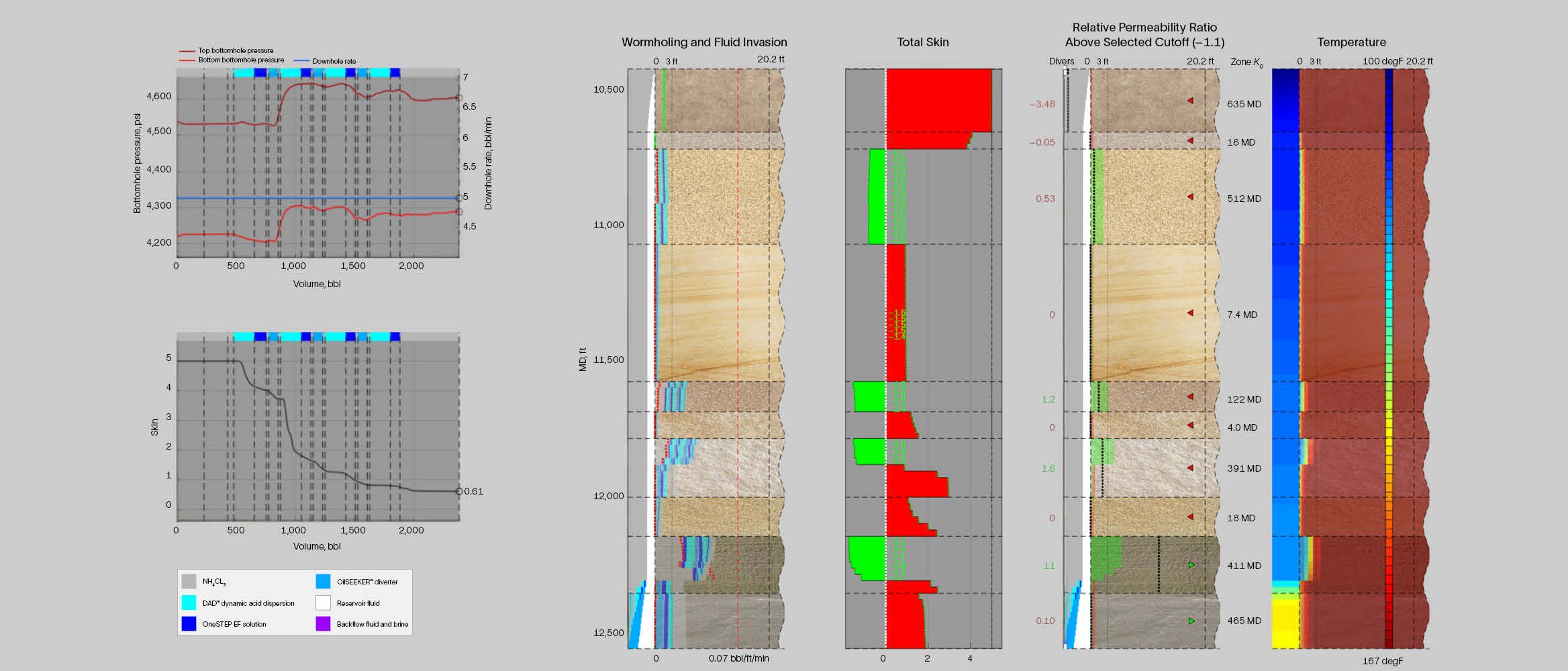

To optimize sandstone acid stimulation, SLB conducted extensive diagnostics and lab testing, including core flow, dissolution, inductively coupled plasma, and fluid compatibility tests to assess and validate the formation damage mechanisms. Additionally, the Kinetix Matrix™ stimulation design software optimized fluid pumping schedules, placement, and diversion coverage.

Based on these findings, SLB recommended the OneSTEP EF solution, engineered to adapt to complex mineralogies across a broad temperature range while minimizing undesirable precipitates to ultimately improve sandstone acidizing success rates. Operationally, the OneSTEP EF solution consolidates multiple acid stages required in conventional systems into one, reducing fluid volume by up to 50%, shortening pump times, enhancing efficiency and safety, and ensuring effective stimulation coverage across long openhole producing sections.

This well marked the world's first deepwater offshore application of the OneSTEP EF solution. The stimulation treatment reduced total treating fluid volumes by 34% and delivered a 2.5-fold production increase, making it the top-producing well for the operator in Angola.