Symmetry pipe

Integrated approach to optimize production

Symmetry Pipe relies on state-of-the-art thermodynamics that enable you to apply the same fluid characterization, physical properties, and phase equilibria throughout the gathering system, processing, refining, final products, and by-products. This provides a more consistent model and includes the ability to track all the components from end-to-end.

Integrated approach to optimize production

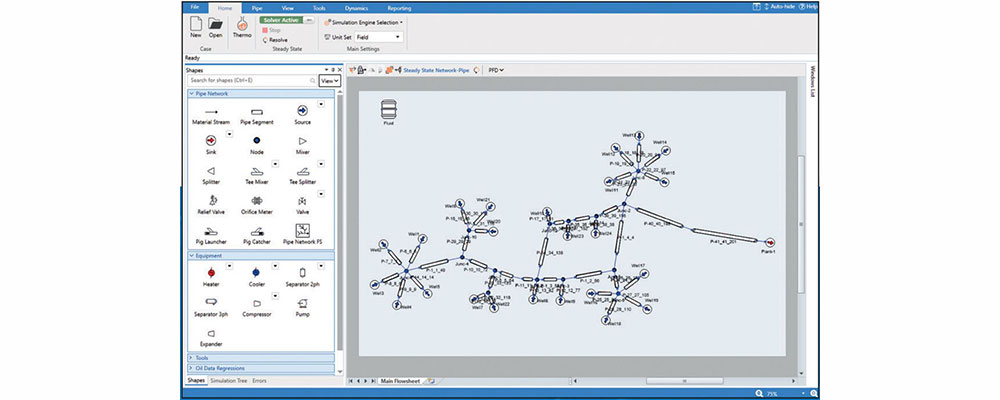

From a simple straight pipeline to a highly complex network, you can run integrated analyses in steady-state or transient mode. Use steady state for cases such as network debottlenecking. Transient conditions can be used to analyze flow assurance conditions, such as liquid loading, pigging scheduling, and slugging.

Ensure pipeline reliability

Pipeline reliability depends on continuous flow from wells to processing units, at a flow throughput rate that’s as close to the design rate as possible. Symmetry Pipe provides dynamic and steady-state analysis to help you

- optimize design using thermohydraulics

- assess multiphase production fluids through pipelines

- predict, prevent, and remediate flow stoppages, such as slugging, wax, and hydrates.

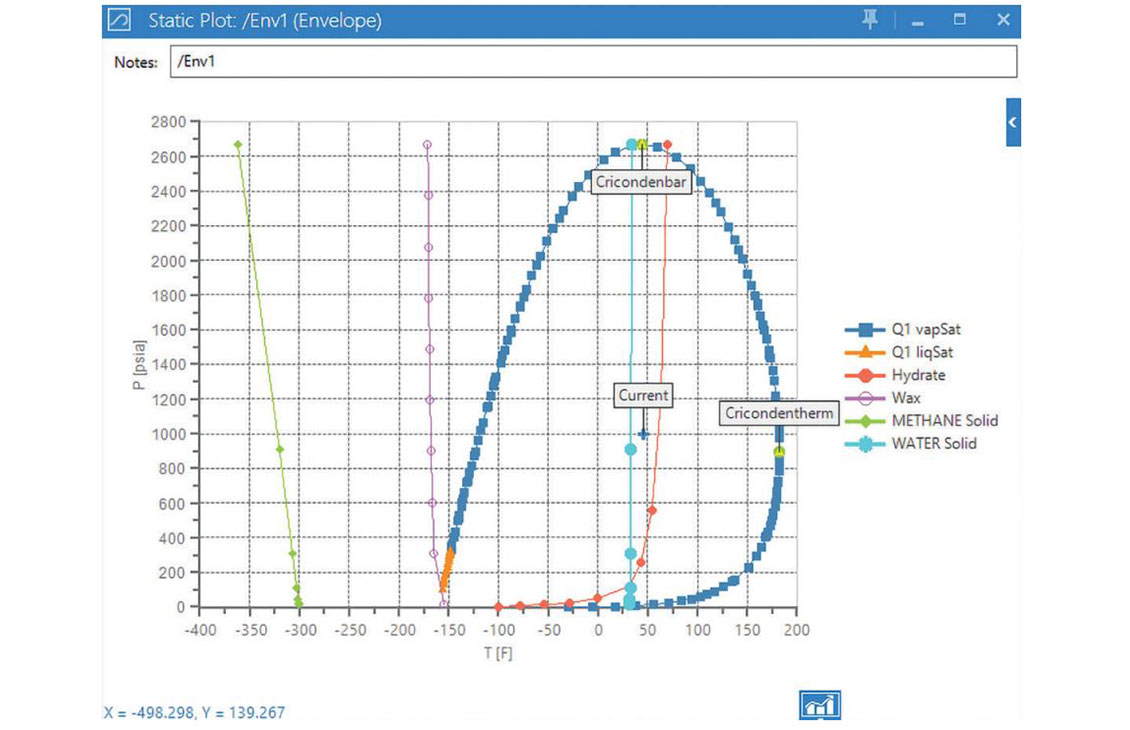

Consistent property package across the integrated system

Symmetry process simulation software has a consistent property package and fluid characterization that can be used throughout the simulator with both steady-state and dynamic engines.

Fluid characterization suitable for different operations

The platform contains a variety of fluid characterization methods for systems, ranging from heavy oil to liquids produced with gas. Simulations can use a consistent slate of components, regardless of the number of different fluids when using n-paraffin, isoparaffin, olefin, naphthene, and aromatic (PIONA) -based characterizations. These types of fluids track the molecular structure of the different sources, enabling you to consistently estimate property when material is blended.

The streamlined workflow in the Pipe workspace enables engineers to build models for any stage of the asset life cycle, from field development to asset production operations optimization.

The Symmetry platform has consistent thermodynamics and fluid characterization methods that are used in both steady-state and dynamic engines from the field, pipe network, processing plants, and flare systems.

The Pipe workspace is equipped with industry-standard flow models including generalized multiphase mechanistic models like Petalas and Oliemans, superior mechanistic models such as OLGAS 2 and 3 phase interface, as well as the traditional empirical methods.

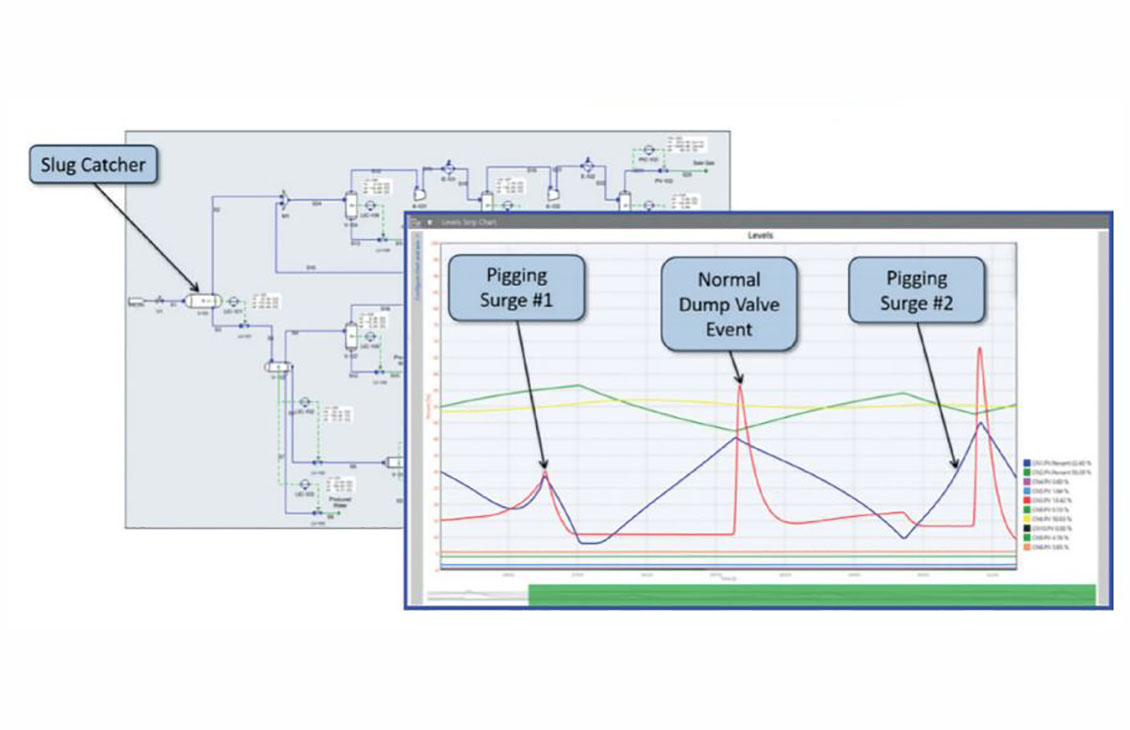

Pigging

- Insert pigs directly in the pipeline or through the pig launcher in the dynamic model.

- Track pig location and velocity throughout the gathering system/network.

- Predict liquid holdup and pressure loss as pig proceeds down the pipe and sweeps liquid ahead.

- Pig one or multiple pipes—there’s no limit to the number of pipes in a network that can be pigged.

- Analyze different mechanisms to mitigate large liquid slugs leaving the pipeline into the downstream slug catcher, including detailed control schemes.

- Use Scheduler block to develop a pigging schedule for pipelines at regular intervals.

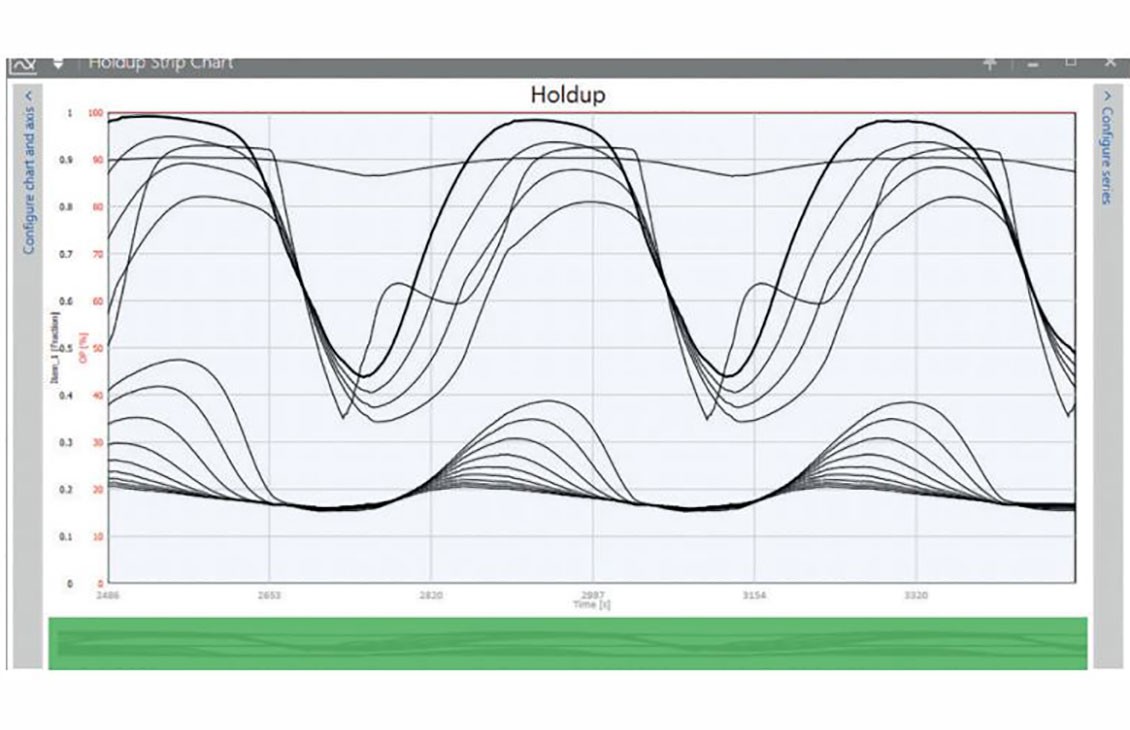

Slugging

- Calculate liquid holdups and slugs induced by elevation/ terrain changes in pipelines— important for configurations such as risers.

- Calculate slugging based on flow rate and operational conditions (e.g., turn-up slug).

- Monitor the formation and burping of liquid slugs in pipelines.

- Evaluate slug catchers based on liquid slugs/holdup.

- Slug mitigation measures assessment (topside choking, gas lift, etc.)

Flow Correlations

- Generalized multiphase mechanistic models (Petalas, Oliemans, etc.)

- Available superior mechanistic flow models such as OLGAS 2 and 3 phase interface

- Traditional empirical methods (Beggs and Brill, Lockhart & Martinelli)

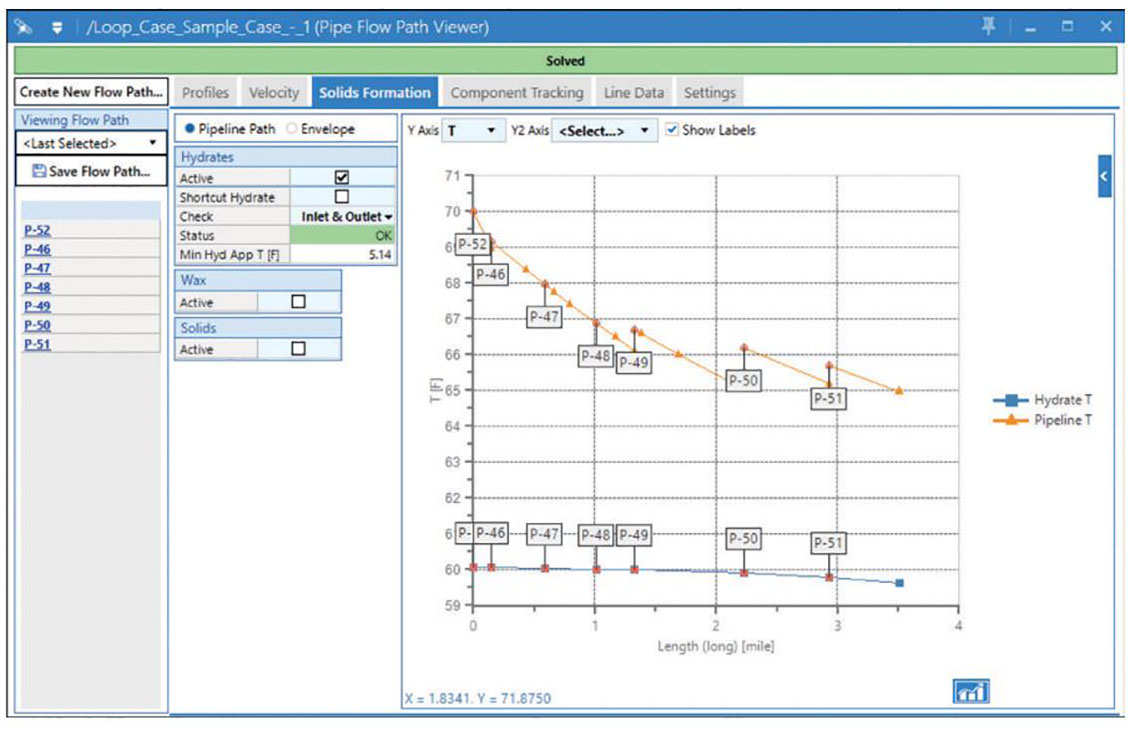

Flow Assurance

- Rigorous hydrate formation estimation with or without inhibitors

- Wax formation

- Erosional Velocity

- Solid formation

- Component tracking

- Extensive list of physical and transport properties

- Access to a comprehensive set of productivity tools: case studies, custom calculations in process calculators, and flexible plotting of virtually any variable

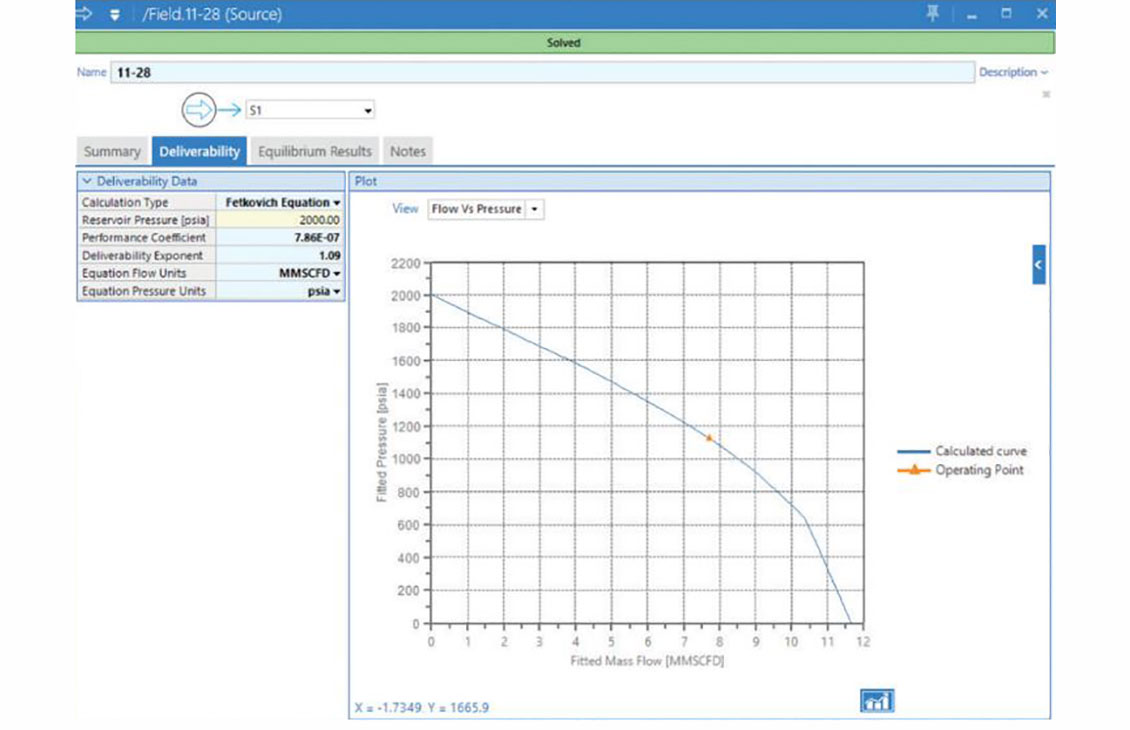

Well Deliverability

Well performance can be modeled using the Deliverability option, which enables you to input a relationship between well flowing pressure and well production rate.

- Tabular data (Q versus P)

- Linear relationship

- Fetkovich equation

- Vogel equation

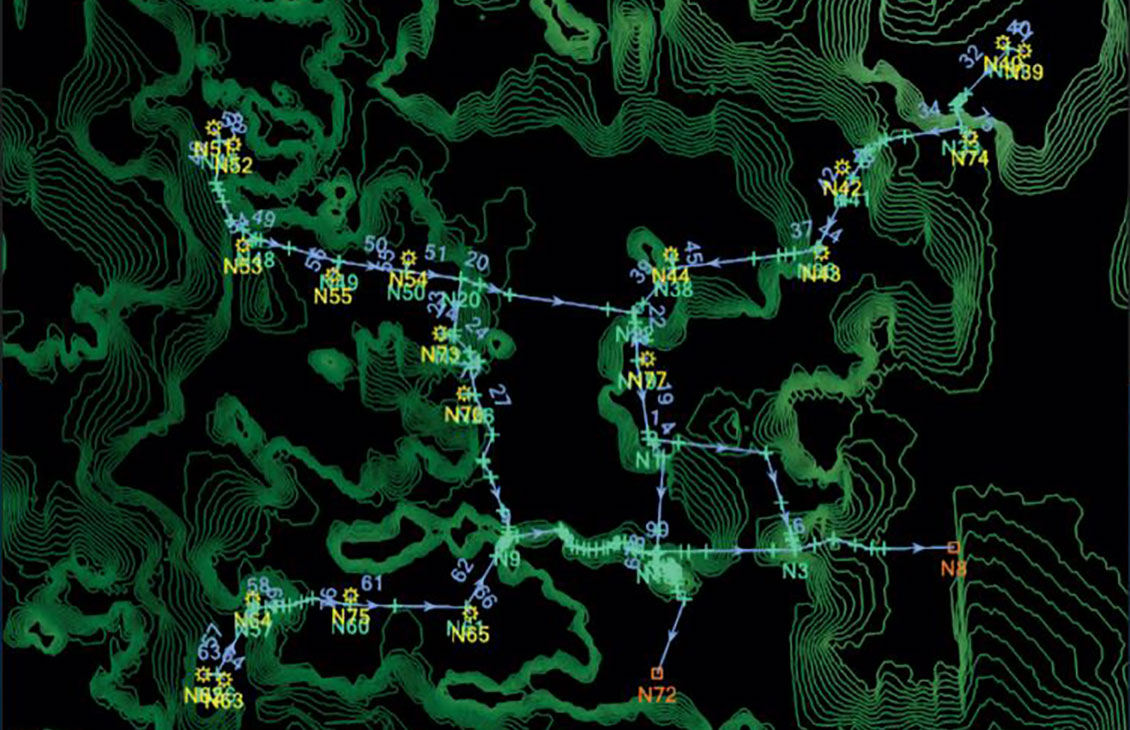

Pipe Network Creation

- Build a network using terrain details based on digital elevation models (e.g. DEM files)

- Build pipe network models from shapefiles

- Resolve inconsistencies and connectivity issues using the network connection tool

NExT Symmetry training courses

NExT offers a comprehensive training program to support users of the SLB software, plugins, and other software products.

Process Simulation in Action Webinar Series

Catch the latest Symmetry and Flaresim software updates, pro tips, and industry solutions.

Learn moreIn this section

-

Symmetry dynamics

Dynamic features and user friendliness in a unified life cycle environmentReducing software costs and making dynamic simulation affordable to companies in the process industries.

-

Symmetry field

Fully integrated reservoir/multi-phase gathering system simulatorSymmetry Field Workspace models large and small gas properties.

-

Symmetry flare

Model the complete flare systemThe Flare workspace empowers users to verify safety systems completely, efficiently, and rigorously.

-

Symmetry pipe

Integrated approach to optimize productionIntegrated approach to optimize production.

-

Symmetry process

Advancing process understandingAdvancing process understanding.

-

Symmetry thermo

An extensively validated thermodynamics library with almost 20 years of program refinementAn extensively validated thermodynamics library with almost 20 years of program refinement.

Discover digital

Software

World leading software built to solve your challenges.

Living Digital

See the latest digital articles, webinars, podcasts, blogs and tech talks.

Support

Access a variety of technical assisted support services and submit support requests online.