Autonomous Inflow Control Devices - Type 2N

Delay and suppress unwanted water and gas breakthrough

ResFlow™ AICD 2N is a cyclonic-flow-based autonomous inflow control device (AICD) that improves well performance by autonomously managing inflow to restrict gas and water while maintaining optimal oil production rates. Moreover, by applying higher backpressure in high-permeability or high-pressure zones, these devices promote uniform drawdown across the reservoir and minimize bypassed reserves, further increasing total recovery. This dynamic response reduces the volume of unwanted fluids handled at surface, lowers operational costs, and extends well life with fewer interventions.

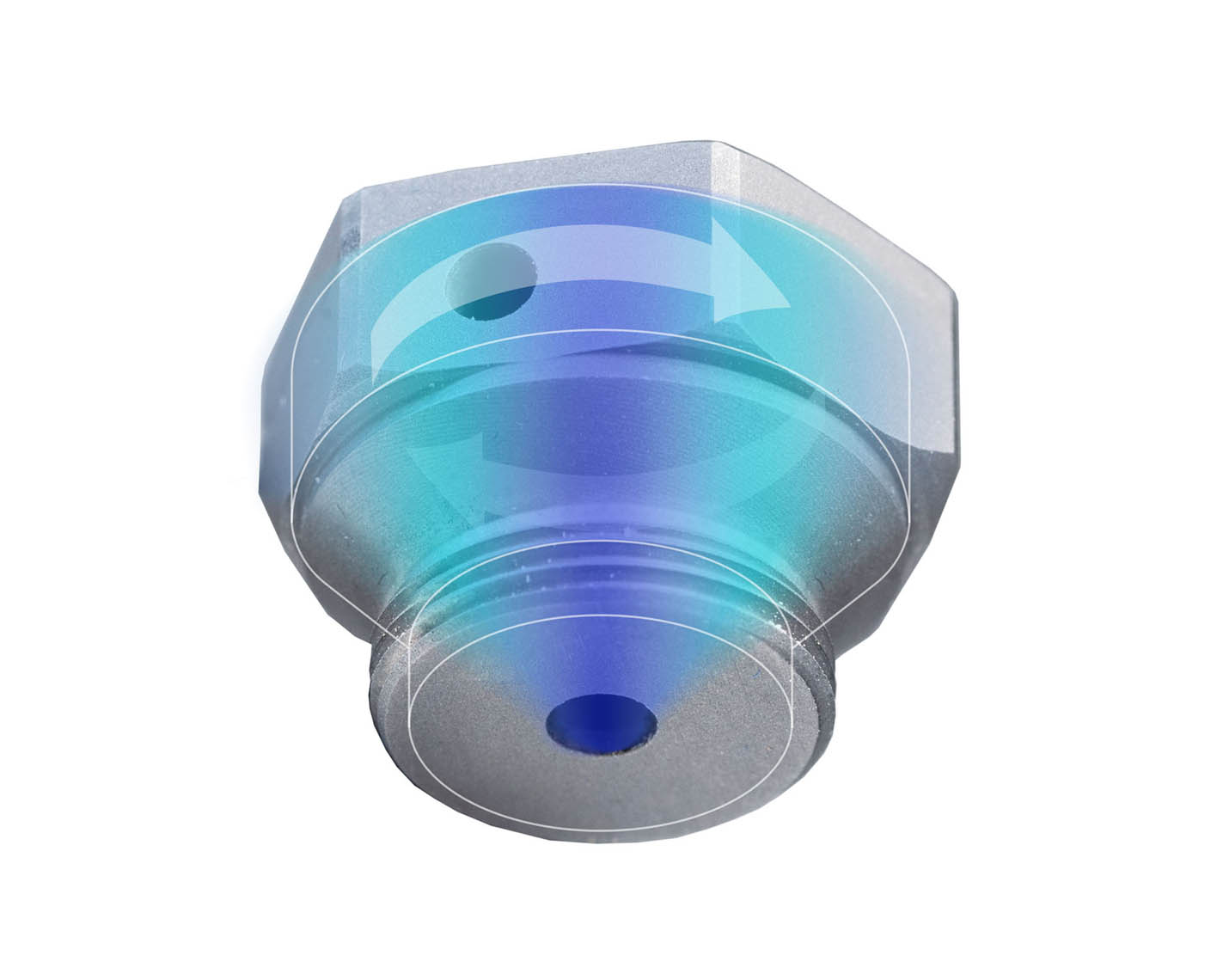

Produced fluids enter the ResFlow AICD 2N through the screen assembly. Within the device, the flow path induces rotational motion that differentiates fluid phases. Oil exits with minimal pressure drop, similar to passive ICDs. In contrast, lower-viscosity gas and water experience higher rotational velocities that generate greater pressure drops, restricting production of these fluids. The higher the proportion of gas or water, the greater the restriction. This autonomous mechanism operates without external control or moving parts. The ResFlow AICD 2N device boosted production by 41% and cut emissions in Peru by reducing water production.

Separate optimized devices are available. Log in to download the specifications which we update as we grow our available options.

- Oil wells with anticipated early gas or water breakthrough

- Openhole horizontal completions

- Heterogeneous reservoirs with permeability contrasts

- Reservoirs where passive ICDs are ineffective

- Fields with high gas- and water-handling costs

- Gravel-pack completions (as part of an inner string)

- Enhance well cleanup efficiency by balancing inflow from heel to toe

- Delay and minimize gas and water breakthrough and production

- Increase recovery by promoting uniform reservoir depletion

- Save rig time via simplified installation

- Adjust configuration at the wellsite, using the latest log data for optimal performance

- Simplify multizone production management

- Lower total unit development costs

- Minimize workover frequency with robust, durable hardware that resists erosion and plugging

- No moving parts

- Tungsten carbide nozzles for long-term durability

- Field-proven modular design

- Compatibility with all SLB screen filter media

- Optimized design using ICD Advisor™ inflow control device planning software and Eclipse™ reservoir simulator