Minimize perforation damage and boost productivity with the PURE system's optimized dynamic underbalance.

Successful subsea well reactivation and production enhancement in the UK North Sea

A UK North Sea operator successfully reactivated a long‑term shut‑in subsea well using advanced perforation techniques from SLB and a tailored intervention strategy. The operation restored production to levels exceeding preshut-in rates, maximizing economic recovery and enhancing field productivity.

The UK North Sea operator faced the challenge of reactivating a long-term shut-in subsea well while addressing well integrity issues and mitigating near-wellbore formation damage caused by scale buildup. The goal was to restore production to preshut‑in levels, ensuring optimal productivity and economic recovery.

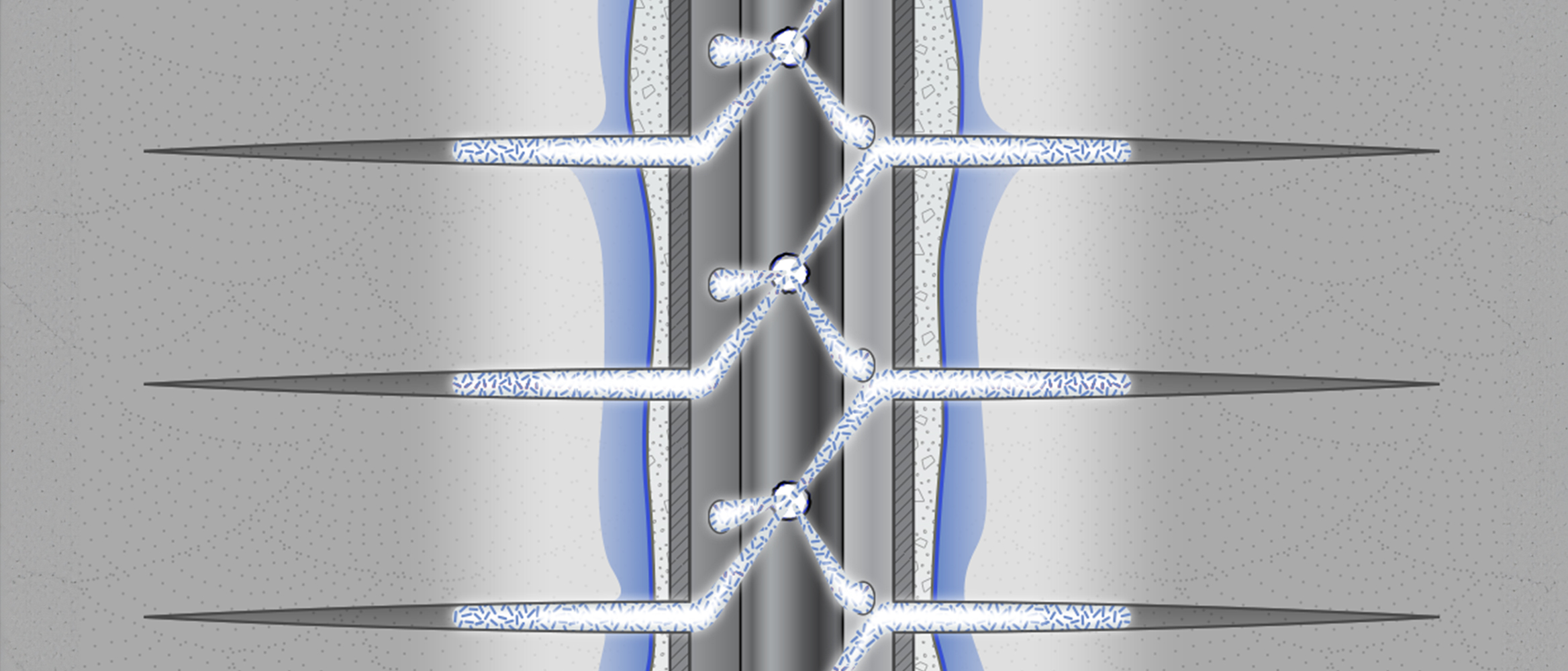

SLB recommended a comprehensive approach, leveraging Intervention Advisor™ collaborative intervention method selection solution for collaborative and detailed solutions selection and planning. The analysis revealed increased skin and formation damage, necessitating a customized perforation strategy. The solution included perforating designs using the PURE™ clean perforations system, the extra-deep penetration capabilities of PowerJet Nova™ extradeep penetrating shaped charges, and dynamic underbalance perforation using P3™ postperforating treatment to clean out scaled perforations and create new, high‑efficiency tunnels. The intervention was performed using a light well intervention vessel (LWIV).

The intervention was executed as planned, and the subsea well was successfully reconnected to the facility. Initial hydrocarbon production exceeded expectations, and stabilized flow rates were significantly higher than preshut‑in levels. This outcome not only restored the well’s productivity but also maximized the economic recovery of the asset.

The operator benefited from higher-than-expected initial production rates, stabilized flow rates exceeding preshut‑in levels, enhanced economic recovery and field productivity, and minimized risk of nonflowing well postreconnection.

This successful operation demonstrated the value of an integrated approach by SLB, combining advanced technology and meticulous planning to overcome the complexities of subsea well interventions.