Petrel Advanced Completion Optimization

Using Intersect high-resolution reservoir simulator

Incorporates a workflow for reservoir-centric lower completion design and interval control valve optimization across well life.

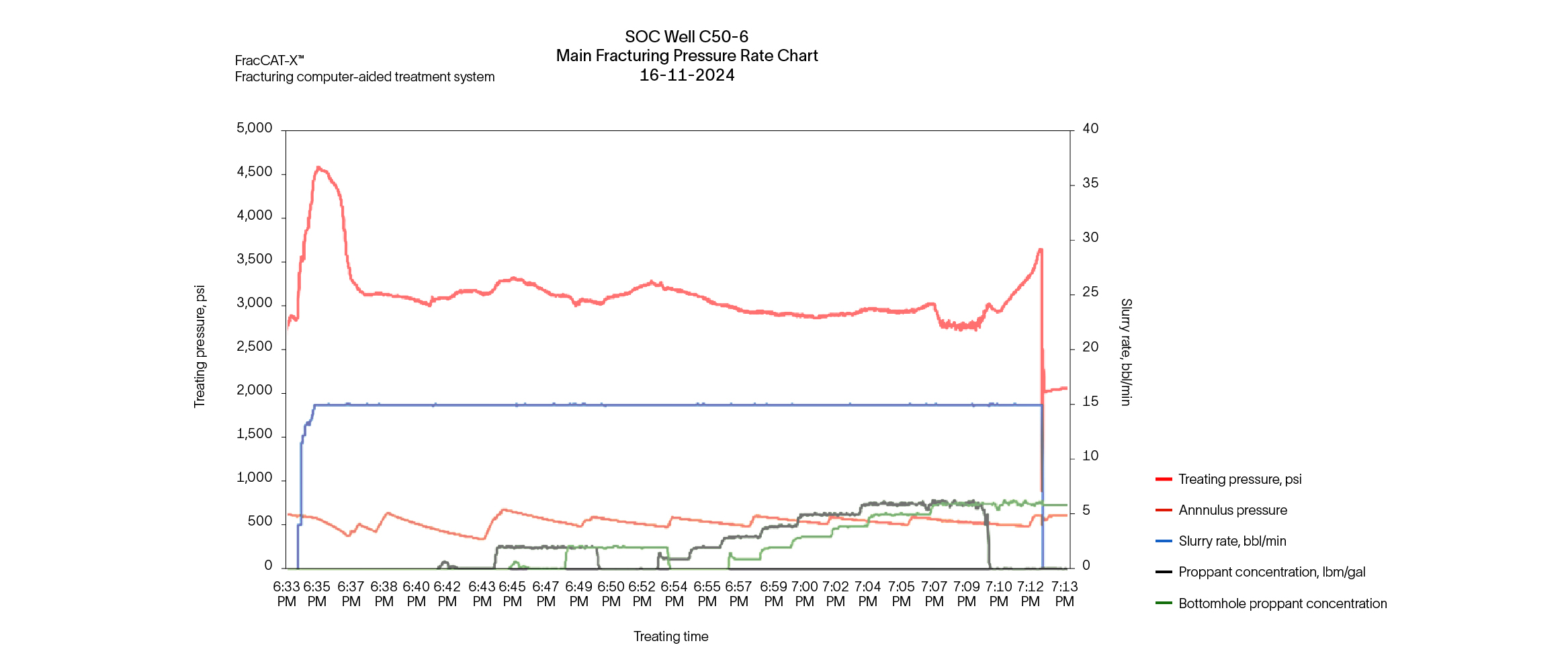

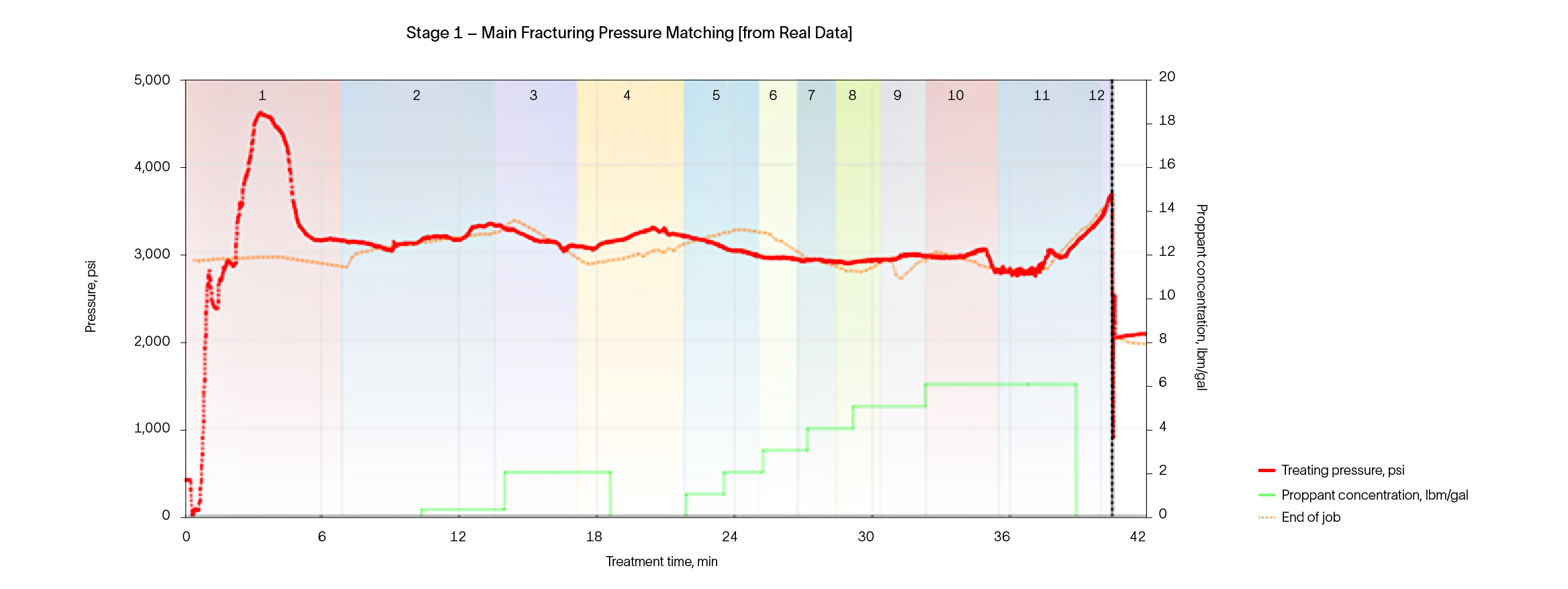

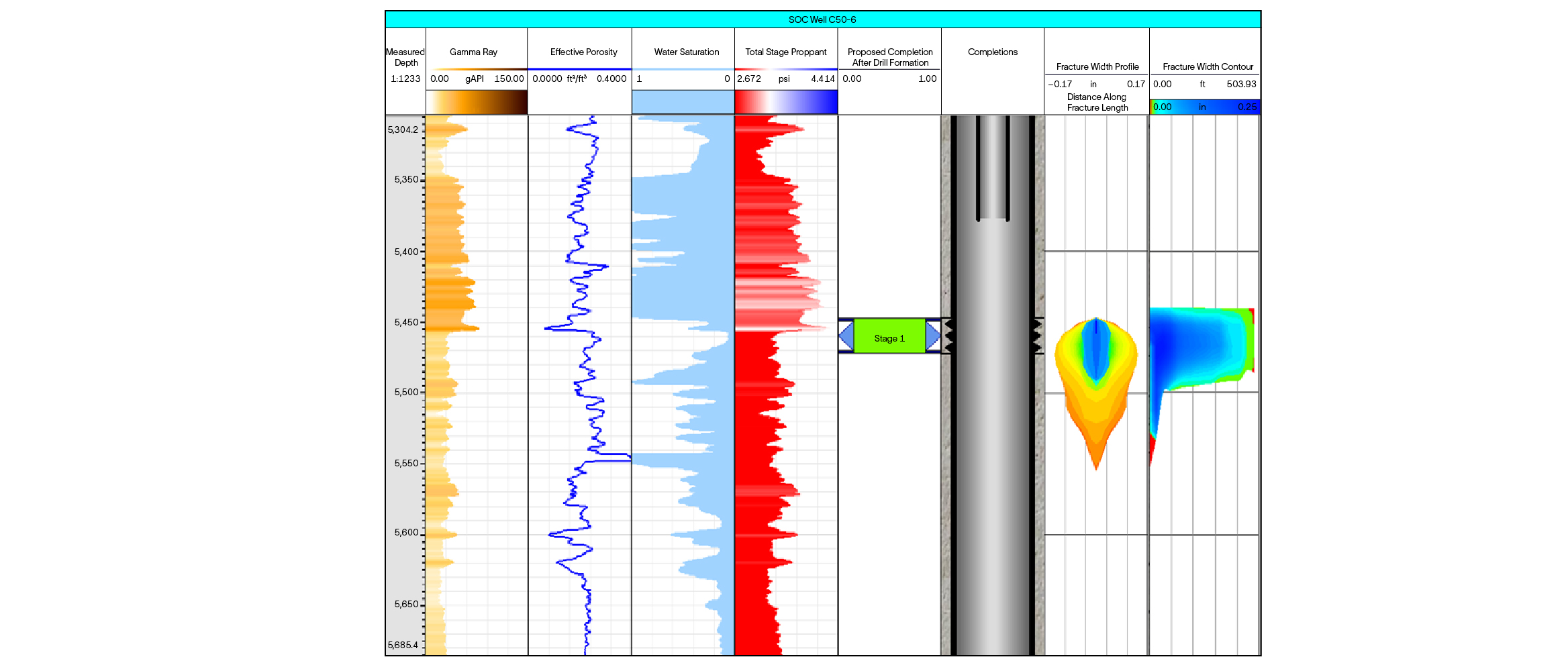

The Harash carbonate reservoir, located in Libya's desert, has long posed challenges for oil production due to its complex geology. The C50‑6 well, drilled in 1963 by SOC, was producing from multiple oil‑bearing layers situated above a high‑permeability water zone. Over time, the well's oil production declined significantly as the water/oil contact moved upward, leaving the well producing only 150 bbl/d with a 90% water cut.

SOC's primary objective was to enhance oil production while minimizing water production, thereby improving the well's profitability and operational efficiency. Traditional hydraulic fracturing methods were ineffective due to the lack of a strong barrier between the oil‑producing zone and the water zone below. Previous attempts to address the issue failed to deliver satisfactory results, prompting SOC to seek an innovative solution to isolate the water‑producing zones and optimize oil recovery.