DURAFLO Optimus

High-capacity two-tier composite shaker screens

The most rugged, long-lasting, and efficient screens available.

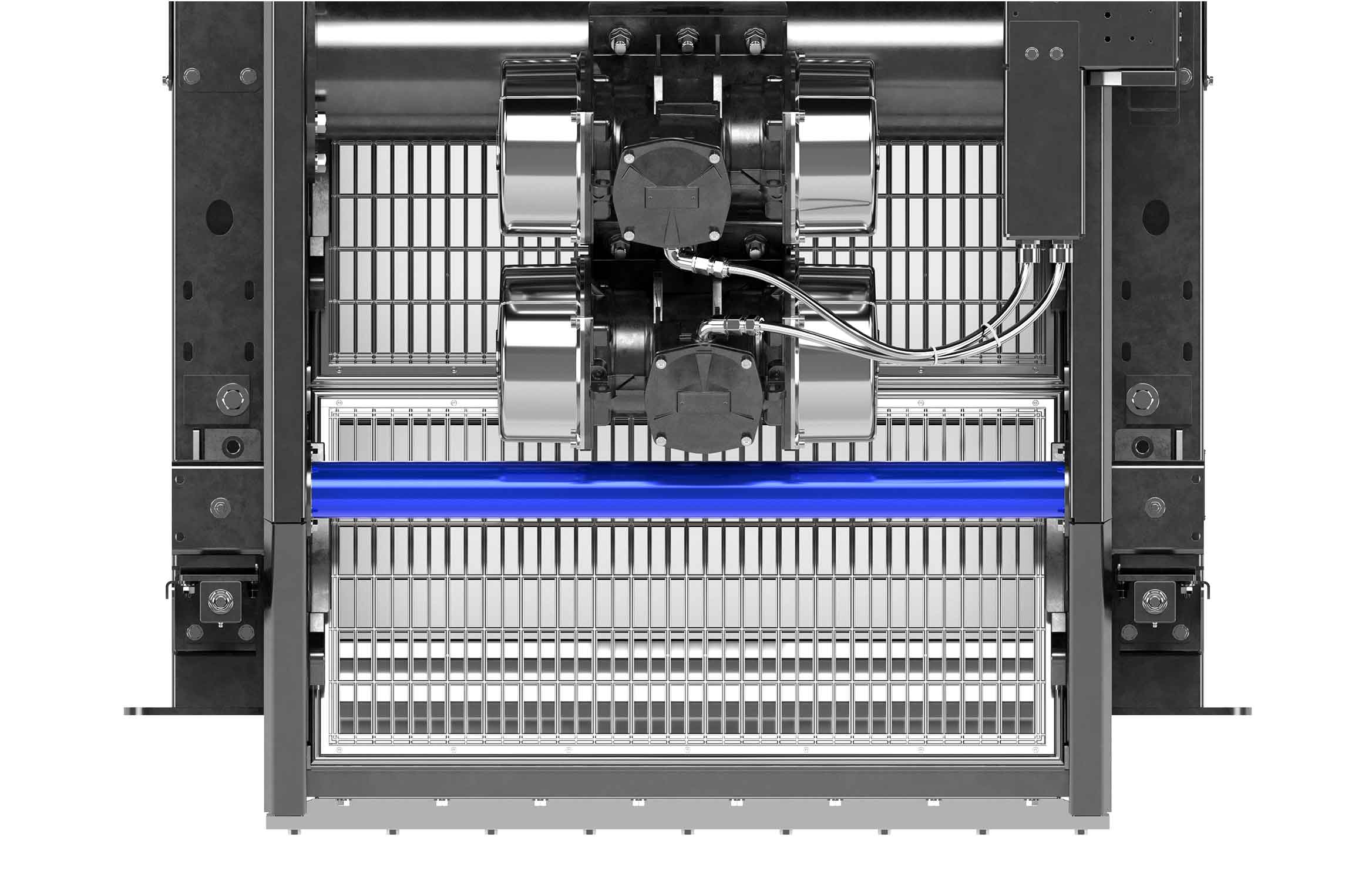

Designed for solids control in drilling operations, the MONGOOSE PRO™ dynamic dual-motion shaker combines balanced- and progressive-elliptical motion. It enables operators to switch motion on the fly as drilling conditions change without the need to suspend or shut down operations. NPT lost to changing out shakers to meet drilling conditions is no longer an issue. The MONGOOSE PRO shaker can also be retrofit onto third-party skids to reduce parts cost, solids bypass, noise while operating, and screen usage.

Combines balanced- and progressive-elliptical motion

Increases conveyance rates and shaker fluid capacity

The following SLB products are protected by patents in the U.S. and elsewhere. This website is provided to satisfy the virtual patent marking provisions of various jurisdictions including the virtual patent marking provisions of the America Invents Act and to provide notice under 35 U.S.C. §287. The following list of SLB products may not be all inclusive, and other SLB products not listed here may be protected by one or more patents.

MONGOOSE PRO dynamic dual-motion shaker: Protected by U.S. Patent US7810649. Additional patents may be pending in the U.S. and elsewhere.

The MONGOOSE PRO shaker is designed to work with DURAFLO composite screen, which provide a significant increase in fluid capacity as well as excellent resistance to blinding, providing dryer solids discharge and a larger net usable screen area.

Learn more