From rig to town: unified and standardized data at your fingertips

已发表: 05/20/2025

From rig to town: unified and standardized data at your fingertips

已发表: 05/20/2025

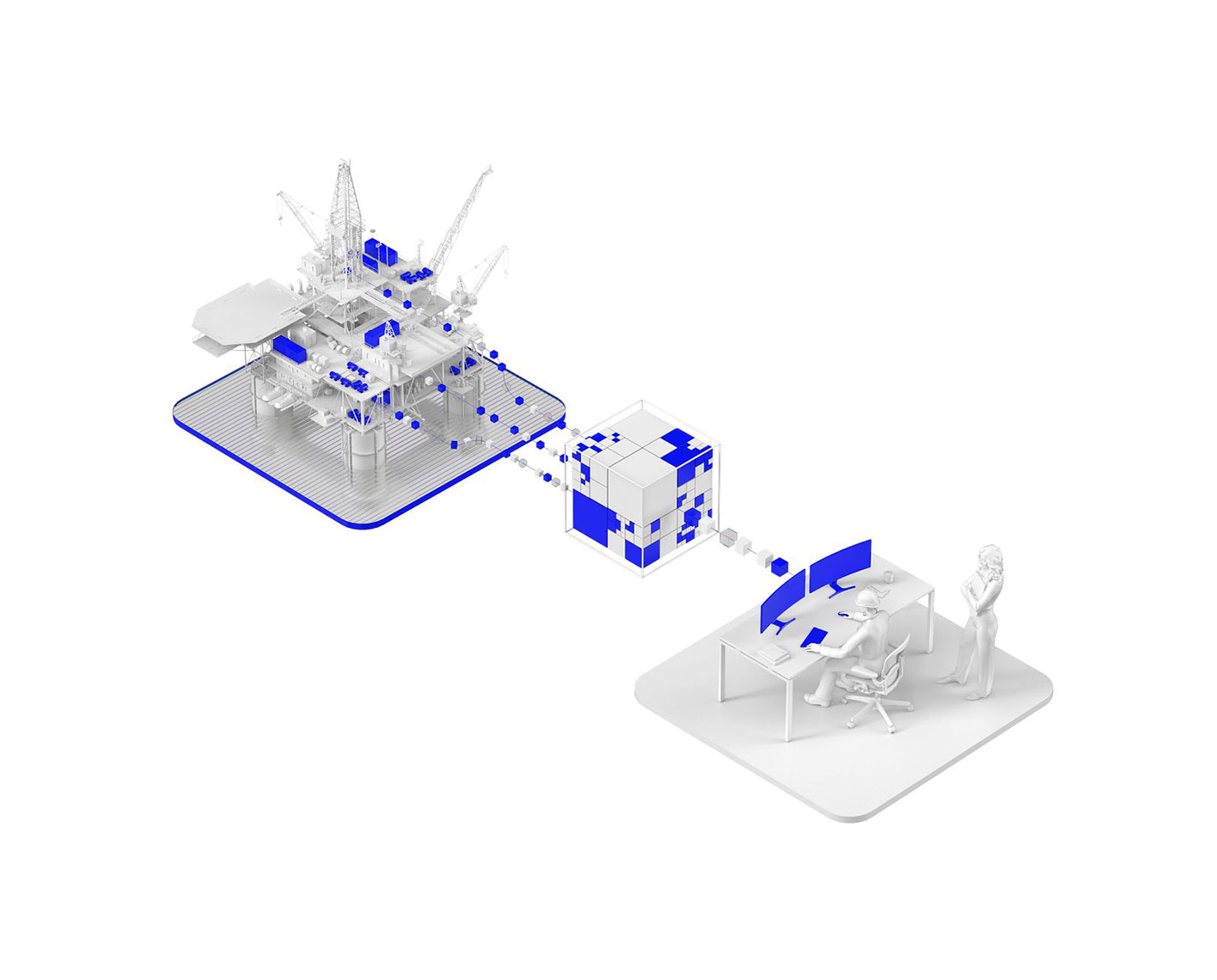

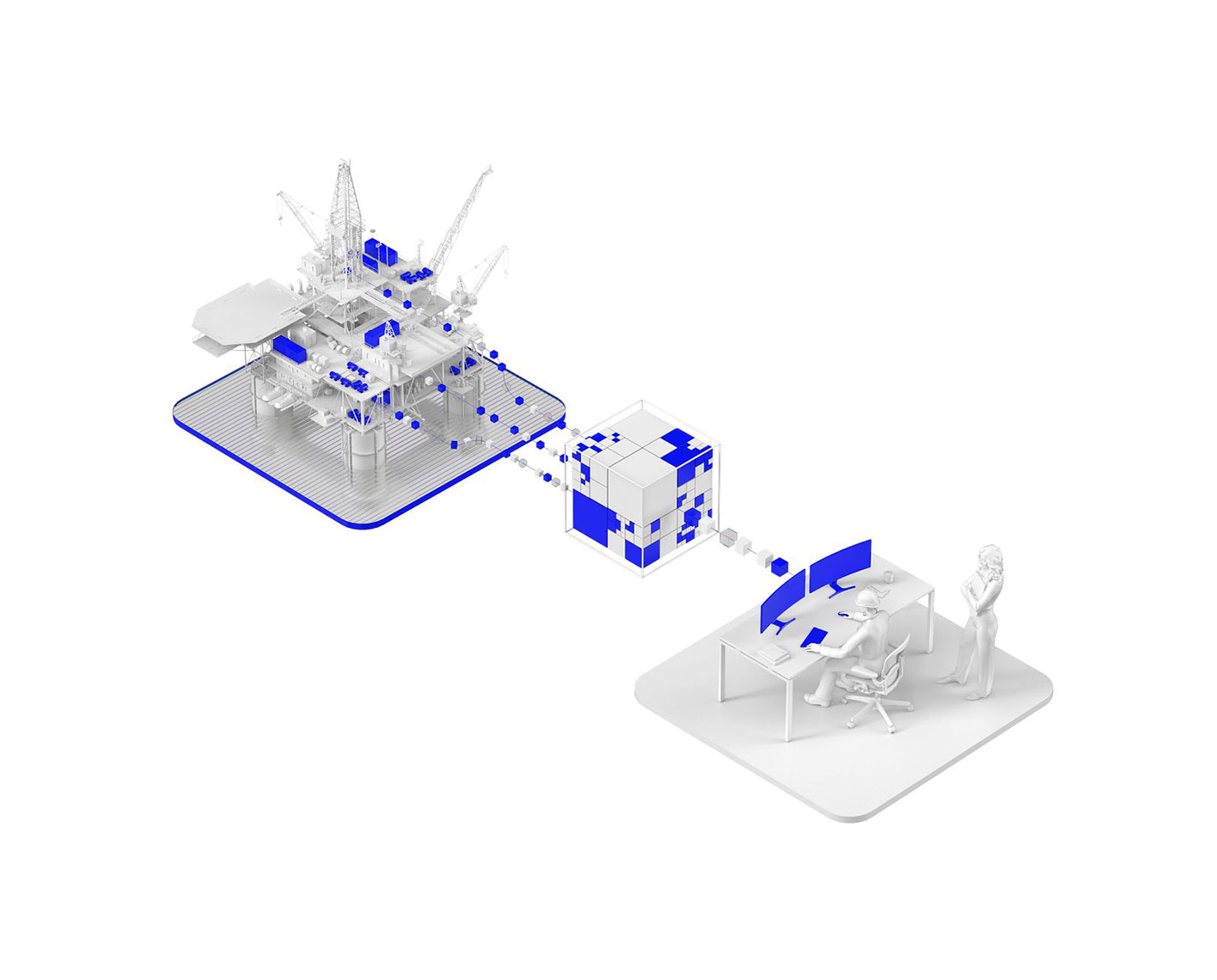

Bridging the gap between rig data and operational excellence

Today, advancements in equipment, processes, and technology are transforming well construction operations. These innovations promise safer, more efficient, and emissions-friendly practices. However, they also generate and utilize an unprecedented volume of data, bringing with it both challenges and opportunities. Enter DrillOps™ data aggregation and delivery—a vendor-neutral solution that is part of DrillOps intelligent well delivery and insights solutions. This cutting-edge solution integrates all surface, downhole, and equipment data into a single ecosystem for aggregation, transmission, visualization and delivery. Let's explore how the automation and integration features of DrillOps data aggregation and delivery make it a must-have for any drilling operation.

Streamlining operations with automation

Automation is at the heart of DrillOps data aggregation and delivery, offering numerous benefits to the well construction process. The system seamlessly aggregates data from multiple vendors and sources on the rig, automatically aligning it with customer-defined conventions and standards. This creates a standardized, unified, quality-controlled dataset without the need for manual intervention. Its flexible and open framework also enables custom computations and visualizations to be added directly at the rig site, enhancing operational efficiency. Moreover, the solution's zero trust architecture supports the deployment of antivirus software and other security measures at the rig site, ensuring continuous validation of cybersecurity compliance in line with industry standards.

Automation also plays a crucial role in buffering and auto-reconnect processes. If the connection to town is lost due to satellite or cable issues for instance, the system automatically buffers the data collected on the rig for up to a week. Once the connection is re-established, the system streams the buffered data to town, filling any gaps caused by the lost connection. This entirely automatic process eliminates the need for manual reconnection and retransmission, helping to ensure uninterrupted operations even in areas with frequent network connection issues. The dedicated service team also works to ensure that the edge devices remain operational, enabling users to log in at any time to access their data and feel confident that any query can be addressed and data quality assured 24/7.

The system operates on a data-agnostic edge device that can connect to any service company’s data stream, supporting numerous data protocols. With edge orchestration, DrillOps data aggregation and delivery enables remote monitoring and management of services and infrastructure on the rig, enhancing operational security. This includes monitoring CPU and memory usage, identifying if the edge device is overloaded, and automatically notifying users if certain services or devices are not performing optimally. Automated deployment and redeployment of software to edge devices further reduces the need for manual intervention.

From rig to town—a harmonized data journey

The edge device facilitates multi-application execution, allowing other DrillOps solutions modules such as DrillOps advisory and DrillOps automation, and DrillOps procedural adherence to run on the same device at the rig site. The plug-and-play architecture resembles an application store, enabling customers to choose and install the applications they need. This approach means users can tailor the system to their specific needs, adding only the applications relevant to their operations. It also simplifies the updating or replacement of applications as new versions or better solutions become available.

The unified data ecosystem facilitates smooth integration and seamless data flow between the rig and the town, effortlessly handling unit conversions for hassle-free data transfer. This bidirectional flow fosters true integration, optimizing operations through contextualized data synchronization tailored to specific customer needs. Real-time visualization offers access to all streamed data in various formats, while customizable dashboards allow users to view the data they need, precisely when they need it. The WITSML store provides access to all collected data, supporting the latest WITSML standards, including versions 1.3.1.1 and 1.4.1.1 over ETP 1.1, along with all key WITSML standard objects.

DrillOps solutions also harness the cohesive dataset for modules such as DrillOps predictive analytics, facilitating deeper analysis and wider utilization across all DrillOps solutions models and third-party applications.

DrillOps data aggregation and delivery transforms drilling data management by standardizing and simplifying curve data across all sites, eliminating inefficiencies, and ensuring seamless integration. So, users can say goodbye to data chaos and embrace a smarter, more streamlined approach to curve data management.

The ability for insights, alerts, and additional information to be passed from town to rig, enhances the functionality of DrillOps advisory and DrillOps automation, such as for drilling parameter constraints and recommendations. This ecosystem allows us to leverage expertise from town-based subject matter experts (SMEs) and complex real-time modeling, while the rig provides control and high frequency (HF) interpretation. The ecosystem’s integration enhances the value of information gathered at the rig site, making it readily available for advanced analytics and informed decision-making, unlocking new opportunities for operational excellence.

The DrillOps data aggregation and delivery promise: reliable, efficient, and secure data management

DrillOps data aggregation and delivery offers a streamlined approach to managing data, integrating diverse sources into a cohesive, unified ecosystem for enhanced management and analysis. Its adaptable design supports various data protocols, enabling easy addition of new applications and services to meet diverse operational needs. By facilitating advanced analytics and seamless integration with third-party applications, DrillOps solutions enhance decision-making processes. Automation of data alignment, buffering, and reconnection processes boosts operational efficiency, minimizing the need for manual intervention.

With its robust, efficient, and cybersecurity-compliant framework, fortified by 24/7 support and monitoring, DrillOps data aggregation and delivery is truly a game-changer for the industry. To see how this innovative solution is transforming real-world operations, we invite you to explore some examples of its impact below.

Maurice Ringer

Maurice is product manager for DrillOps™ intelligent well delivery and insights solutions, and is responsible for digital products relating to monitoring, analyzing and optimizing drilling operations at SLB.

Maurice holds a PhD from Cambridge University, where he studied signal analysis, Bayesian inference, modeling, and optimization. He then joined SLB where he has been involved in drilling automation and real-time drilling in one form or another for more than twenty years, from MWD engineer to directional drilling, to developing new AI/machine learning (ML) techniques at the SLB Cambridge Research Centre, to mud logging project manager, to DrillOps solutions product manager.

Sameer Bisht

Sameer, a petroleum engineer by background, is the product champion for DrillOps™ data aggregation & delivery, bringing over 10 years of expertise in the real-time drilling industry. Played a pivotal role in establishing multiple real-time operational projects within SLB and has driven innovation, enhanced drilling performance, and optimized data-driven decision-making for his company.