Real-time fiber-optic interpretation and analysis for oil and gas, CCS and geothermal wells

Production intelligence across the full length of your wellbore

Reduces energy consumption by up to 99% due to higher operational efficiency; enables optimizing a full field development plan to potentially reduce the number of wells.

Reduces associated emissions because of reduced energy consumption compared with conventional borehole seismic acquisition.

Minimizes environmental impact to marine mammals—often associated with seismic operations—because of reduced source effort.

Optiq Seismic fiber-optic borehole seismic solution is part of our Transition Technologies portfolio. Learn about our approach to driving high performance sustainably and other technologies that can help minimize your well construction CO2 footprint.

Read MoreBorehole seismic (BHS) data bridges the gap between surface seismic and downhole measurements to delineate your reservoir properties. However, the opportunity to acquire borehole seismic data is often missed due to challenges associated with conventional BHS acquisition, such as low efficiency and high operational risks.

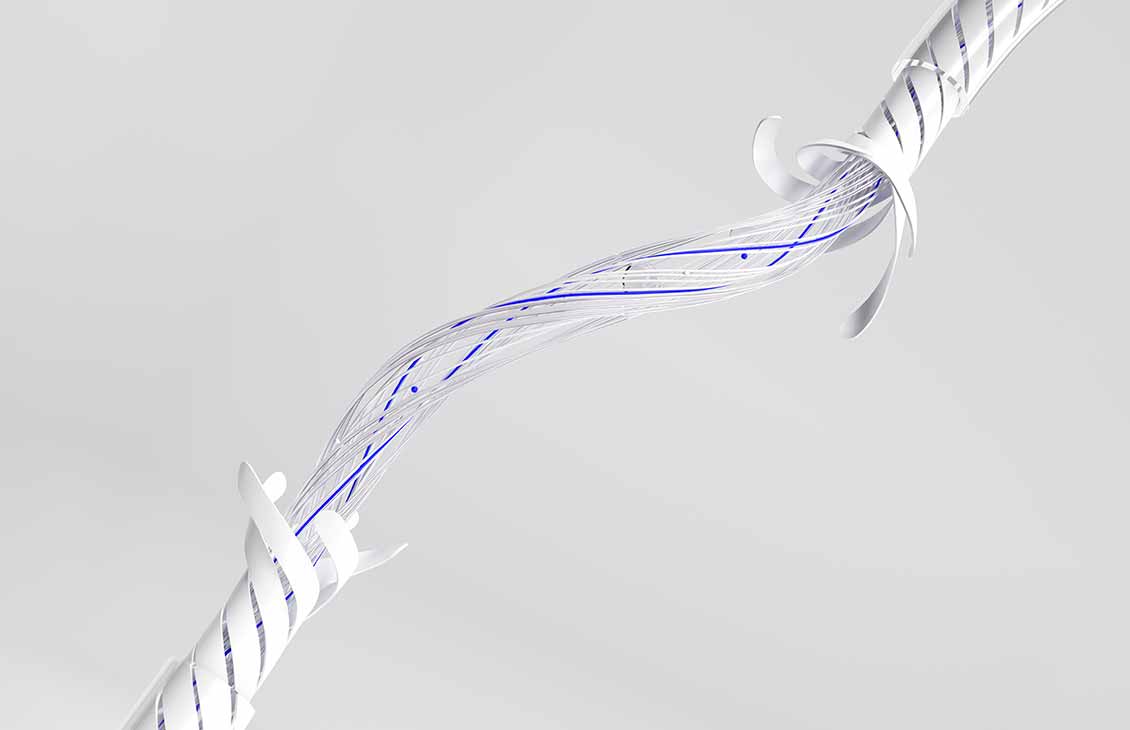

Part of the Optiq Schlumberger fiber-optic solutions family, the Optiq Seismic fiber-optic borehole seismic solution is a technological breakthrough that redefines BHS measurements, overcoming conventional BHS challenges. Harnessing the power of light via optical fiber, it leverages distributed acoustic sensing (DAS) technology; digital workflows; cloud-native software; and unique, temporary or permanent fiber-optic deployment options.

The innovative Optiq Seismic solution eliminates the need for downhole geophone arrays and makes every logging run or fiber installation an opportunity for seismic data acquisition. This enables you to streamline logistics and reduce operational risks, such as stuck tools or downhole failure.

The fiber optics are simply connected to an optical interrogator at surface and record seismic data in conjunction with other stationary logging services or on their own. And because of the distributed nature of fiber-optic measurement, unlike the conventional geophone acquisition method, it is no longer necessary to reposition a geophone array and repeat the source positions, reducing environmental impacts for both land and marine operations. With this new method, you can improve operational efficiency by up to 99%, significantly reducing energy consumption and carbon emissions.

The deployment-agnostic Optiq Seismic solution acquires zero-offset, walkaway, 3D seismic, 4D reservoir monitoring, and many more vertical seismic profiles (VSPs) with 1.5-m spatial resolution—and in minutes rather than the hours or days required using conventional methods. Furthermore, our integrated end-to-end workflows deliver the answer products up to 18× faster than the industry benchmark, so you can use insights in relevant time to optimize reservoir definition, imaging, evaluation, monitoring, and the drilling plan.

The solution only requires our optical interrogator (at surface) along with our innovative temporary or permanent fiber-optic deployment options (downhole).

Temporary deployment

You can deploy the solution using our unique fiber-optic wireline conveyances: Optiq TuffLINE torque-balanced fiber-optic wireline conveyance, with industry-leading safe working load (SWL), acquires VSPs in any exploration environment, including deep water. And now, you can also acquire VSPs during and production services run using Optiq StreamLINE polymer-locked fiber-optic wireline conveyance without any grease injection.

Permanent deployment

Our hybrid fiber-optic electrical cable can be installed permanently as part of your completion, either clamped to tubing or cemented behind the casing. Data from multiple wells can be acquired simultaneously without any deferred production, enabling you to monitor your reservoir performance and optimize your field development plan.

Our fiber optics work by pulsing a laser down the fiber and then measuring the phase change in the backscattered light that is caused by any strain induced on the fiber. Strain on the fiber can be caused by many things, such as seismic sources, passive seismic events, fluid flow, strain changes in the formation, temperature changes, and more. For borehole seismic, the strain imparted on the fiber is converted to a velocity using a strain-to-velocity algorithm to produce a geophone-equivalent response for integration in your existing workflows.

Unlike traditional point sensors that can only acquire data at the position of the sensor in the well, fiber optics are a distributed measurement, and data is acquired from the reflected laser light off the imperfections in the fiber along the full length of the fiber. Because the velocity the light travels in the fiber is known, it is then possible to solve for the depth that each reflection comes from.

Yes, the dynamic range and noise floor of our optical interrogator are superior to conventional geophones. We have demonstrated that Optiq Seismic solution can outperform conventional tools in case studies comparing Optiq Seismic solution data with the geophone-based approach.

Read case studies:

More than measurements, Optiq Seismic solution's integrated end-to-end workflows—backed by more than 40 years of leading domain expertise—deliver actionable insights up to 18× faster than the industry standard. You can now reduce reservoir uncertainty to fast-track time to first production or optimize your field development plan. The Optiq Seismic solution acquires data at the speed of light while also maintaining data quality by employing a proprietary multifrequency method that enhances the signal-to-noise ratio.

Digital planning tools enable presurvey modeling to optimize data quality. Advanced edge processing capabilities enable wellsite processing to deliver variable gauge-length processing for maximum signal-to-noise ratio in the reservoir section while preserving the frequency content of the data closer to surface. Furthermore, the denoising workflow delivers high-resolution images and enables you to understand the compartmentalization of the reservoir. And using digital microservices deployed at the wellsite, it is now possible to generate a corridor stack before completing wireline operations.

The following answer products are available at the wellsite: