Applications for valves and actuators

For a wide range of fluids

Decades of reliable service

SLB valves are used to direct, measure, and control the flow of oil, gas, and other industrial fluids as they are moved through flowlines, gathering lines, and transmission systems to refineries, petrochemical plants, industrial centers, data centers, and more.

Through innovative organic development and strategic acquisition, we have built a broad portfolio of valves that service the demands of global drilling, production, pipeline, storage, transmission, and critical-service applications.

Minimize fugitive emissions

Our valves are low-emissions certified to help you reduce environmental impact and reach your sustainability goals by mitigating or preventing unintended emissions.

Learn moreFugitive emissions certified valves with prequalified materials for long-term performance in ammonia production and transportation applications

Proven valve solutions for carbon capture, utilization, and sequestration

Optimal and reliable flow control for cooling fluids

Reliable flow control in high-temperature and abrasive environments

Prequalified valve designs and materials for long-term high performance in hydrogen applications

Biogas, renewable natural gas (RNG), sustainable aviation fuel (SAF), biodiesel, ethanol, and more

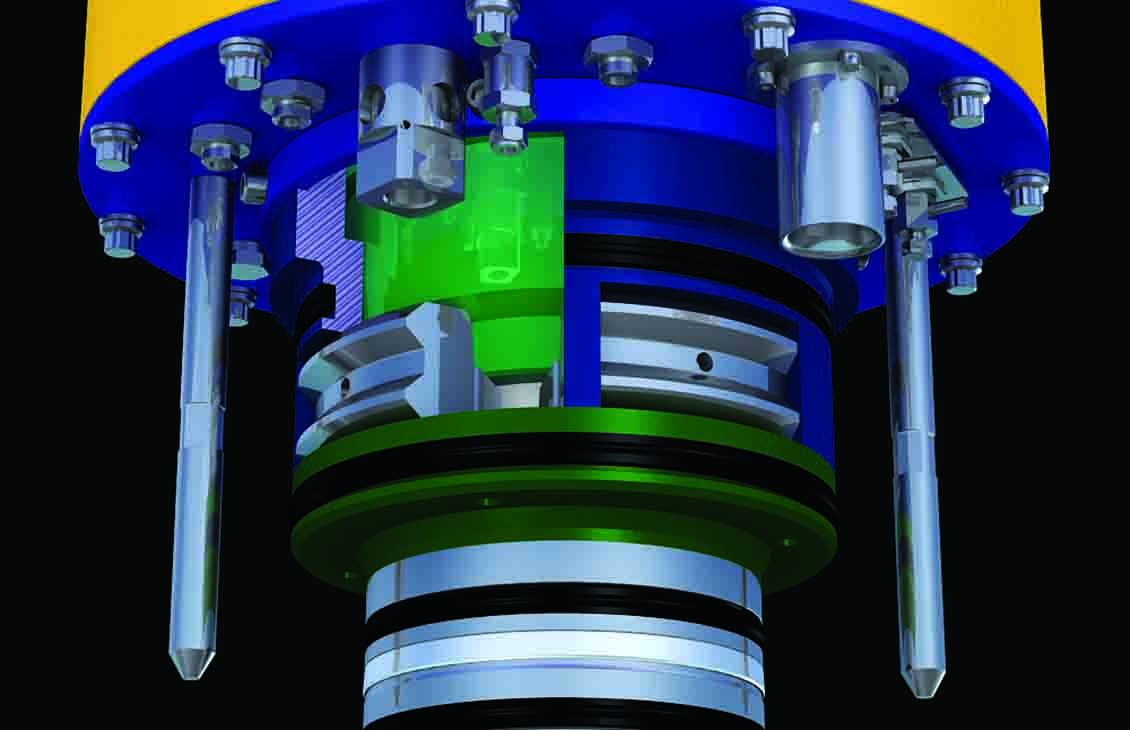

Subsea

Challenging conditions and depths

-

RING-O

Subsea valvesWithstand the external pressure caused by the column of seawater at operating depths.

-

Chemical Injection Metering Valves

Remotely operated, ROV-retrievable, self-regulating subsea CIMVsRedefine achievable accuracy with nonintrusive line-of-sight ultrasonic flowmetering.

-

Compact Insert-Retrievable Chokes

35% smaller, 45% lighterAchieve total vertical access for insert retrieval.

-

Subsea Ledeen Actuators

Control and actuation of subsea valvesChoose from double-acting or spring-return designs for shallow or deep water.

-

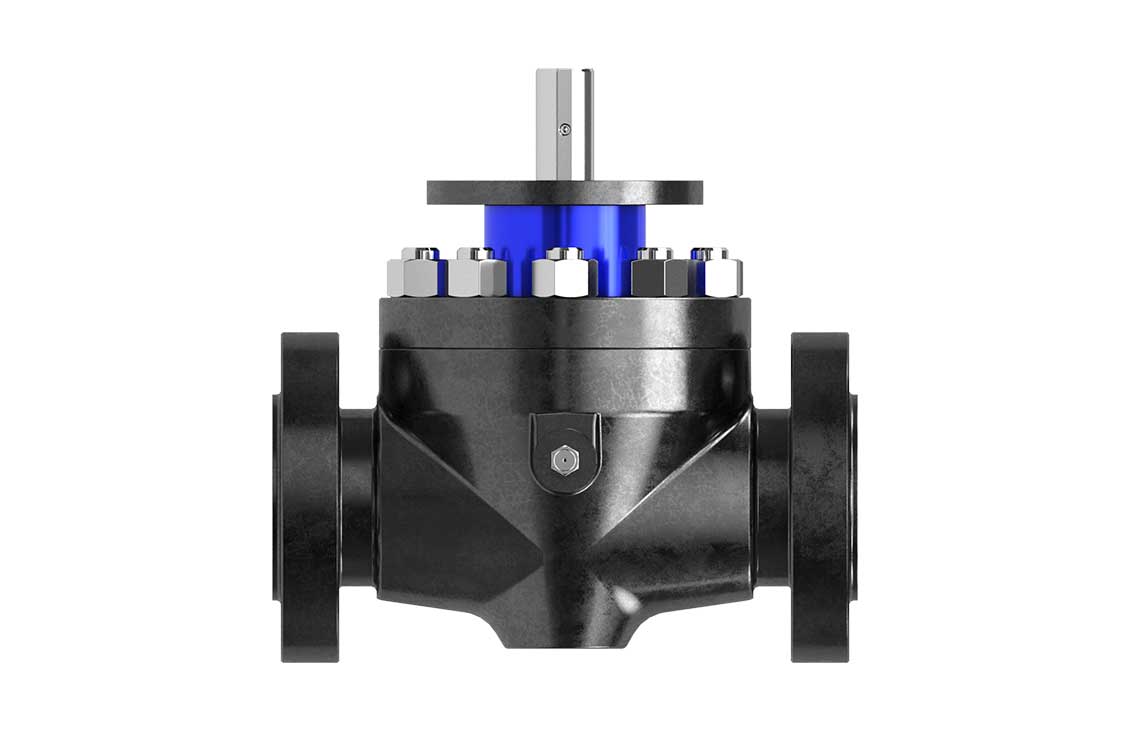

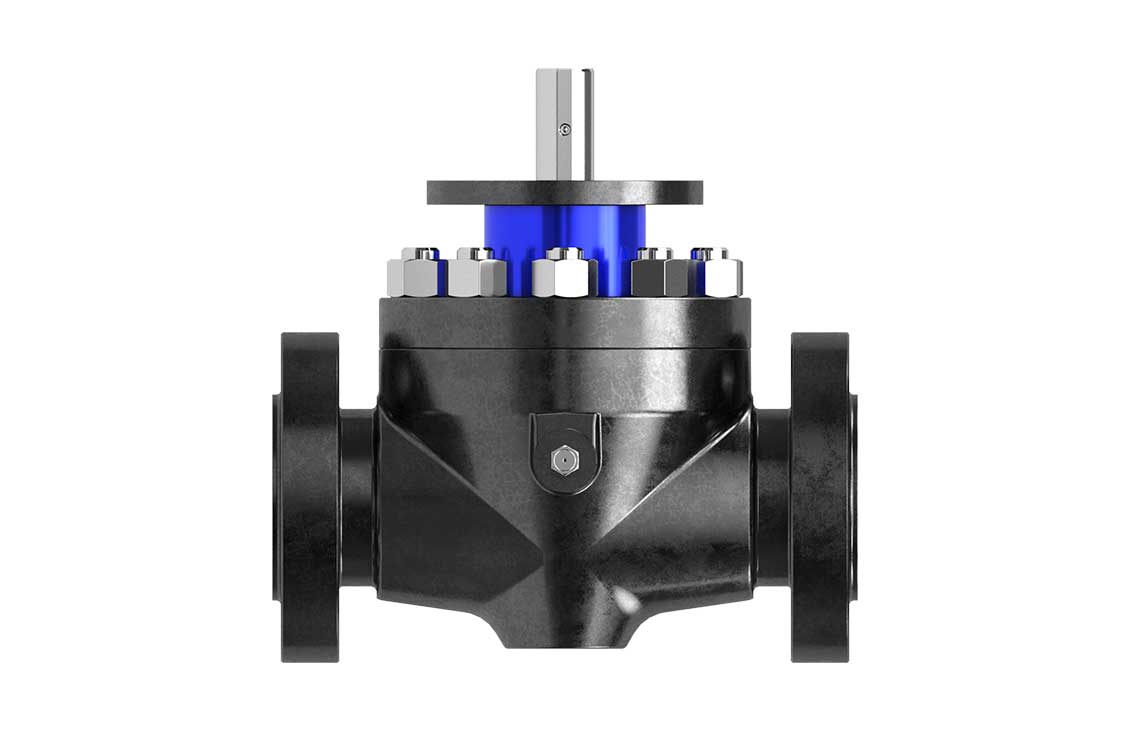

Cameron T30 Series

Fully welded ball valveLower emissions while improving uptime and profitability.

-

Tom Wheatley Swing Check Valve

API Spec 6D–compliant, fullbore pipeline check valve for demanding environmentsField-proven backflow prevention.

-

Subsea Gear Operators

Active and passive pressure compensationWithstand high pressures at deepwater depths with Maxtorque subsea worm gears.

-

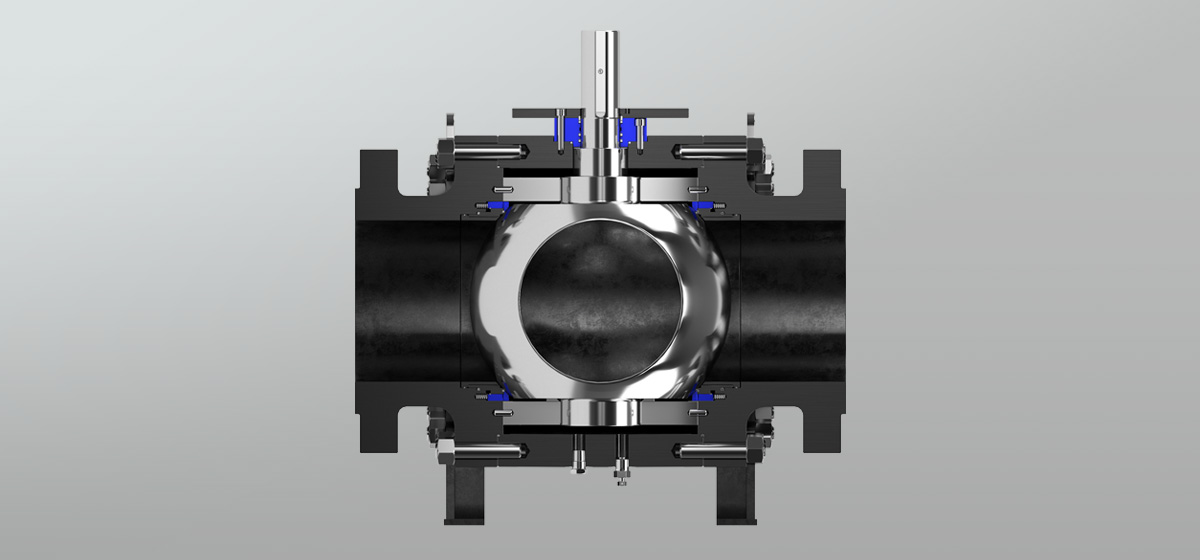

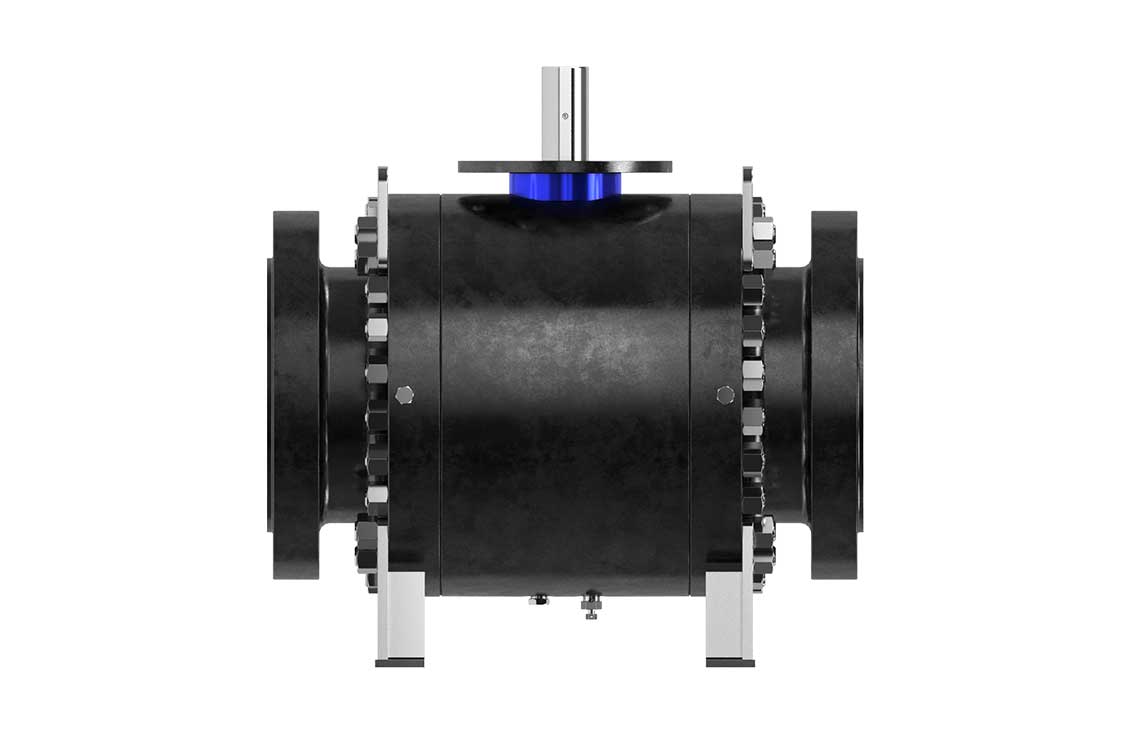

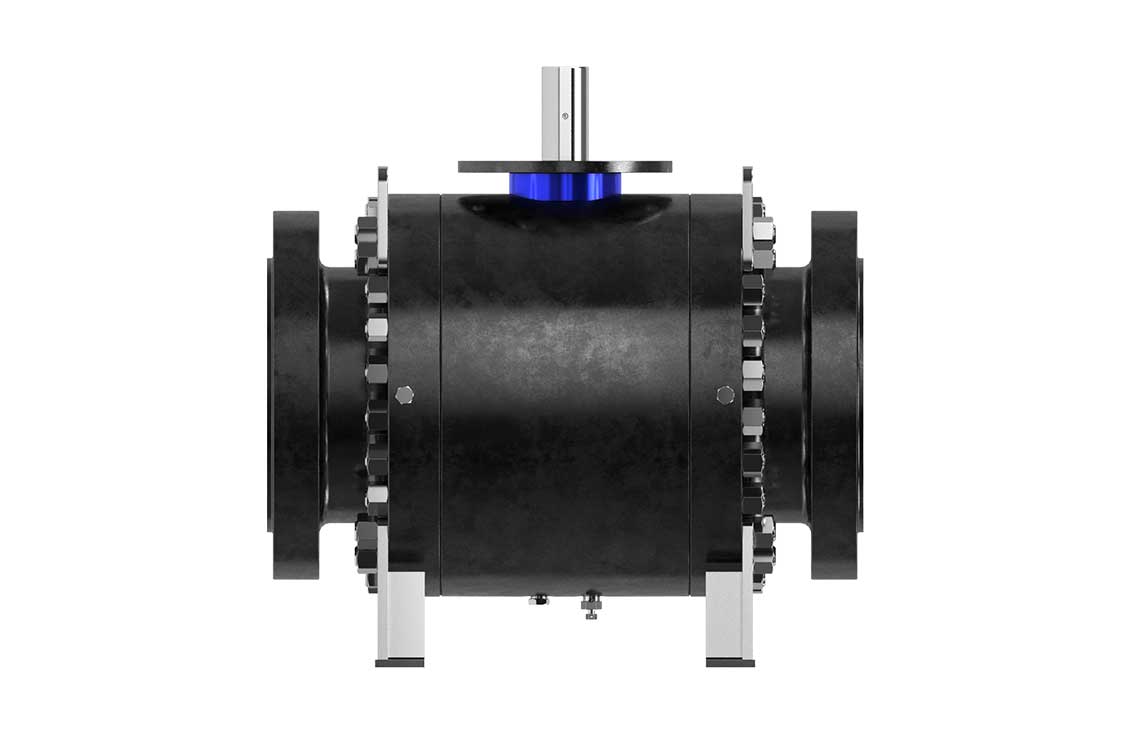

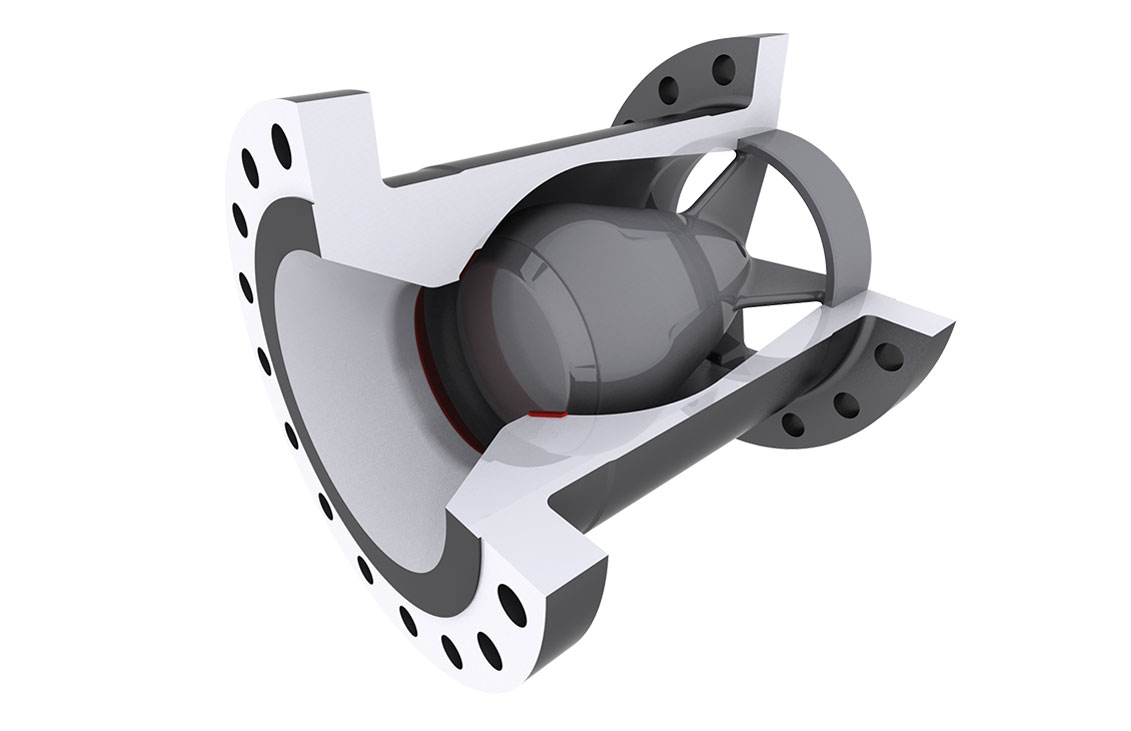

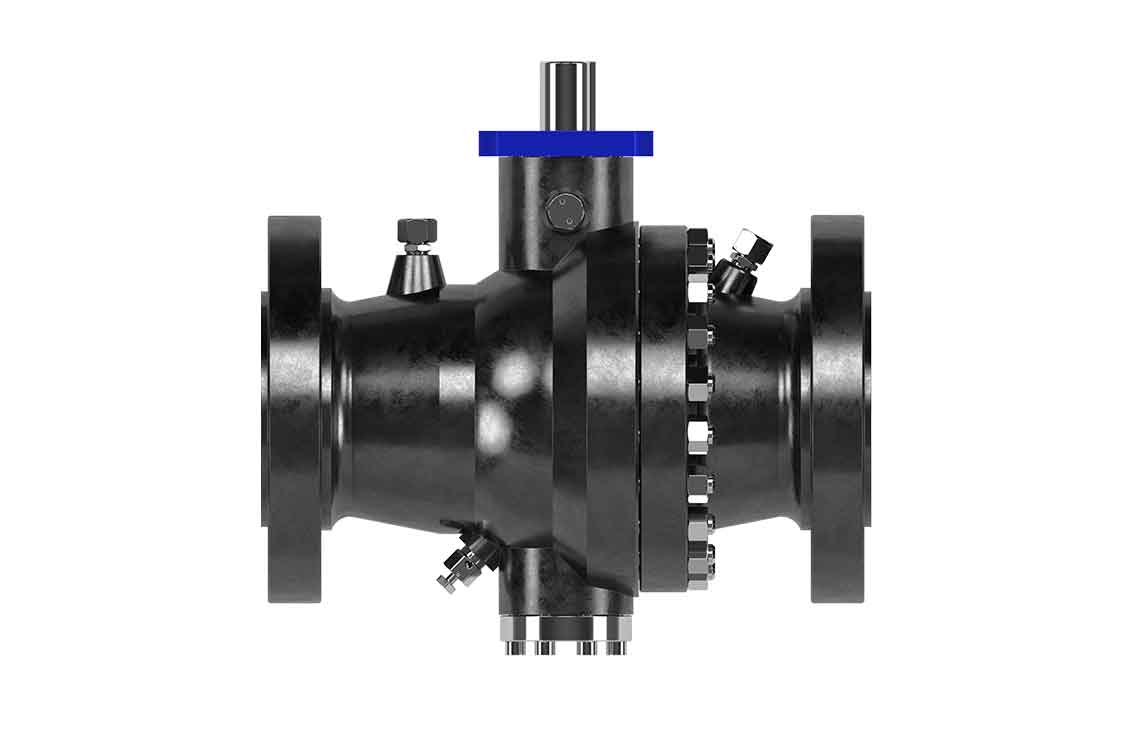

Grove B5

Trunnion-mounted, side-entry ball valveSizes: 6–64+ in; Classes: ANSI 150–1500

-

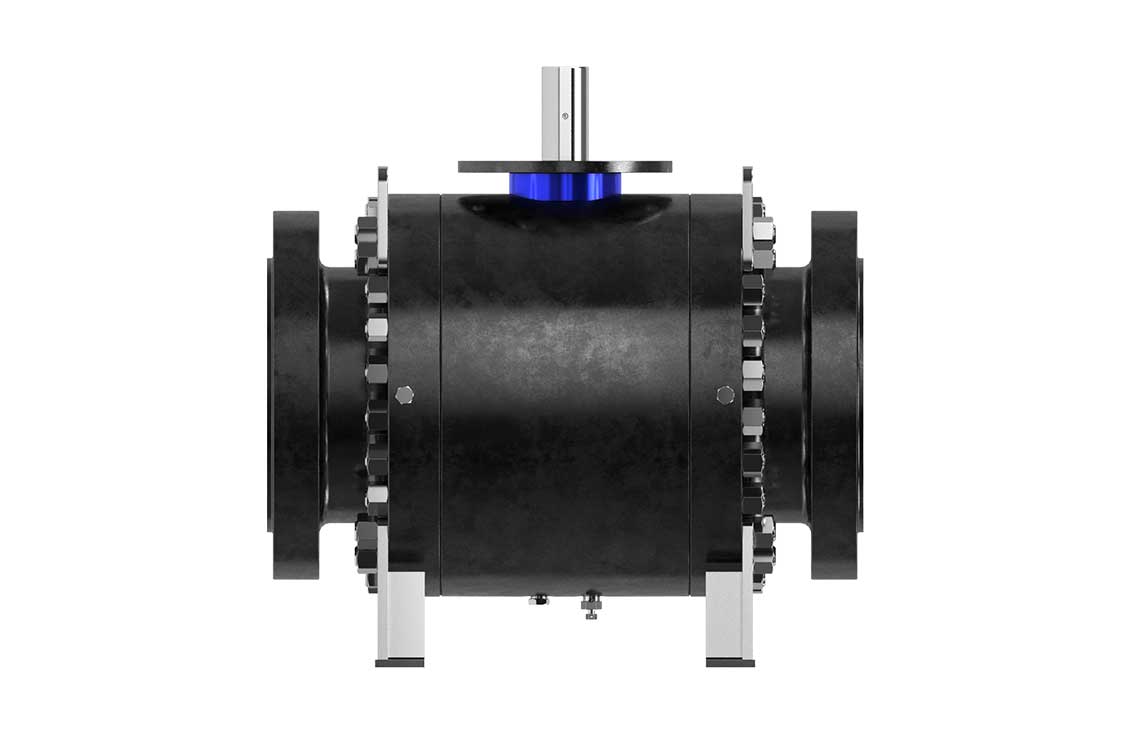

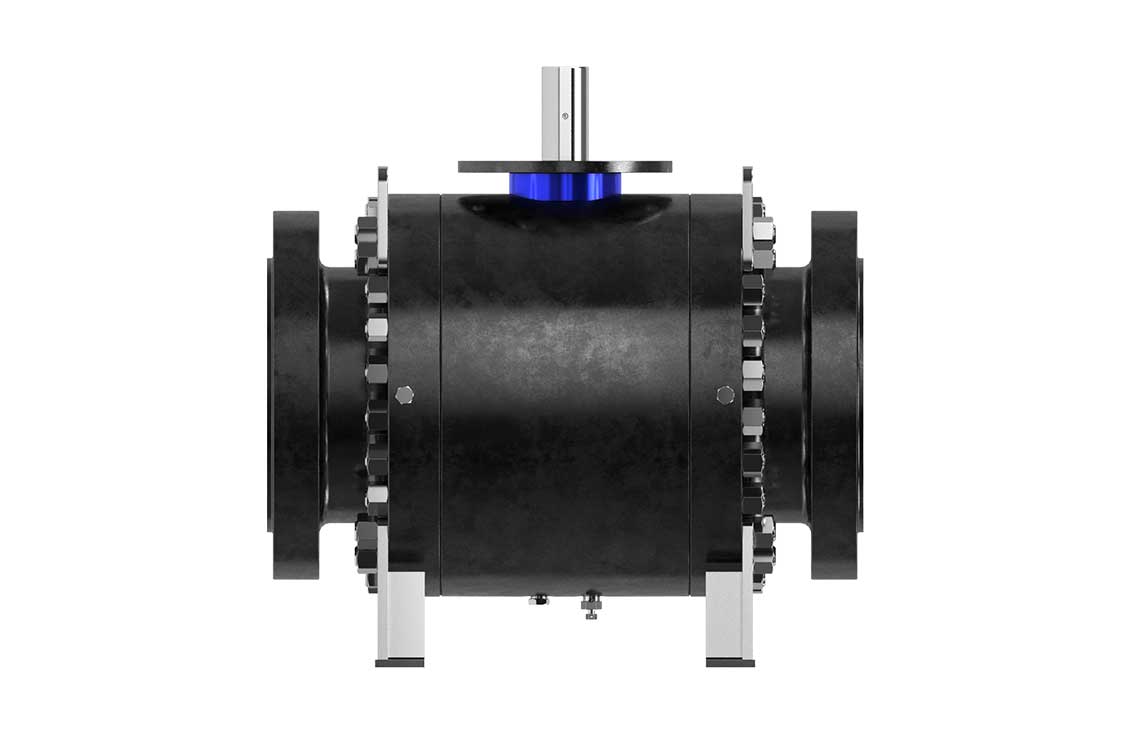

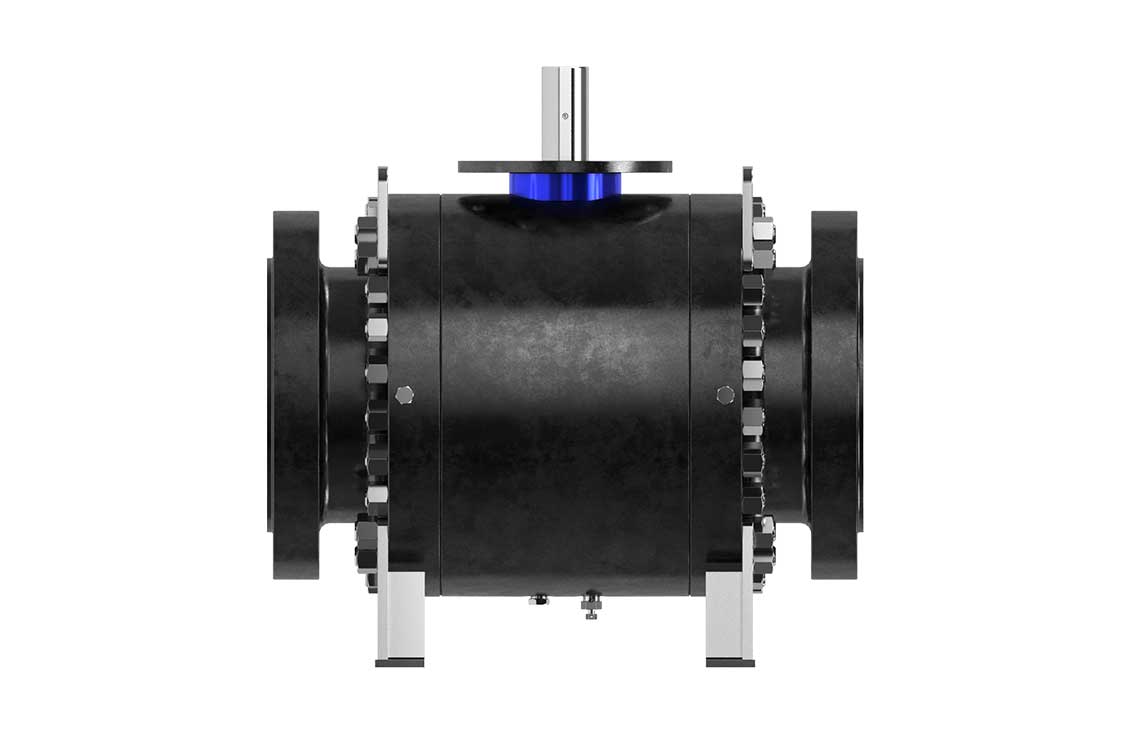

Grove B8

Fully welded ball valve2- to 60-in sizes, ANSI 150 to 2500.

-

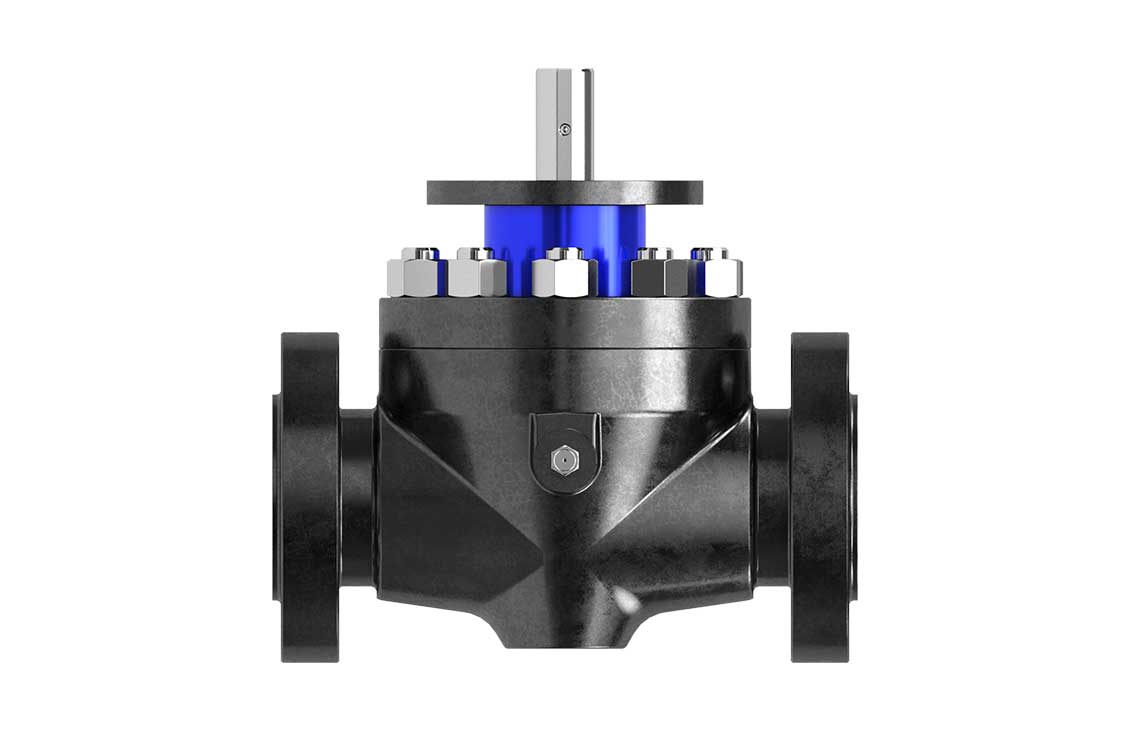

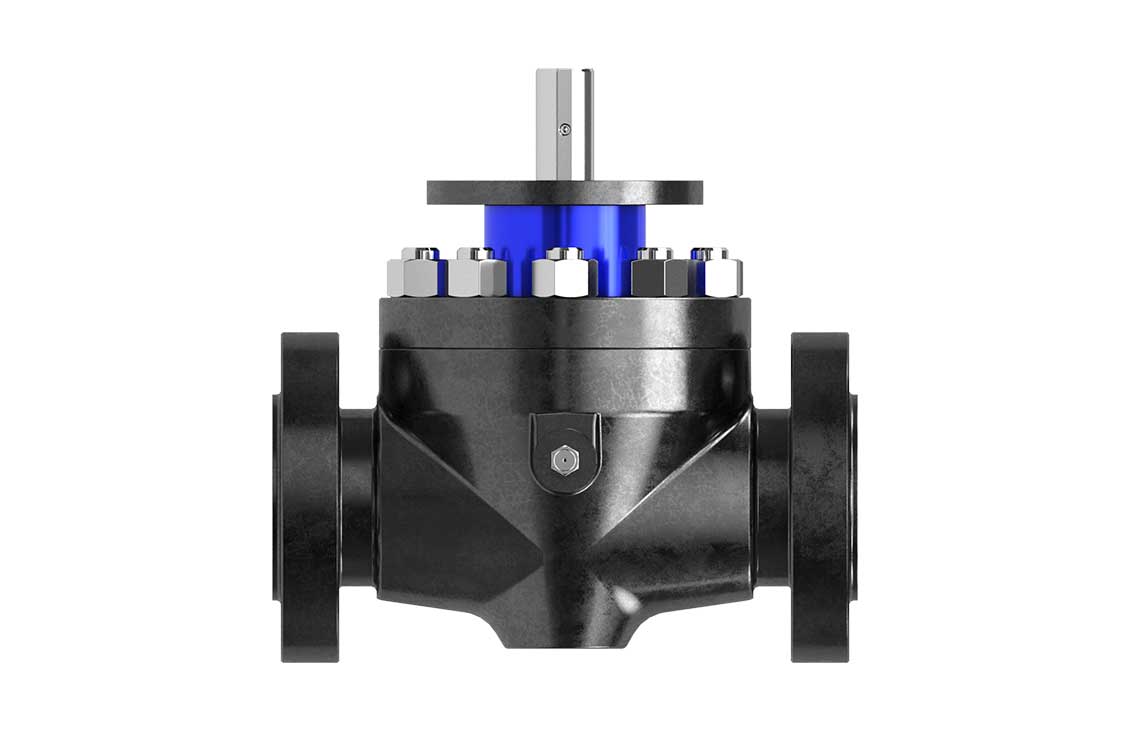

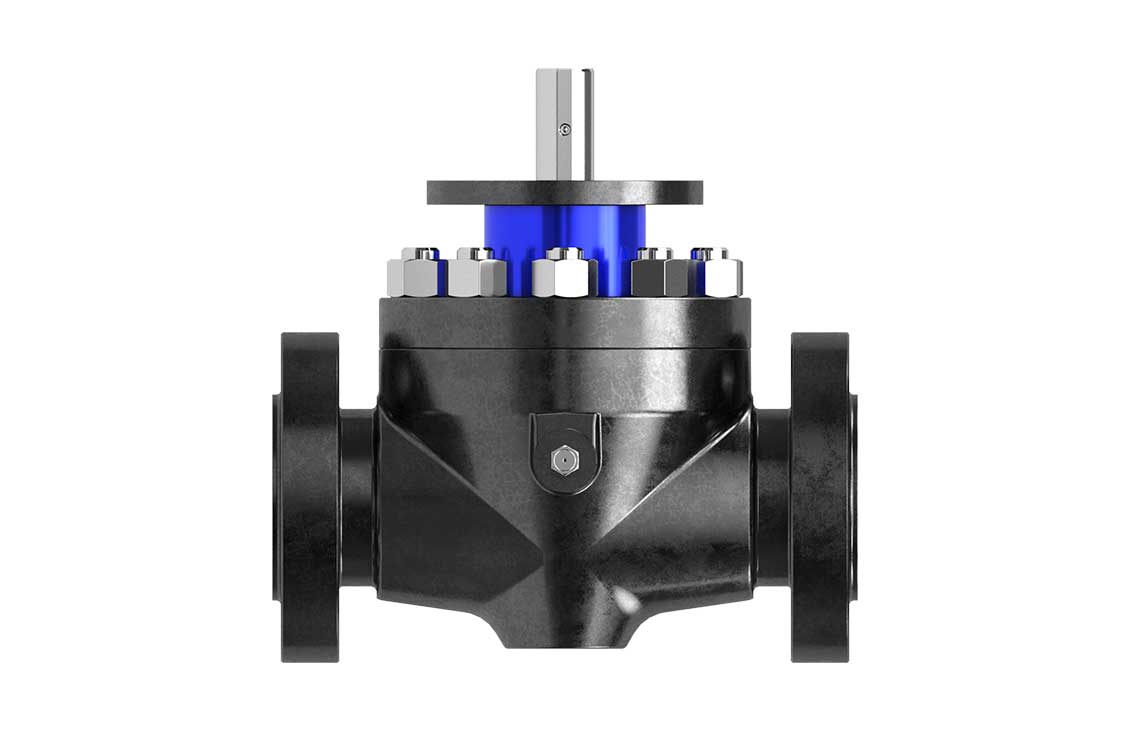

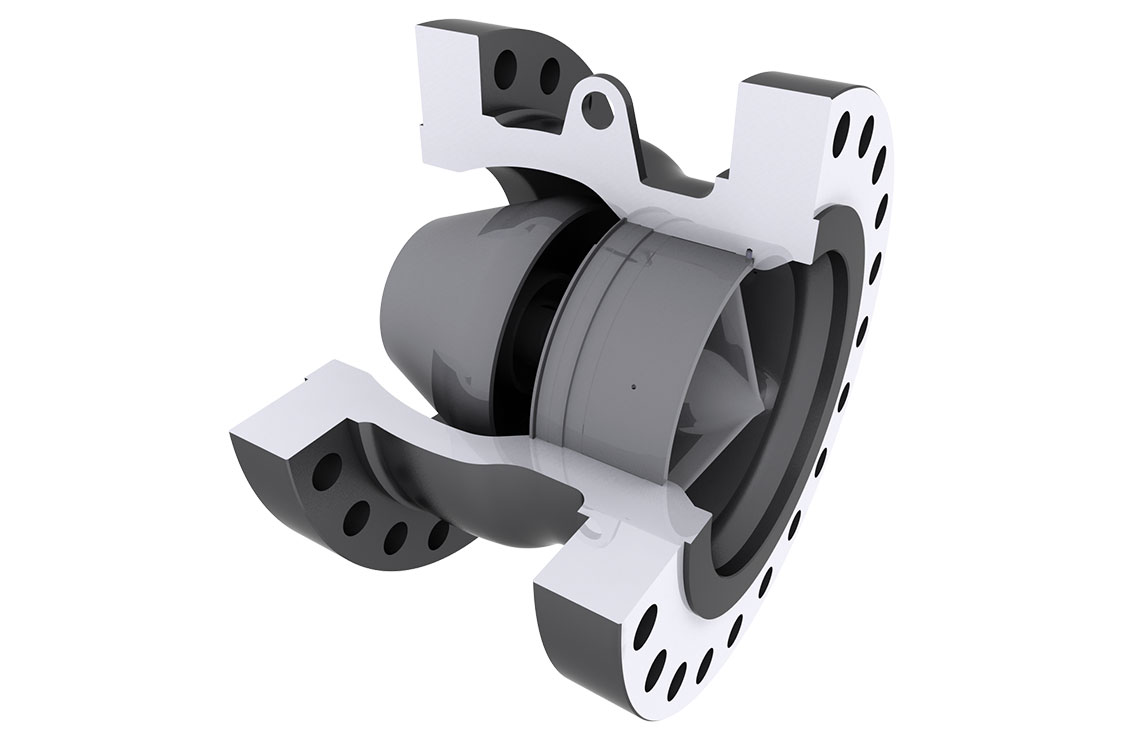

Grove BT2

Top-entry ball valve1 1/2- to 60-in sizes, ANSI 150 to 2500.

-

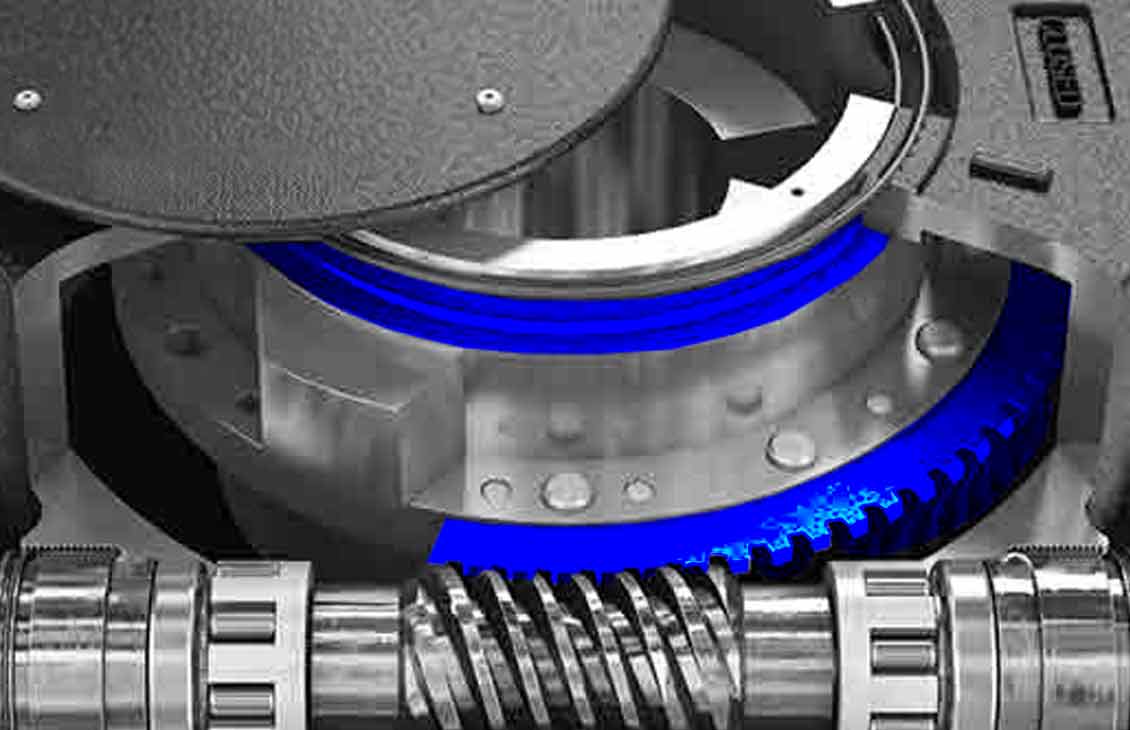

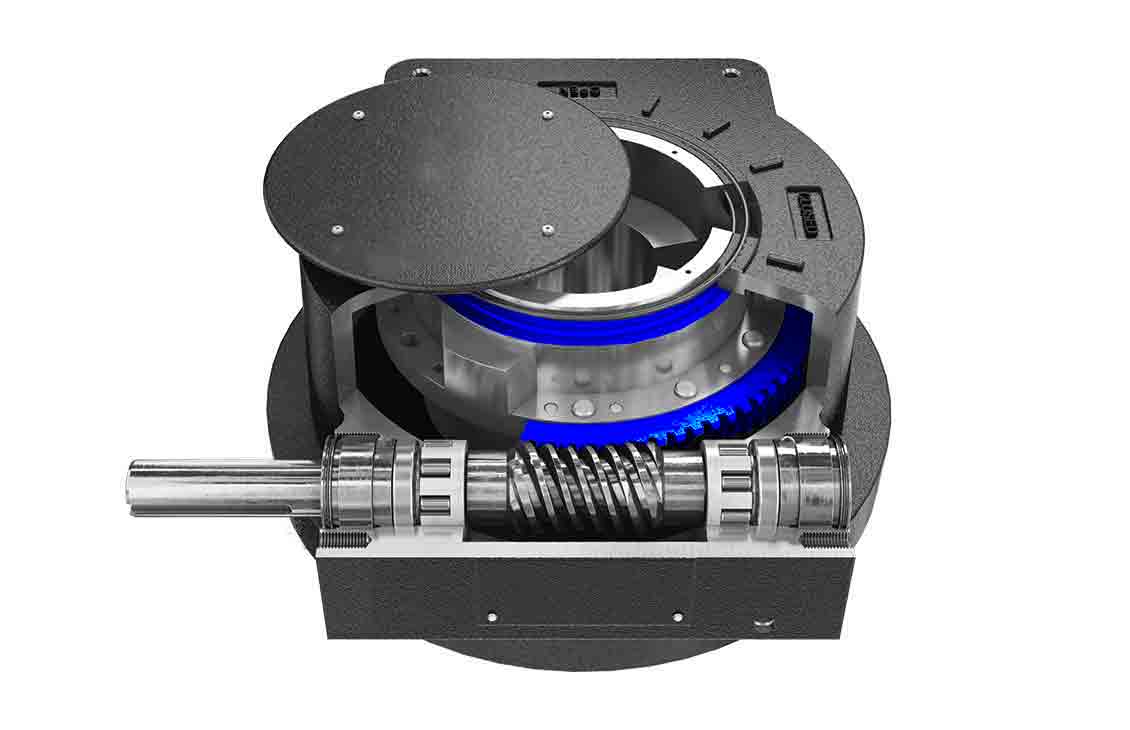

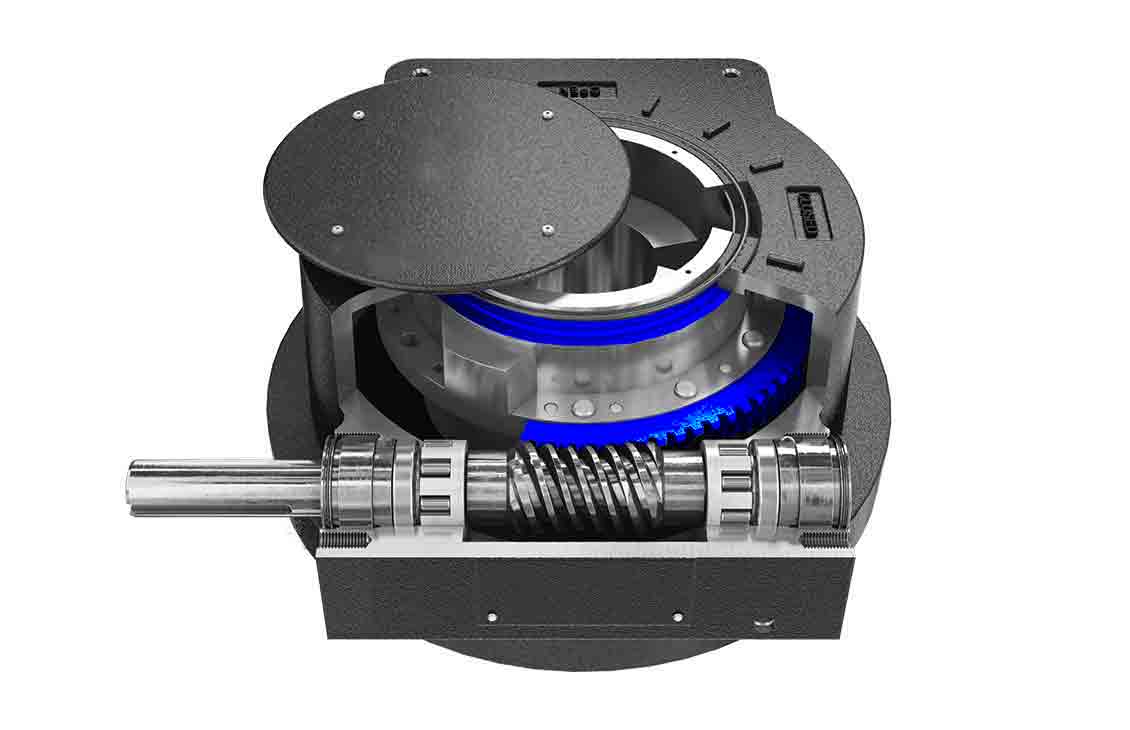

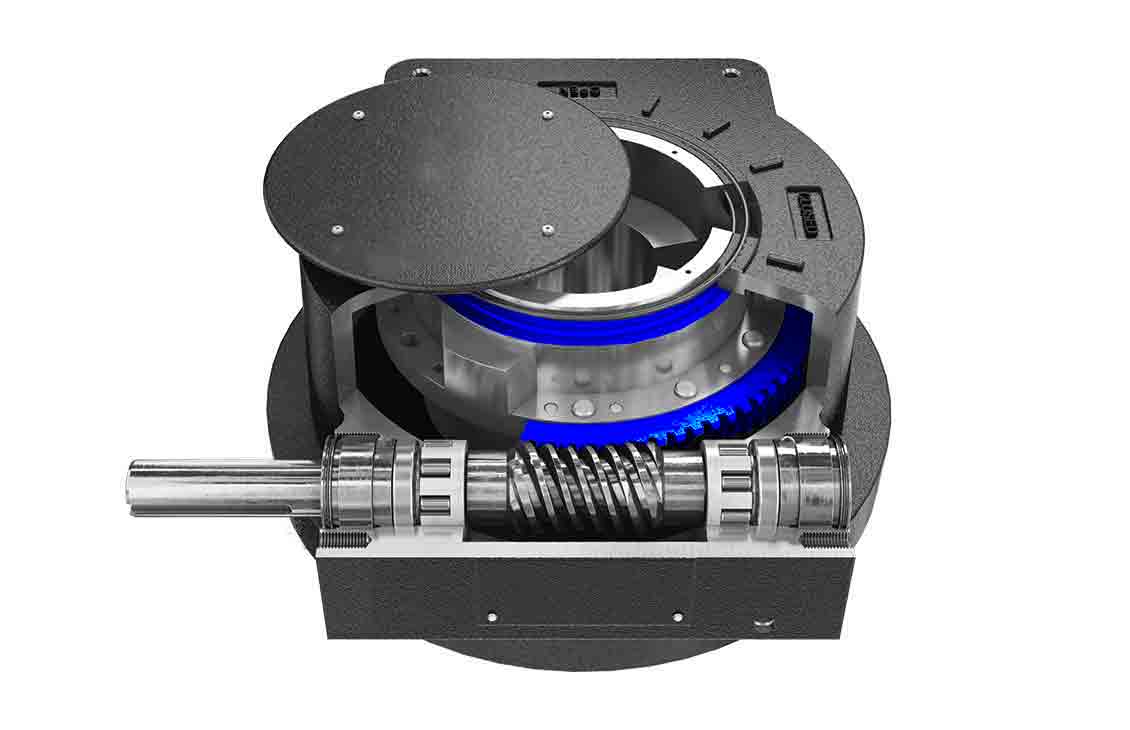

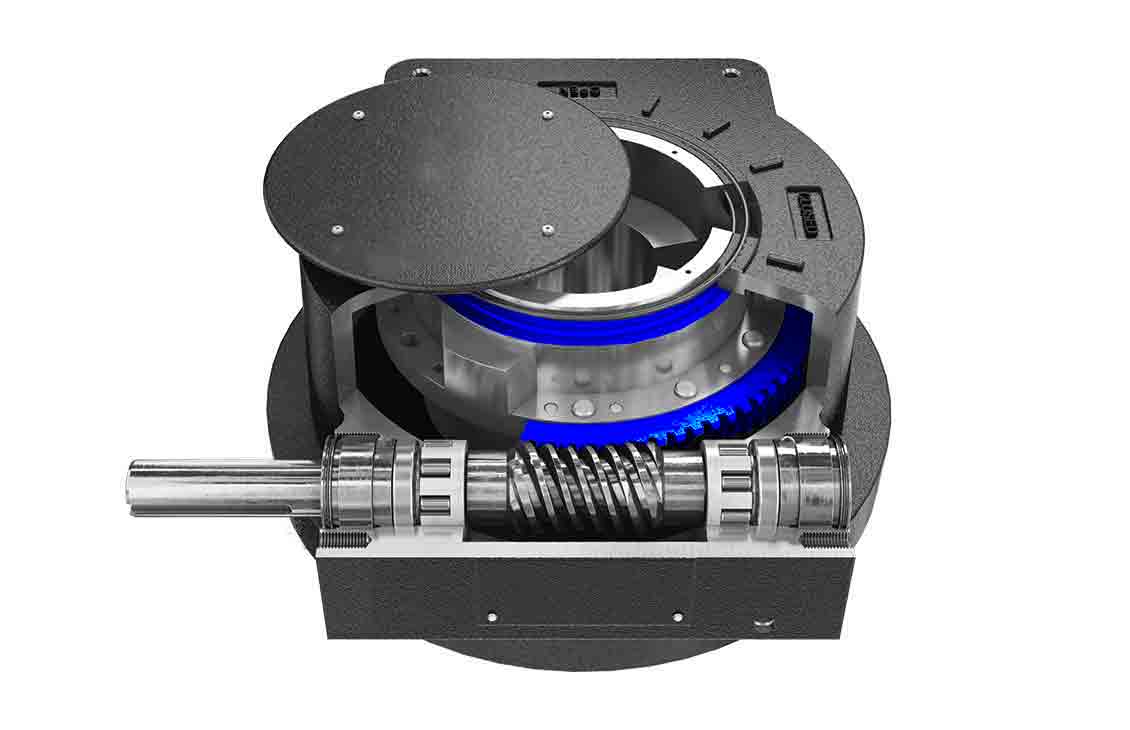

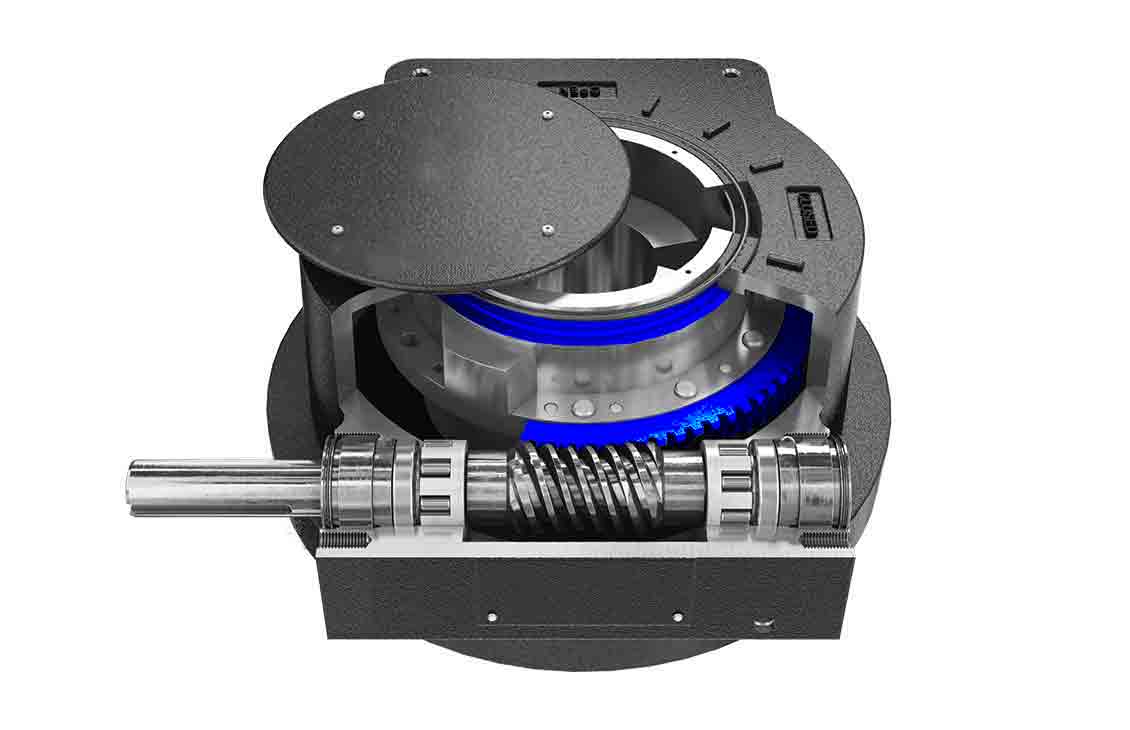

Maxtorque

High-performance worm gearsWorm-gear solutions that minimize effort.

Drilling

Land and offshore drilling applications

-

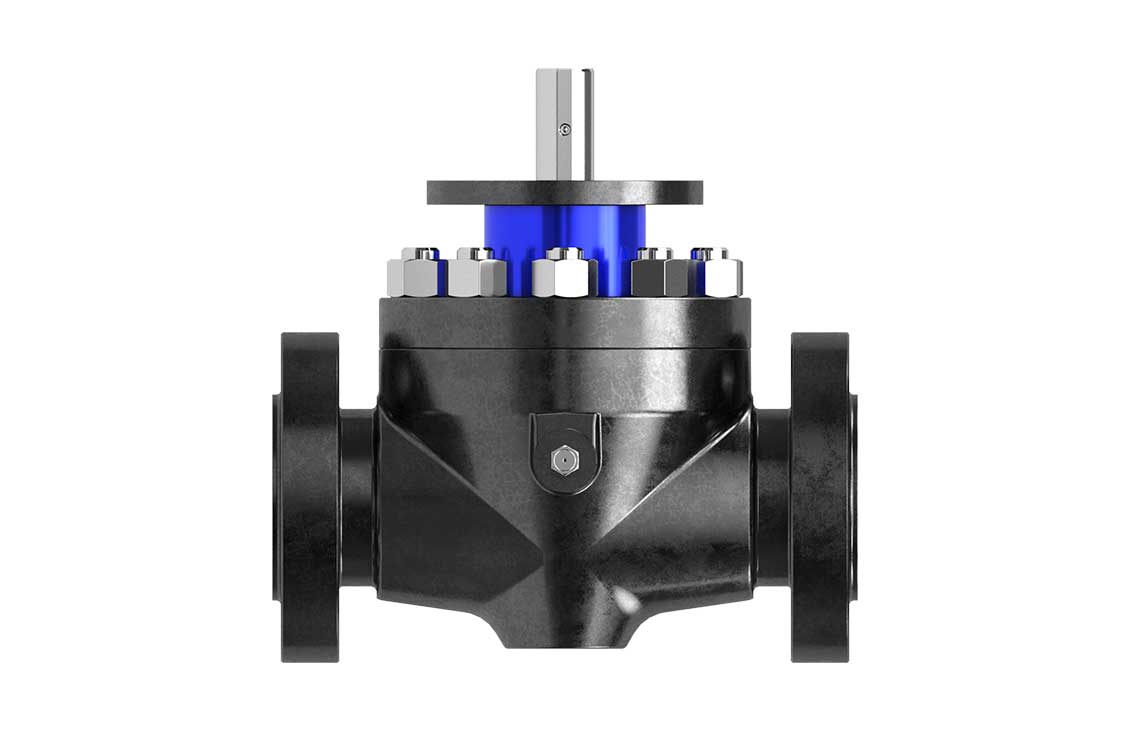

Series DM Demco

Gate valvesPremier gate valves providing reliable performance and extended service life in abrasive drilling applications.

-

Demco

Butterfly valvesDurable, lightweight, and ideal for a wide range of applications where space is at a premium.

-

DEMCO DT and DB

Gate ValvesOptimize operations in corrosive CO2 injection and waterflood applications.

-

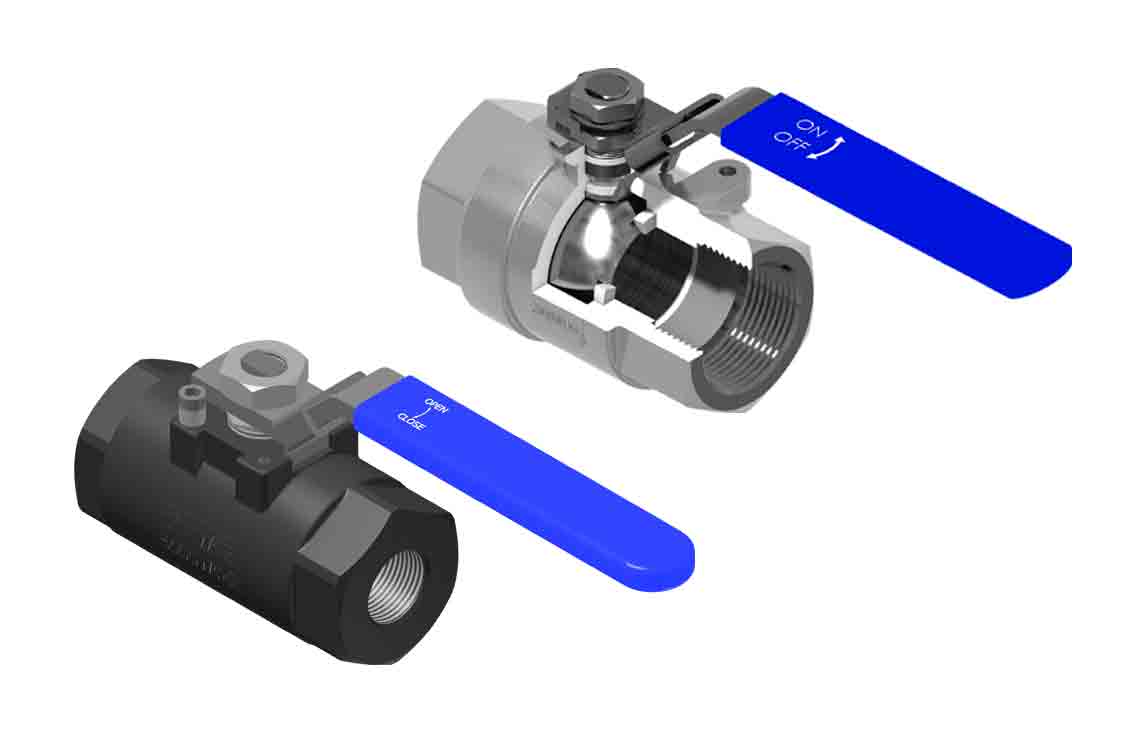

Navco

Floating ball valvesEconomical ball valves for general-purpose applications, featuring a wide range of styles and end connections.

Critical-service production

Corrosive and HPHT environments

-

Grove B5

Trunnion-mounted, side-entry ball valveSizes: 6–64+ in; Classes: ANSI 150–1500

-

Grove B7

Side-entry ball valve1 1/2- to 20-in sizes, ANSI 2500.

-

Grove B8

Fully welded ball valve2- to 60-in sizes, ANSI 150 to 2500.

-

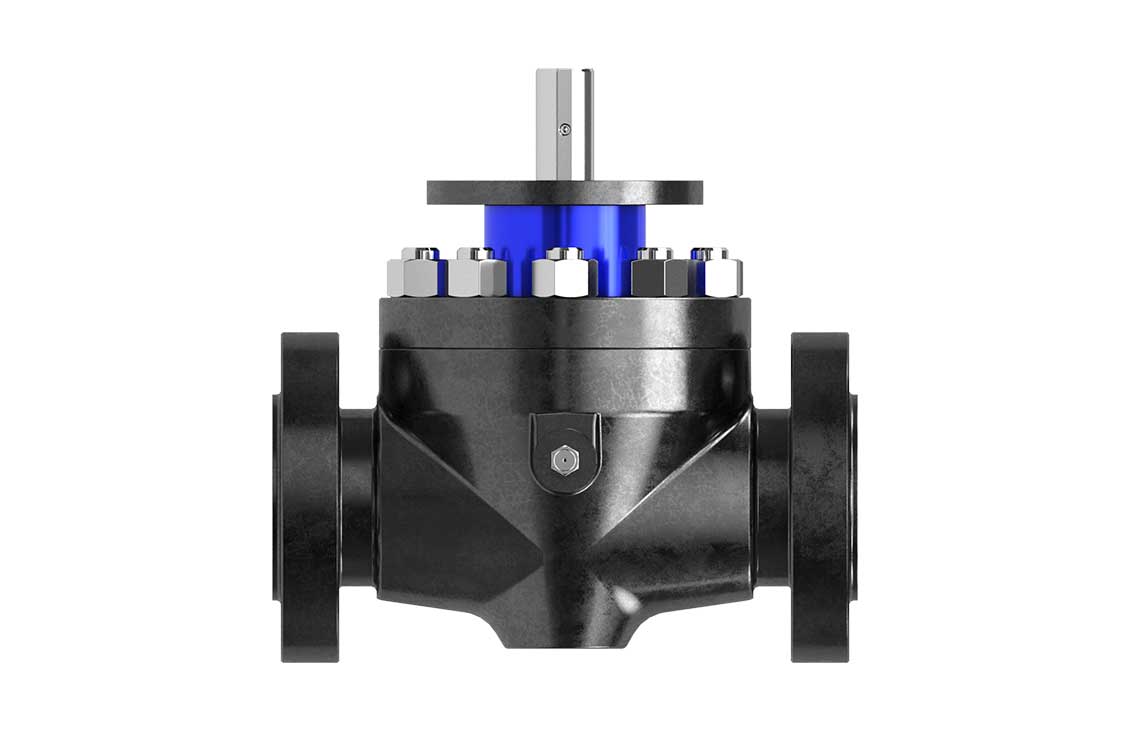

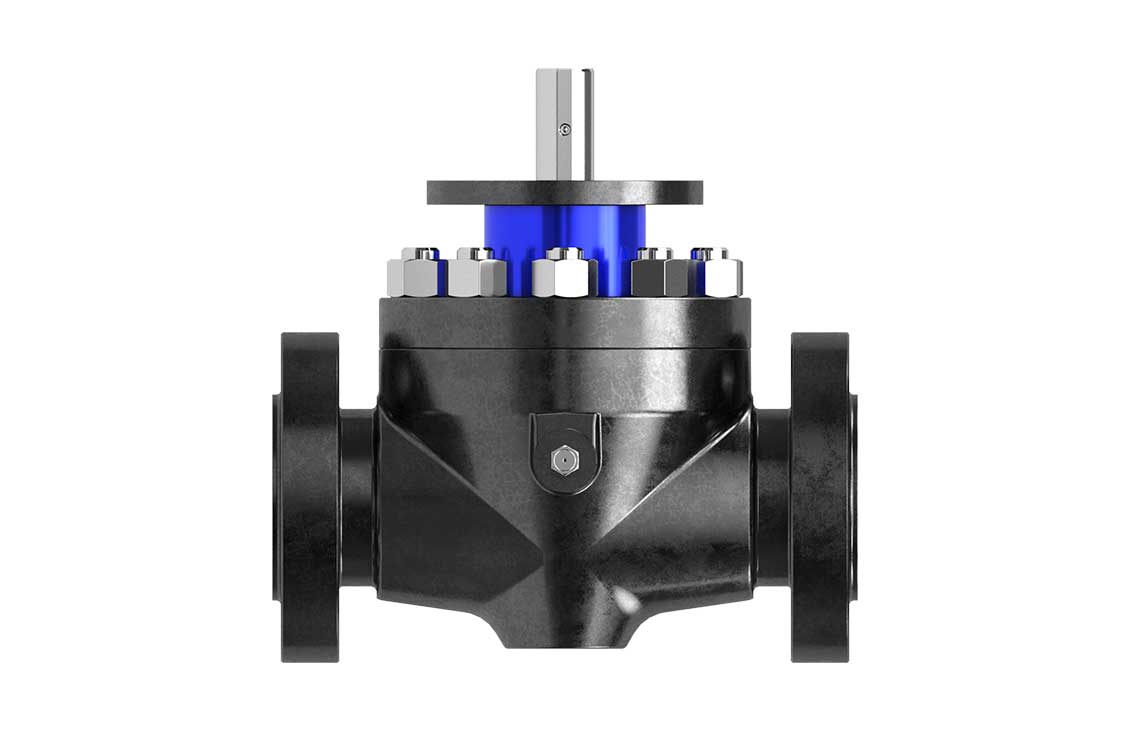

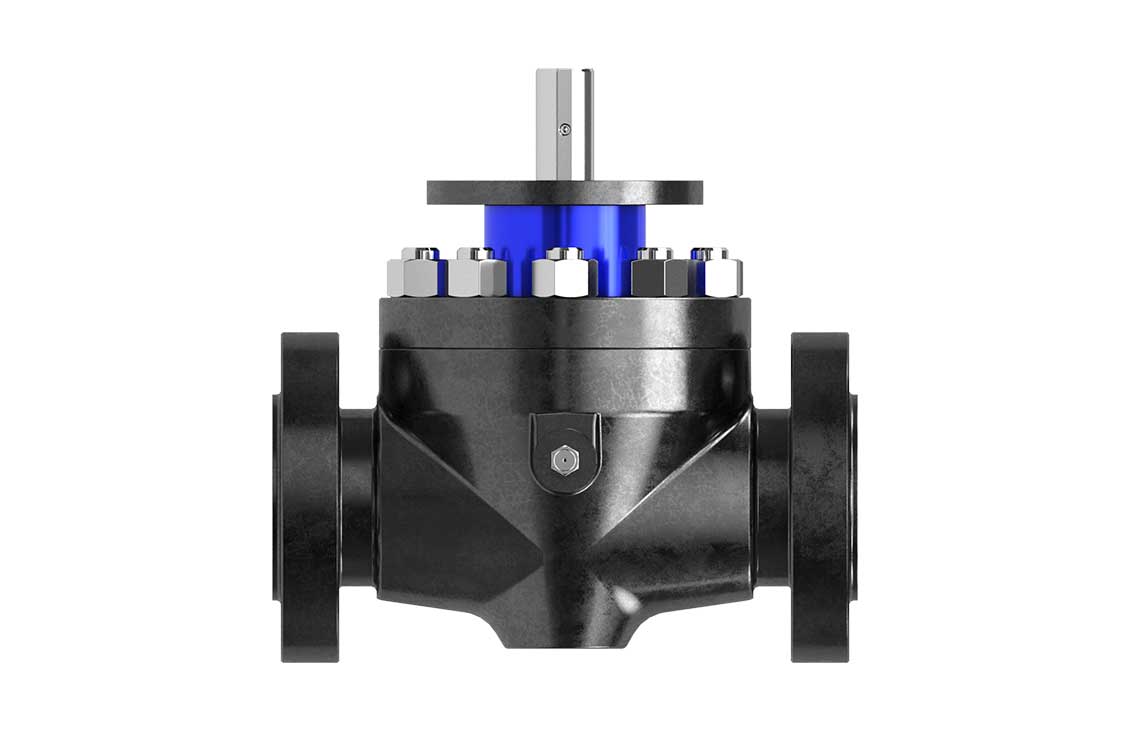

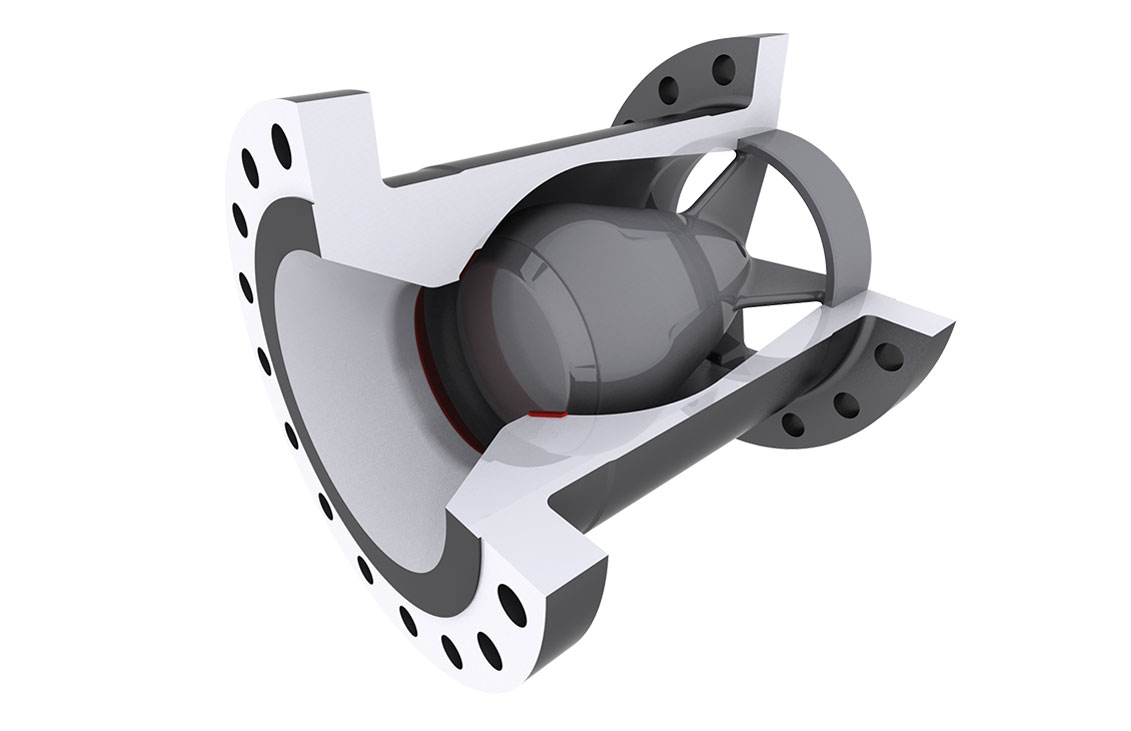

Grove BT1

Top-entry ball valve1/2- to 12-in sizes, ANSI 150 to 1500.

-

Grove BT2

Top-entry ball valve1 1/2- to 60-in sizes, ANSI 150 to 2500.

-

Grove B4

Trunnion-mounted, side-entry ball valve2- to 4-in sizes, ANSI 150 to 1500.

-

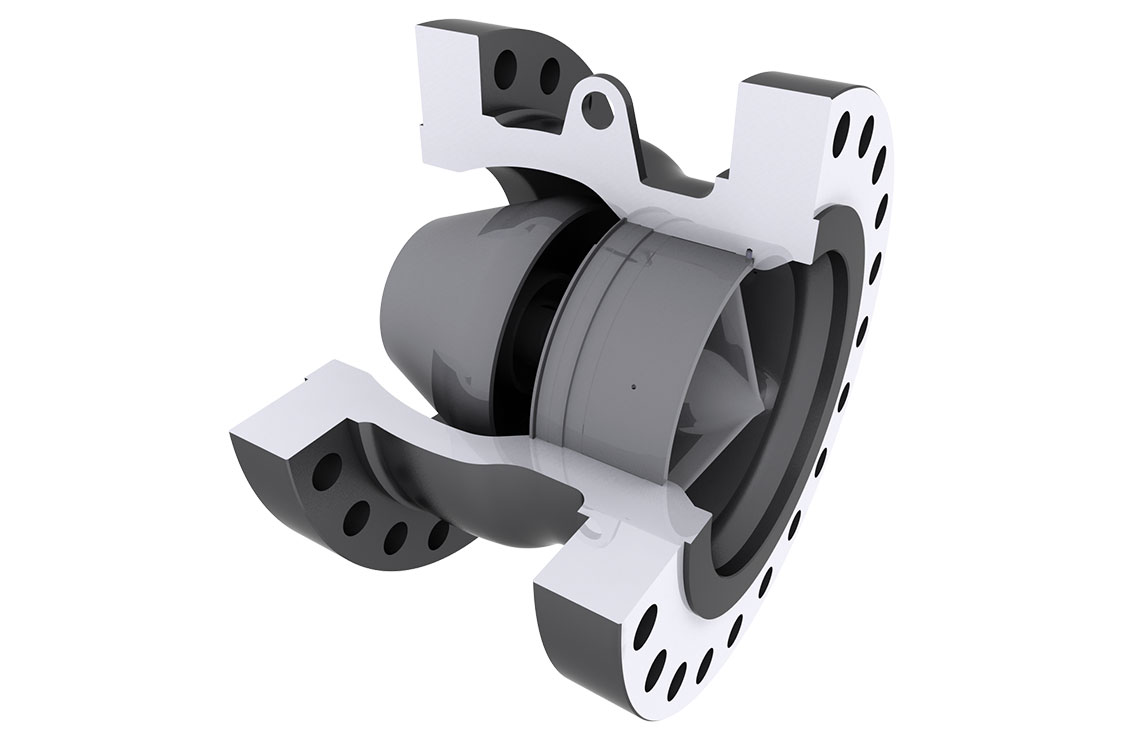

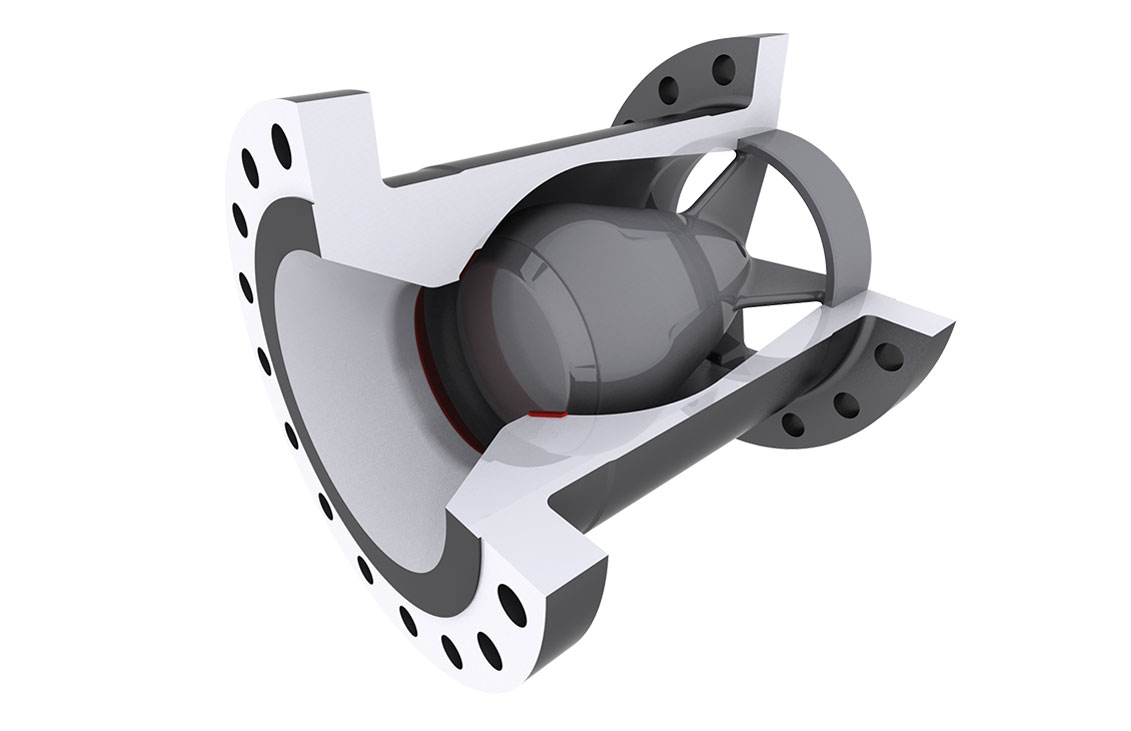

Grove IST

Integrated seat technology ball valveOvercome ball flexing to 10,000 psi.

-

ENTECH DRV-Z

Nozzle check valveSmall-bore valve designed for use in piping systems.

-

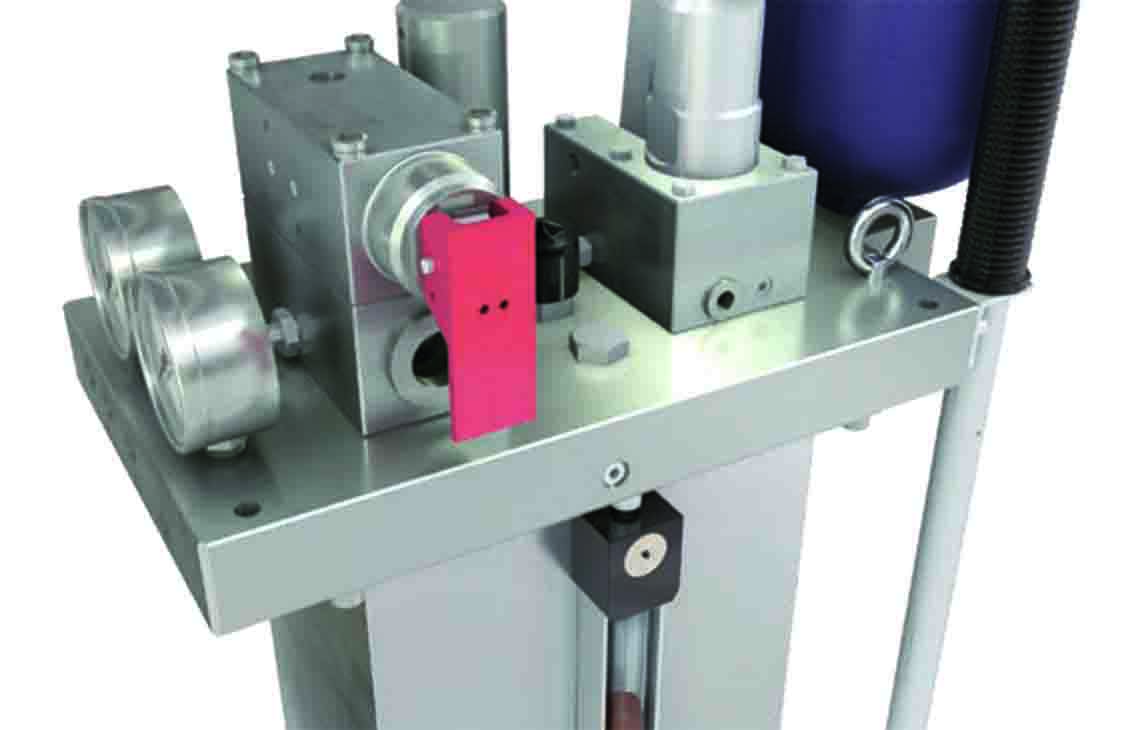

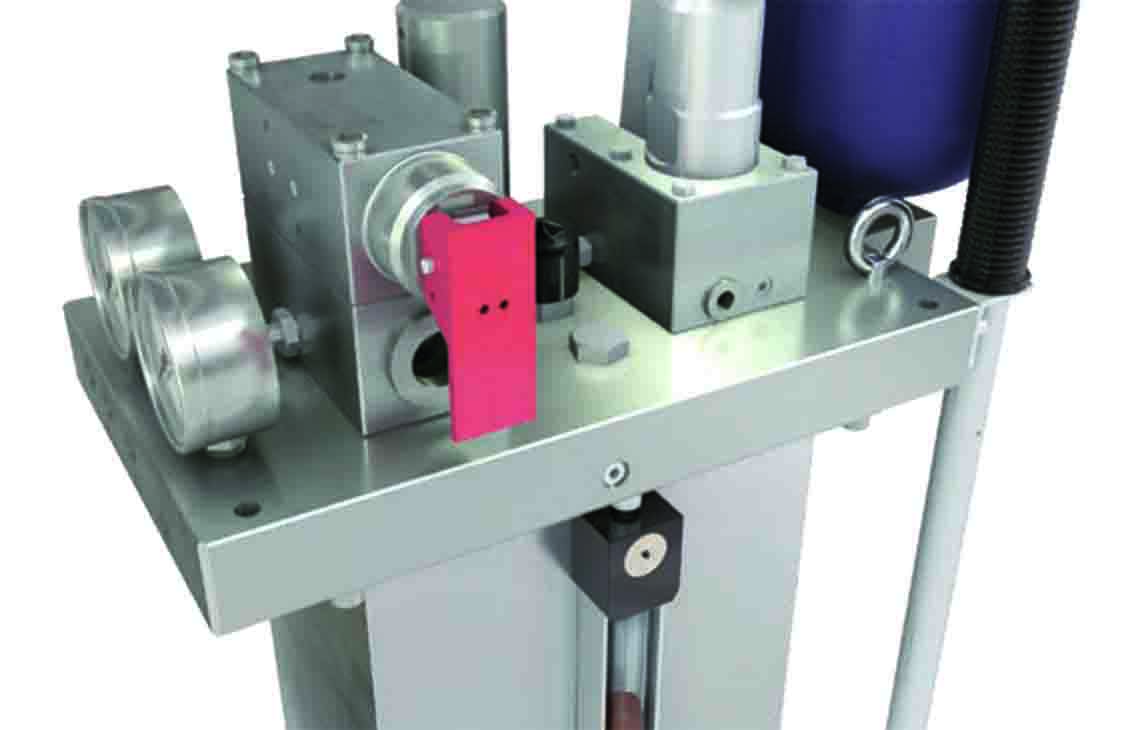

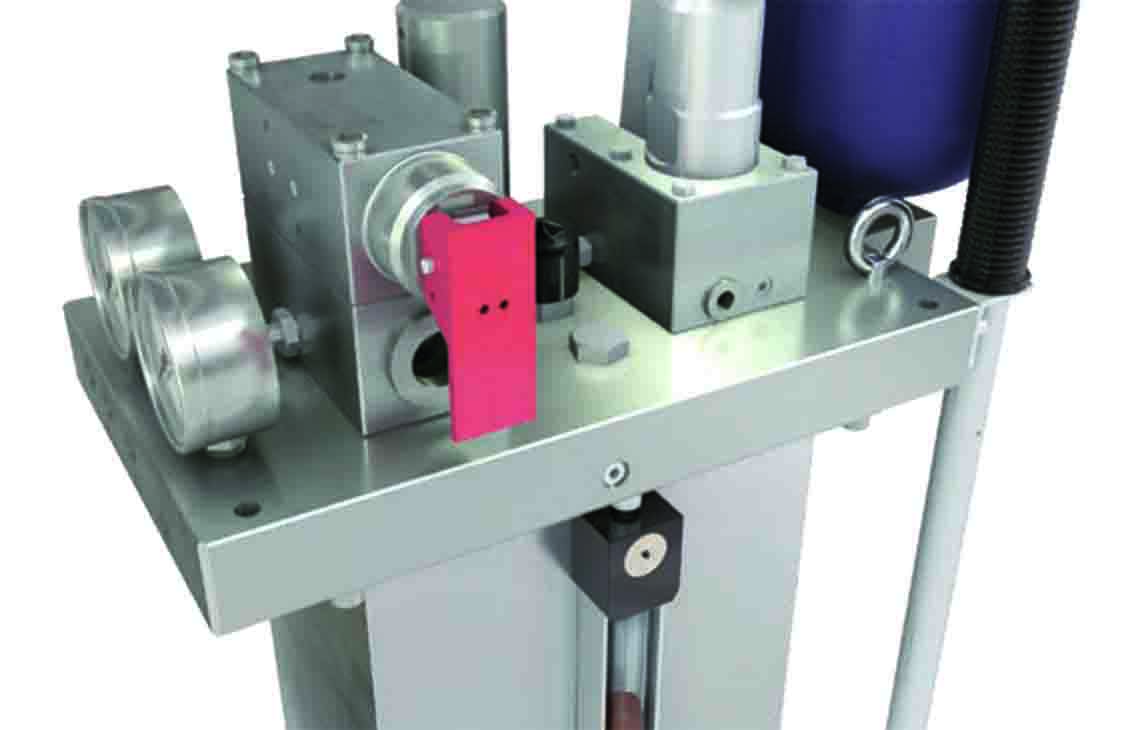

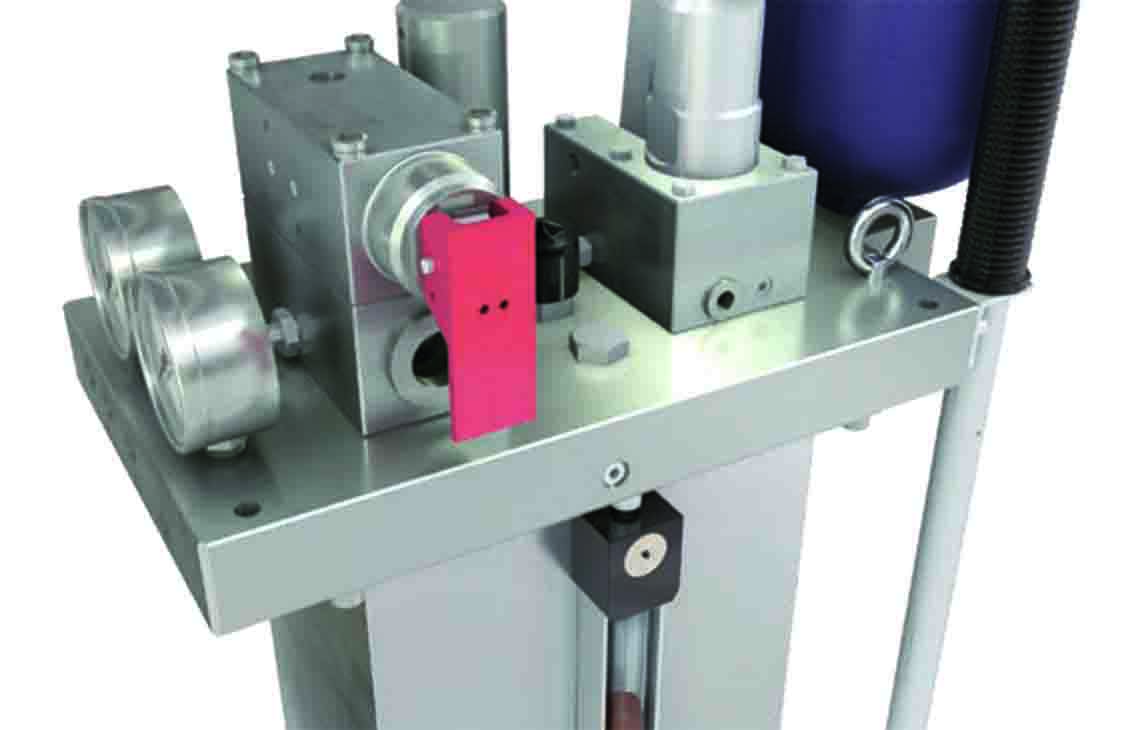

Compact Ledeen Actuators

Customer-focused solutionsSave valuable space with one of the smallest compact actuators on the market.

-

Hydraulic Ledeen Actuators

Quarter-turn operationAchieve on-off modulating control of multiple valve types.

-

Pneumatic Ledeen Actuators

Quarter-turn operationReliable performance with compressed air, natural gas, or nitrogen.

-

Ledeen SCCS

Self-contained control systemEnsure reliable valve shutdown when an external powersource is unavailable.

-

Subsea Ledeen Actuators

Control and actuation of subsea valvesChoose from double-acting or spring-return designs for shallow or deep water.

-

Maxtorque

High-performance worm gearsWorm-gear solutions that minimize effort.

-

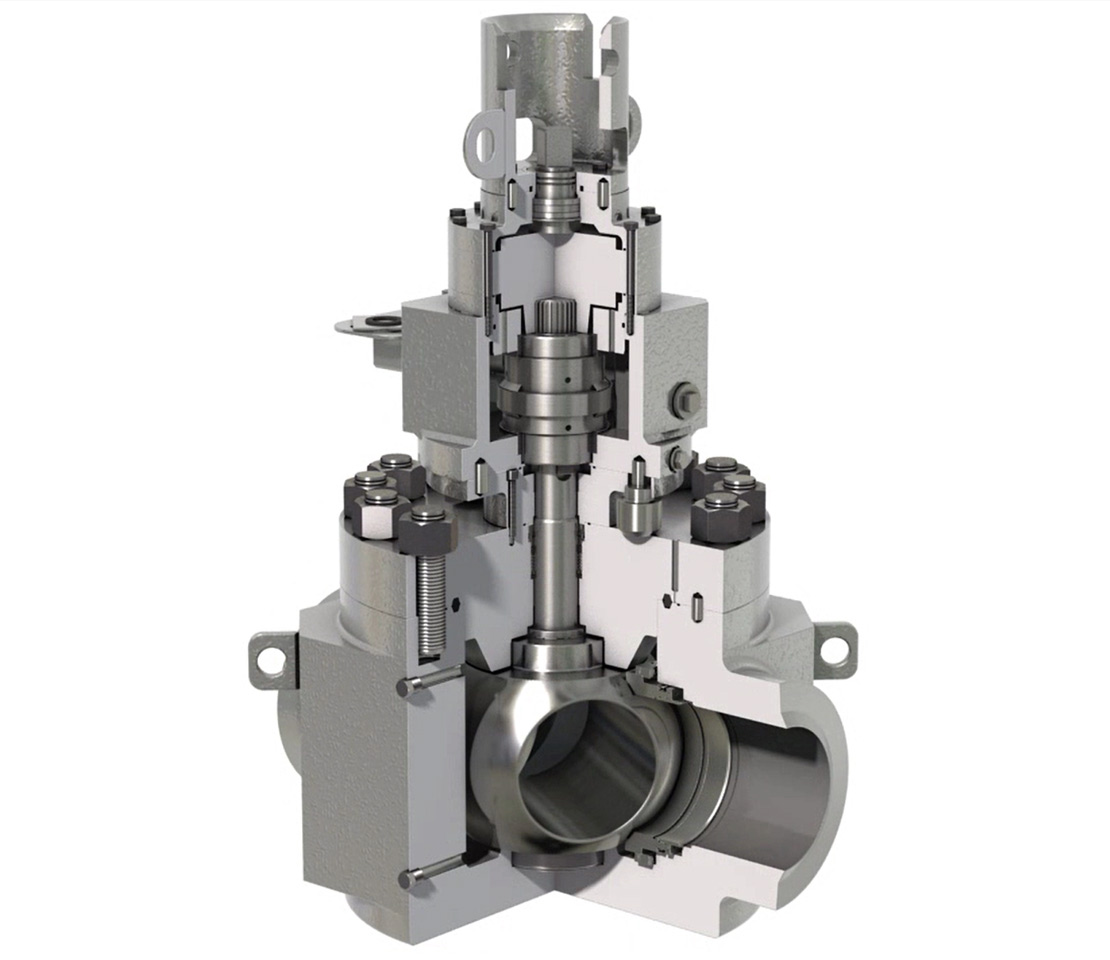

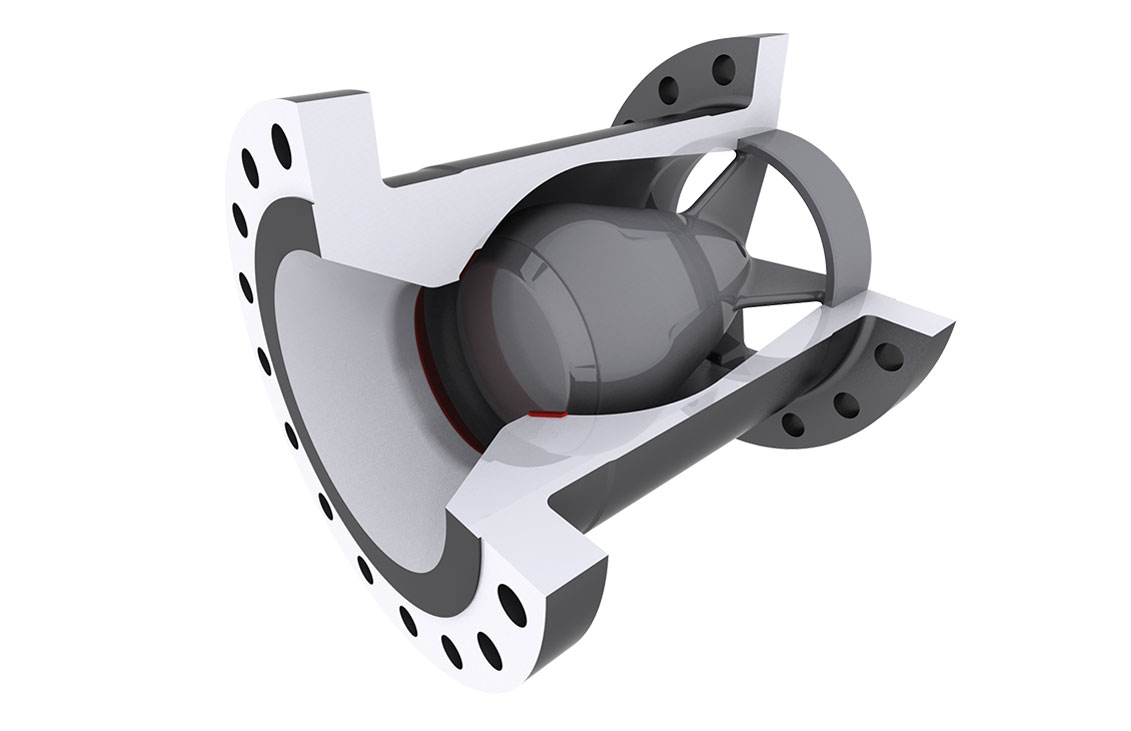

Orbit

Rising stem ball valveIdeal when zero leakage and frequent operation are required.

-

Super G

Texsteam plug valveDesigned for bubble-tight sealing and high resistance to corrosion, wear, and impact.

-

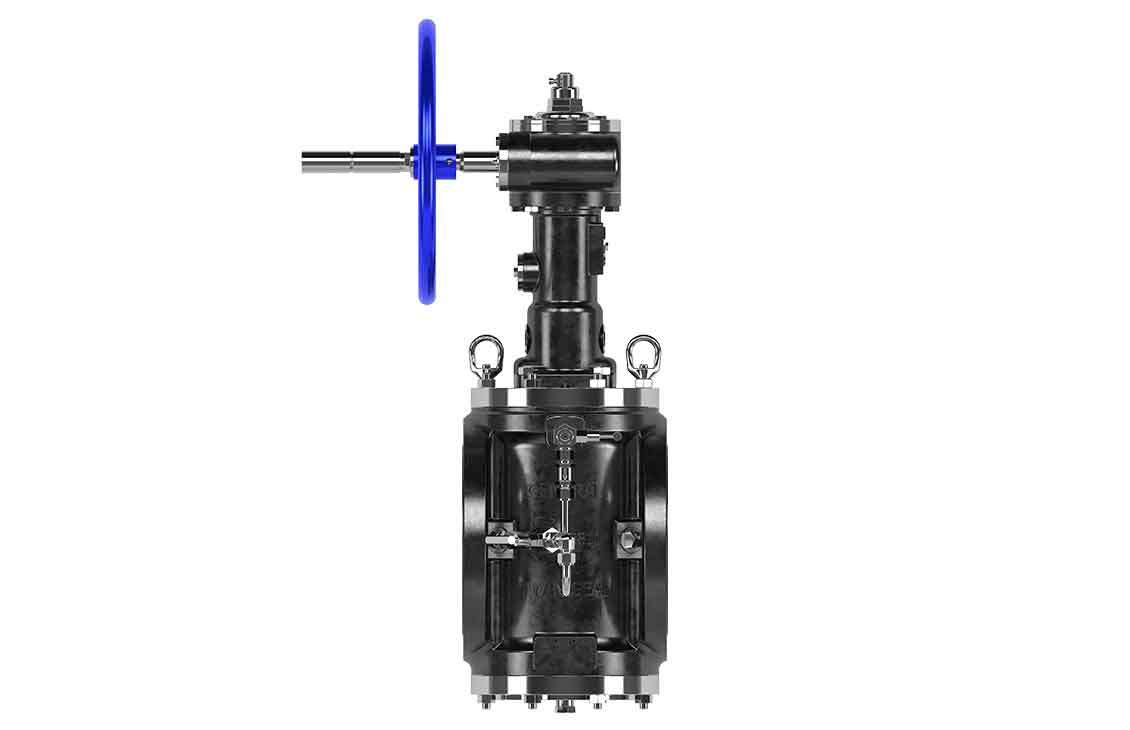

WKM Pow-R-Seal

Double expanding gate valveEnhanced safety and seal reliability.

Standard production

Separation, metering, tank battery, wastewater, and EOR

-

ENTECH DRV-Z

Nozzle check valveSmall-bore valve designed for use in piping systems.

-

Grove B4

Trunnion-mounted, side-entry ball valve2- to 4-in sizes, ANSI 150 to 1500.

-

Grove B5

Trunnion-mounted, side-entry ball valveSizes: 6–64+ in; Classes: ANSI 150–1500

-

Grove B7

Side-entry ball valve1 1/2- to 20-in sizes, ANSI 2500.

-

Grove B8

Fully welded ball valve2- to 60-in sizes, ANSI 150 to 2500.

-

Grove BT1

Top-entry ball valve1/2- to 12-in sizes, ANSI 150 to 1500.

-

Grove BT2

Top-entry ball valve1 1/2- to 60-in sizes, ANSI 150 to 2500.

-

Hydraulic Ledeen Actuators

Quarter-turn operationAchieve on-off modulating control of multiple valve types.

-

Pneumatic Ledeen Actuators

Quarter-turn operationReliable performance with compressed air, natural gas, or nitrogen.

-

Ledeen SCCS

Self-contained control systemEnsure reliable valve shutdown when an external powersource is unavailable.

-

Maxtorque

High-performance worm gearsWorm-gear solutions that minimize effort.

-

Rising Stem Applications

High-ratio, small-envelope, robustSee our MAXTORQUE products for rising stem applications.

-

Super G

Texsteam plug valveDesigned for bubble-tight sealing and high resistance to corrosion, wear, and impact.

-

WKM 370D Series

Trunnion-mounted ball valvesVariety of ANSI and API Spec 6D designs.

-

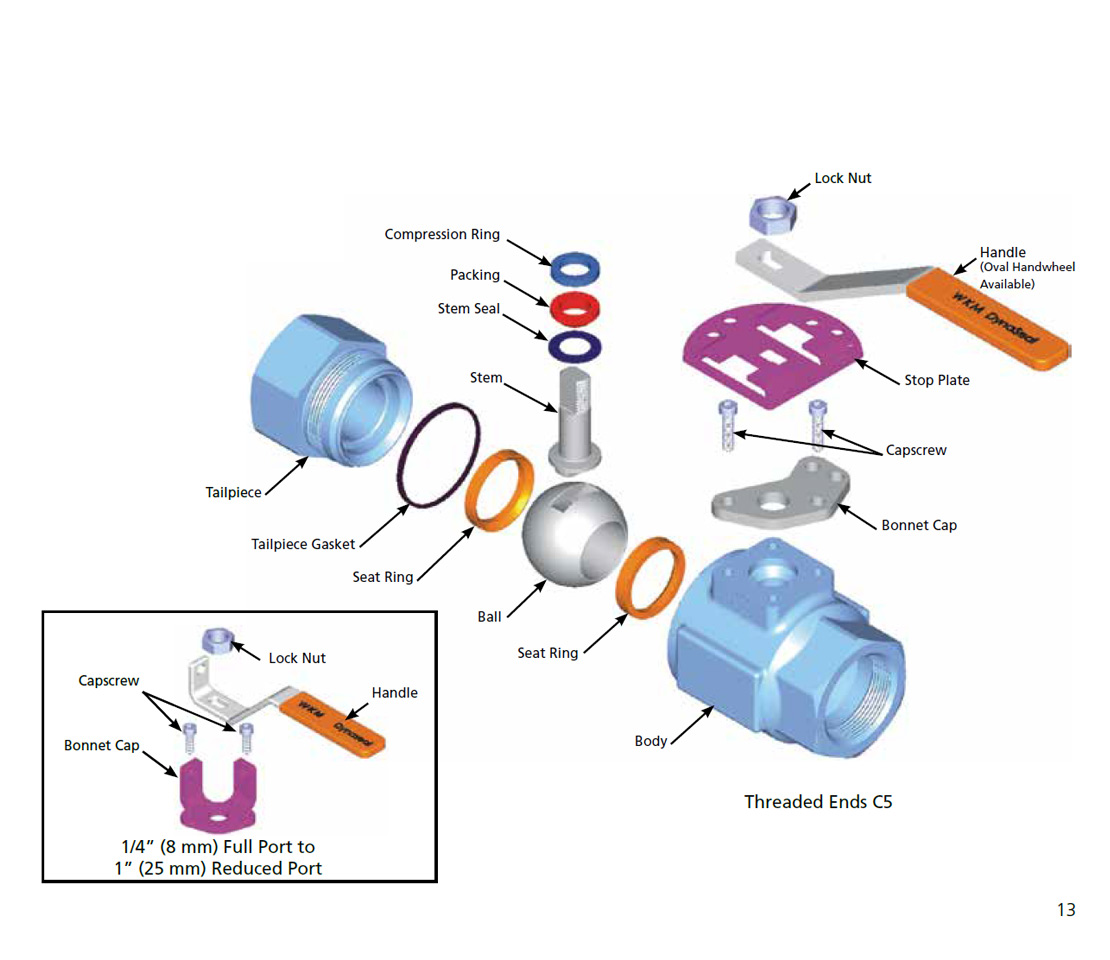

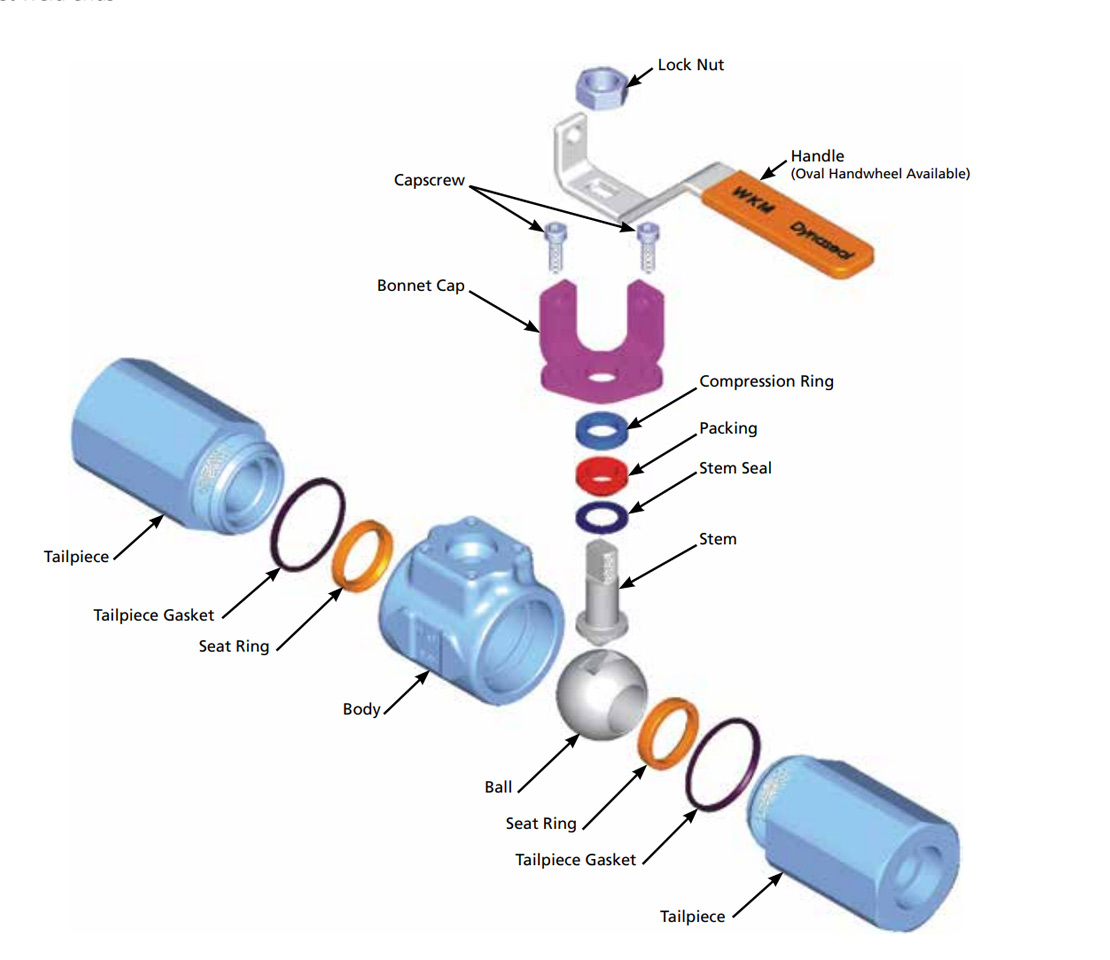

WKM 310C5

Floating ball valveProven performance in a wide range of oilfield, chemical, petrochemical, and hydrocarbon processing applications.

-

WKM Model 310F

Floating ball valvesThe Cameron WKM Model 310F floating ball valve satisfies a wide range of applications.

-

WKM C50

Floating ball valvesTwo-piece threaded end valve, fire tested and certified to API Spec 607.

-

WKM High-Performance Butterfly Valves

Double-offset butterfly valvesSealing performance of a ball or gate valve but in a much smaller profile.

Gas transmission and storage

Midstream and downstream

-

Cameron T30 Series

Fully welded ball valveLower emissions while improving uptime and profitability.

-

ENTECH DRV-BN

Nozzle check valveLarge-bore design for compressor and pumping stations.

-

ENTECH DRV-Z

Nozzle check valveSmall-bore valve designed for use in piping systems.

-

Grove B4

Trunnion-mounted, side-entry ball valve2- to 4-in sizes, ANSI 150 to 1500.

-

Grove B5

Trunnion-mounted, side-entry ball valveSizes: 6–64+ in; Classes: ANSI 150–1500

-

Grove B7

Side-entry ball valve1 1/2- to 20-in sizes, ANSI 2500.

-

Grove B8

Fully welded ball valve2- to 60-in sizes, ANSI 150 to 2500.

-

Grove BT1

Top-entry ball valve1/2- to 12-in sizes, ANSI 150 to 1500.

-

Grove BT2

Top-entry ball valve1 1/2- to 60-in sizes, ANSI 150 to 2500.

-

Direct-Gas Ledeen Actuators

Efficient modular assemblyAchieve on-off control of ball or plug valves.

-

Gas-Over-Oil Ledeen Actuators

Quarter-turn operationEnhance flexibility with consistent engineering and modular design.

-

Hydraulic Ledeen Actuators

Quarter-turn operationAchieve on-off modulating control of multiple valve types.

-

Pneumatic Ledeen Actuators

Quarter-turn operationReliable performance with compressed air, natural gas, or nitrogen.

-

Ledeen SCCS

Self-contained control systemEnsure reliable valve shutdown when an external powersource is unavailable.

-

Maxtorque

High-performance worm gearsWorm-gear solutions that minimize effort.

-

Tom Wheatley Piston Check Valve

API Spec 6D–compliant valve, especially effective in scenarios with pressure surges and pulsating flowNonslam, reliable operation that stands up to excessive wear.

-

Tom Wheatley Swing Check Valve

API Spec 6D–compliant, fullbore pipeline check valve for demanding environmentsField-proven backflow prevention.

Liquid transmission and storage

Midstream and downstream

-

WKM Pow-R-Seal

Double expanding gate valveEnhanced safety and seal reliability.

-

Cameron T30 Series

Fully welded ball valveLower emissions while improving uptime and profitability.

-

ENTECH DRV-BN

Nozzle check valveLarge-bore design for compressor and pumping stations.

-

ENTECH DRV-Z

Nozzle check valveSmall-bore valve designed for use in piping systems.

-

General Valve Four-Way

Diverter valvePositive sealing without reliance on line or external hydraulic pressure.

-

General Valve Twin Seal

Plug valveThis double block-and-bleed (DBB) plug valve provides a bubble-tight verifiable dual seal without seal abrasion.

-

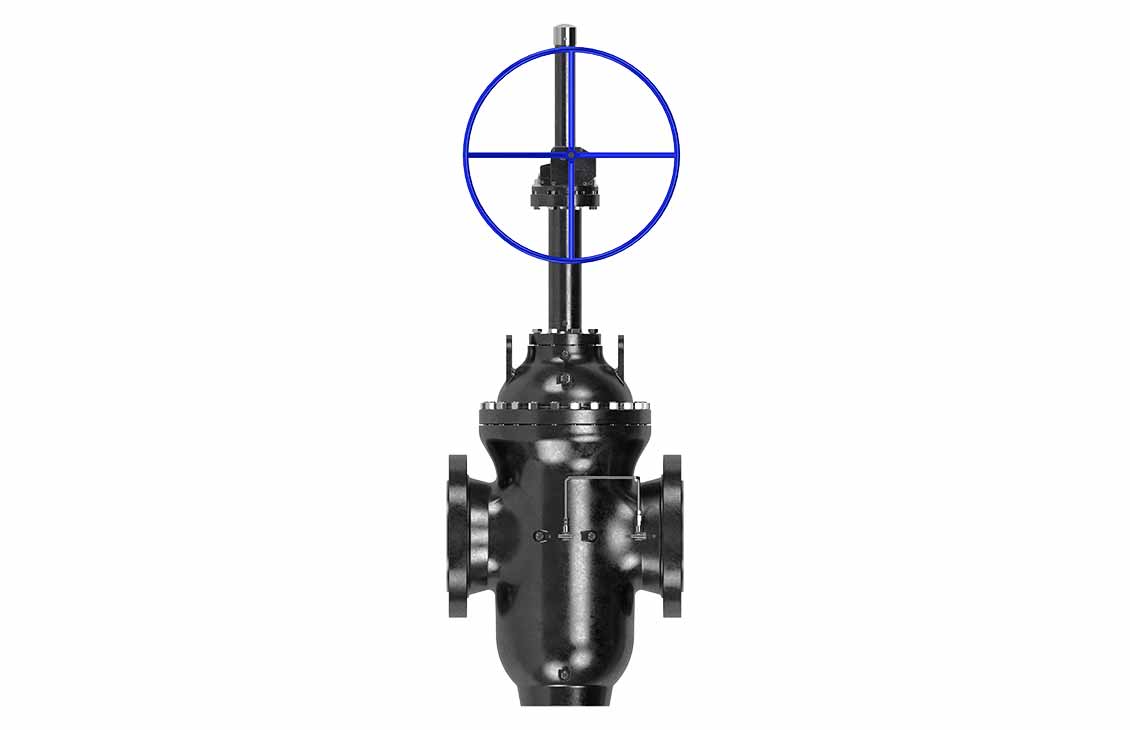

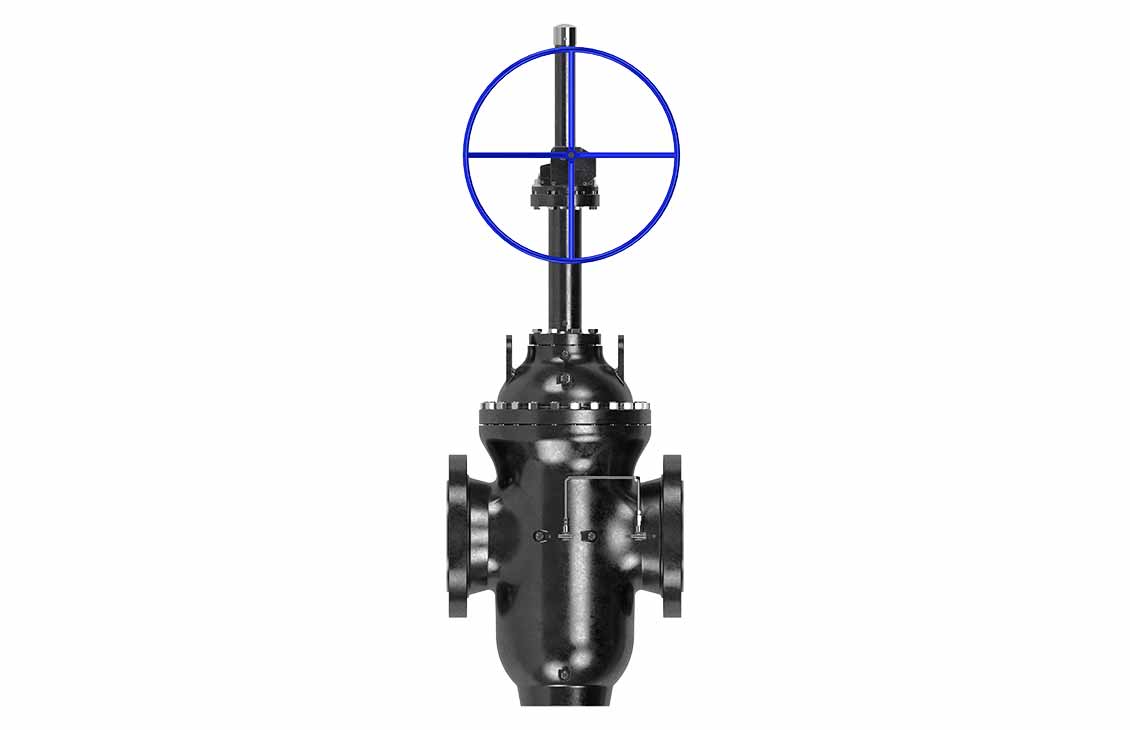

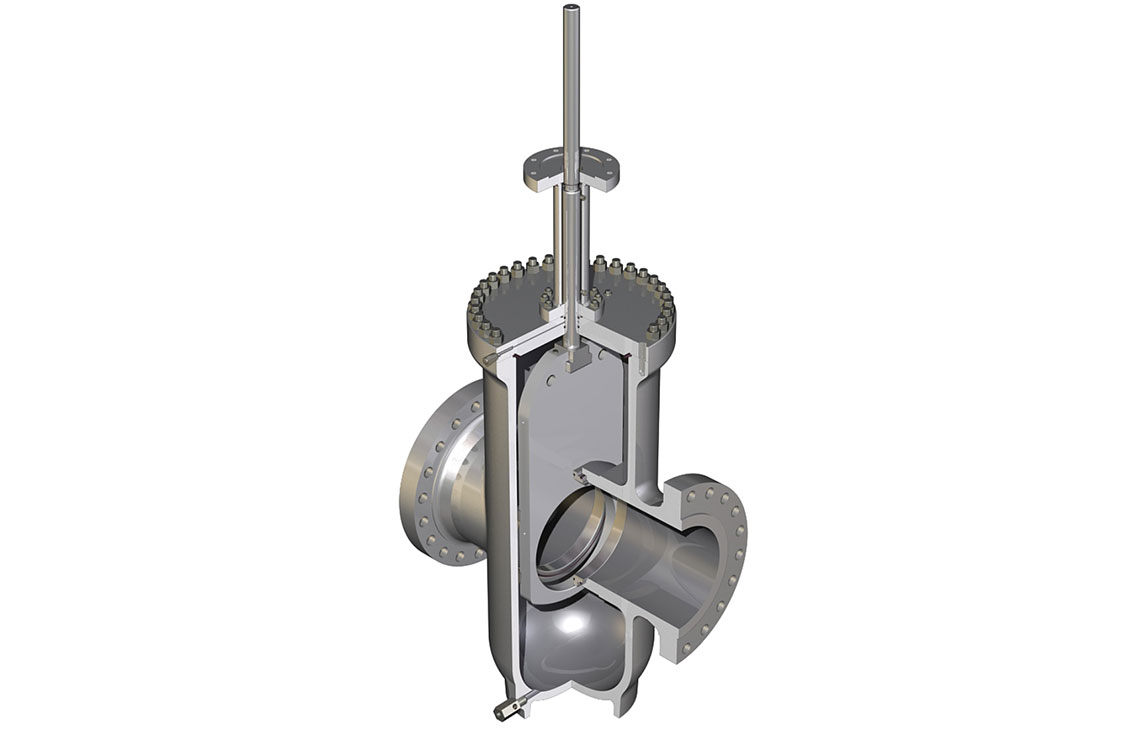

Grove G7

Fabricated gate valveAPI Spec 6D–compliant valve with a through-conduit design that promotes long-term, reliable sealing performance.

-

Grove B4

Trunnion-mounted, side-entry ball valve2- to 4-in sizes, ANSI 150 to 1500.

-

Grove B5

Trunnion-mounted, side-entry ball valveSizes: 6–64+ in; Classes: ANSI 150–1500

-

Grove B7

Side-entry ball valve1 1/2- to 20-in sizes, ANSI 2500.

-

Grove B8

Fully welded ball valve2- to 60-in sizes, ANSI 150 to 2500.

-

Grove BT1

Top-entry ball valve1/2- to 12-in sizes, ANSI 150 to 1500.

-

Grove BT2

Top-entry ball valve1 1/2- to 60-in sizes, ANSI 150 to 2500.

-

Grove G12

ValveThrough-conduit gate valve with a cast body, fully compliant with API Spec 6D.

-

Hydraulic Ledeen Actuators

Quarter-turn operationAchieve on-off modulating control of multiple valve types.

-

Pneumatic Ledeen Actuators

Quarter-turn operationReliable performance with compressed air, natural gas, or nitrogen.

-

Ledeen SCCS

Self-contained control systemEnsure reliable valve shutdown when an external powersource is unavailable.

-

Maxtorque

High-performance worm gearsWorm-gear solutions that minimize effort.

-

Tom Wheatley Piston Check Valve

API Spec 6D–compliant valve, especially effective in scenarios with pressure surges and pulsating flowNonslam, reliable operation that stands up to excessive wear.

-

Tom Wheatley Swing Check Valve

API Spec 6D–compliant, fullbore pipeline check valve for demanding environmentsField-proven backflow prevention.

-

WKM Saf-T-Seal

Slab gate valveSimple yet rugged and reliable through-conduit valve.

Process, refining, and petrochemical

Gas processing, LNG, and NGL