Tech Paper Restoration of High-Temperature Well Integrity

Real-time CT services and expandable steel patch repair tubing leak in high-rate gas well.

For oil and gas well casing leak repair, perforation shutoff, and tubing repair and geothermal well integrity restoration

Saltel expandable steel patches are a permanent solution, capable of molding to irregular geometries to create a high-pressure inner lining that seals off and protects damaged casing or tubing from further loss of integrity. Overlapping patches can be used across long breaches. The large ID enables nearly unrestricted access to the wellbore below, so drilling, completion, or well intervention operations can continue and most bottomhole assemblies can pass through as required.

Made of high-quality stainless steel, the patch uses a profiled sealing system that conforms to varying IDs and is applied and cured in a controlled environment during manufacturing, employing different materials based on the application requirements—unlike the field-applied epoxy resin used by some providers. Our engineered system provides a resilient and reliable seal that is able to withstand significant differential pressures and thermal cycling, which can compromise the integrity of alternative sealing technologies over time. In addition to the profiled external seals, the patches can be secured with anchoring strips to mitigate slippage risks due to axial loads and withstand the lateral forces and wear encountered if drilling ahead.

A casing patch using our field-proven Saltel Xpandable™ expandable steel technology requires less time to accurately position and install across unwanted perforations compared with conducting a cement squeeze. It does not significantly restrict wellbore access and only requires water to activate the inflatable packer used for controlled expansion of the patch against the casing—even a corroded or ovalized casing. Perforation shutoff can be completed in as little as two days. In contrast, traditional methods for sealing unwanted perforations by squeezing cement into them are lengthy, multistep operations that can last for days. Our expandable casing patches are also a more resilient long-term solution for perforation shutoff. Find out more.

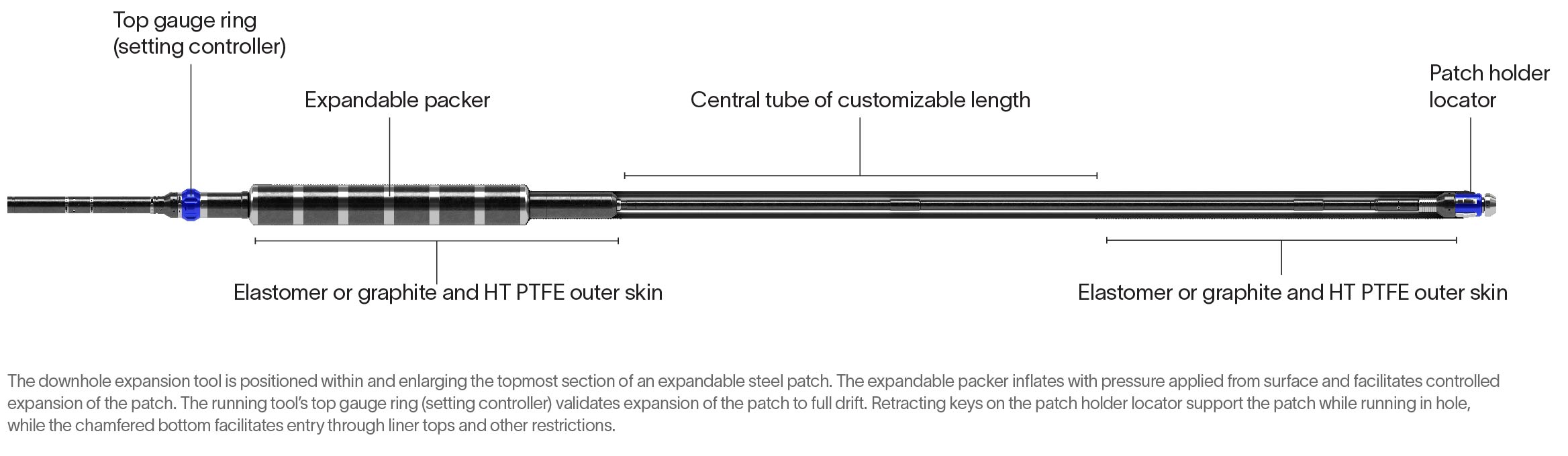

The downhole expansion tool is positioned inside the patch and its packer section is inflated enough to grip the inside of the patch. The assembly is run in hole, and once it is at depth, the packer is further inflated using pressure from surface. The top of the patch expands and is pushed against the casing or tubing being repaired to activate the outer seals and anchor the patch in place. The packer is subsequently deflated, run in another 3 ft [1 m], and reinflated. The process is repeated until the full length of the steel patch has been expanded. By expanding the patch from the top down, the risk of a stuck setting tool is minimized.