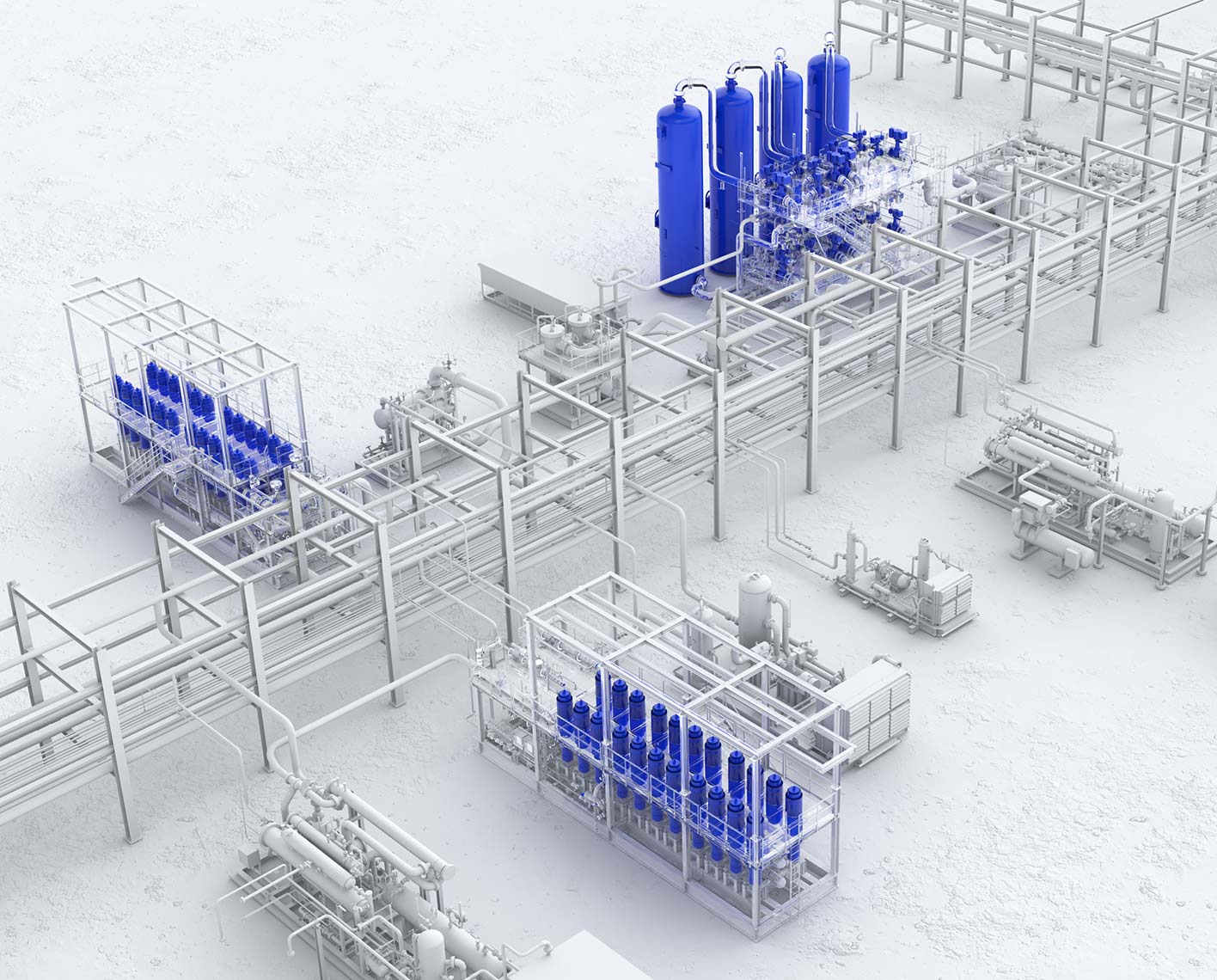

Gas treatment

Facilitating the recovery, treatment, and monetization of natural gas

Reduce CO2, H2S acid gases, and VOCs

There are inherent impurities in gas that not only accelerate the corrosion of pipelines and transmission control equipment—such as CO2, often deadly H2S acid gases, and volatile organic compounds (VOCs)—but also lower the heating value of the gas and contribute to fugitive emissions. These impurities must be removed prior to transmitting gas to a processing facility.

Experience optimal gas treatment

Our differentiating technology portfolio and expertise in process design and engineering provide the optimal gas treatment based on the parameters of your specific operation, including acid treatment, emissions control, glycol dehydration, natural gas liquid recovery, phase separation, and more. When you're planning your next front-end engineering and design (FEED) study, we can help you make the most of your natural gas recovery, treatment, and monetization.

Effectively remove hydrogen sulfide (H2S) from saleable natural gas streams using proven gas sweetening processes.

Emission Control Systems

Reduce emissions in natural gas facilities to comply with local environmental regulations.

Reduce emission of volatile organic compounds

Our systems enable natural gas facilities to comply with local emissions regulations.

Extract water from a CO2 stream to prevent hydrate formation and corrosion in pipelines.

Natural Gas Liquid (NGL) Recovery

Increase your revenue while preparing gas to meet pipeline specifications.

Recover valuable hydrocarbon liquids while preparing gas to meet specifications

Our dew point control systems and NGL recovery technologies maximize hydrocarbon recovery from gas streams, increasing profitability.

Phase Separation

Remove solids and liquids in gas entering a treatment facility before sending to additional processing and purification.

Flexible and highly efficient separation of liquids and solids from gas streams

Gas entering a treatment facility can contain solids and liquids, either as particulates or as a distinct phase, that must be removed before additional processing and purification.

-

High-Efficiency Phase Separation Internals

Enhance separation of oil, gas, sand, and waterImprove separation of oil, gas, sand, and water while reducing costs and risk.

-

PORTA-TEST WHIRLYSCRUB I

Liquid removal from gases with low liquid loadingRemove liquids from gas containing low amounts of liquid, with a removal efficiency of 99.99% down to 10 um.

-

PORTA-TEST WHIRLYSCRUB V

Solids and liquid removal from gases with moderate amounts of liquidsRemove solids and liquid from gas containing moderate amounts of liquid, with a removal efficiency of 99.9% down to 10 um.

Maximize recovery of monoethylene glycol (MEG) in your hydrate management process.

Optimize your treatment solution

Let's collaborate early to understand project drivers, assess options, and design the solution that best fits your project needs to deploy the right technology to maximize performance.