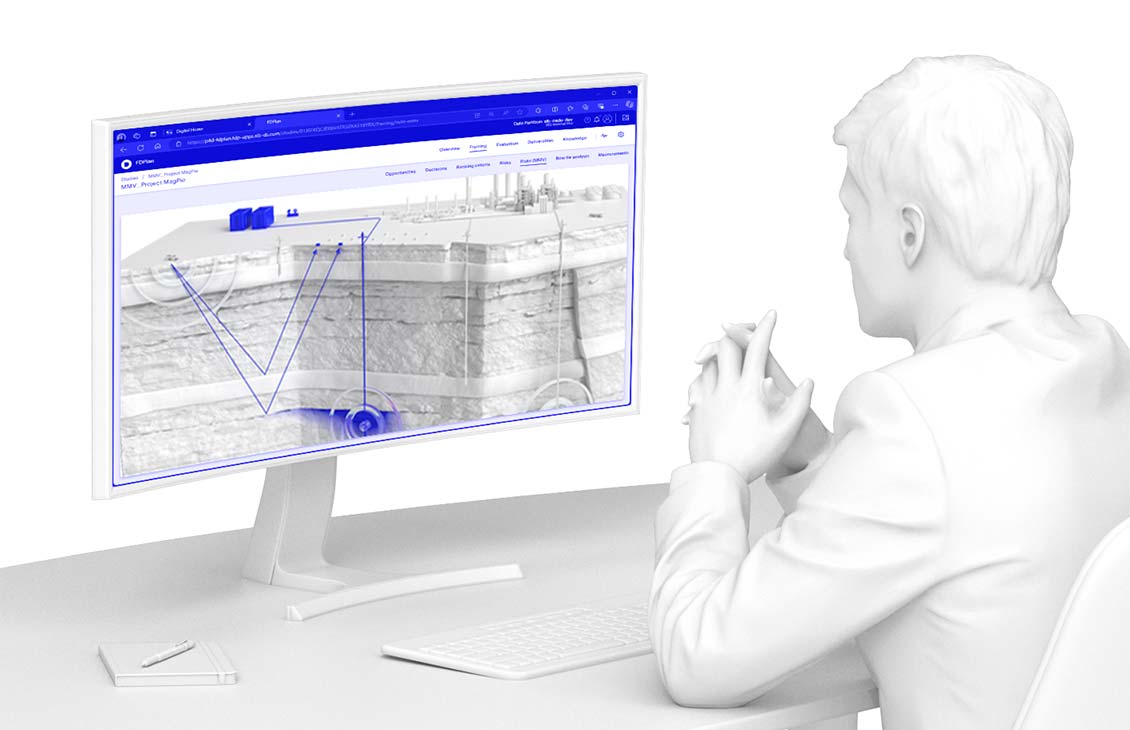

Carbon storage injection operations, measurements, monitoring, and verification

Cost-effective CO₂ injection planning and management

Simplifying the planning, implementation, and operations of carbon storage

After you've selected a potential site for carbon storage, the next challenge involves creating a measurements, monitoring, and verification (MMV) plan. This includes detailed technology specifications, interfaces, data workflows, associated costs, and handling ongoing injection operations. The analysis and results of these steps will determine whether your site meets regulatory approvals and is economically viable.

Our Sequestri™ carbon storage solutions provide a comprehensive portfolio of solutions to simplify the complexity of developing and managing carbon storage sites, including MMV planning and execution.

MMV planning

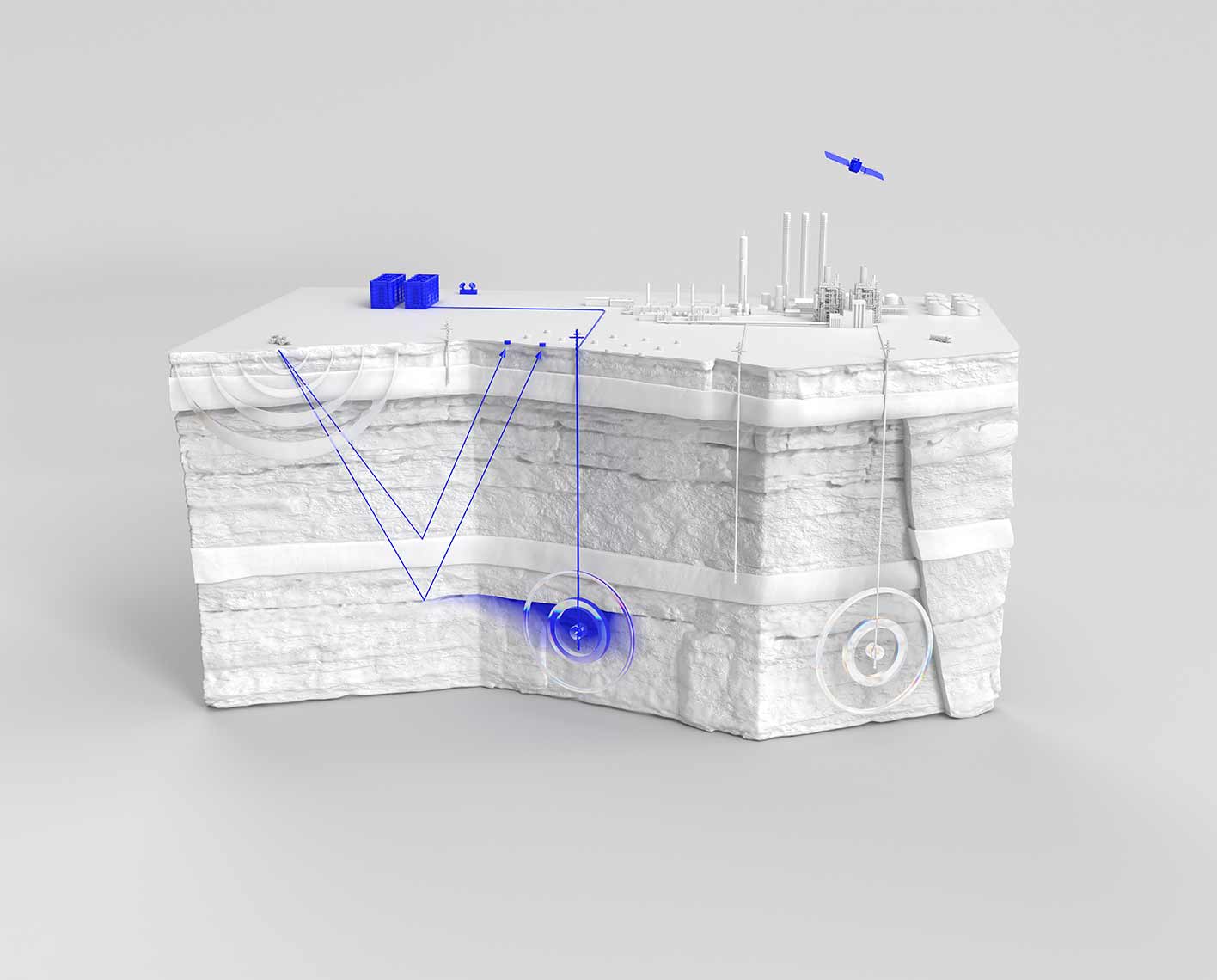

Ensuring the secure containment of CO2 in a storage site is crucial for minimizing environmental risks. As such, most regulators have created frameworks with which carbon storage developers must comply to reduce risks. One of the key requirements for regulatory approval is the development of a thorough MMV plan.

We have developed compliant, cost-effective, and site-specific MMV plans for permitting, front-end engineering design (FEED), and final investment decision (FID) across multiple countries around the world. Let us help you.

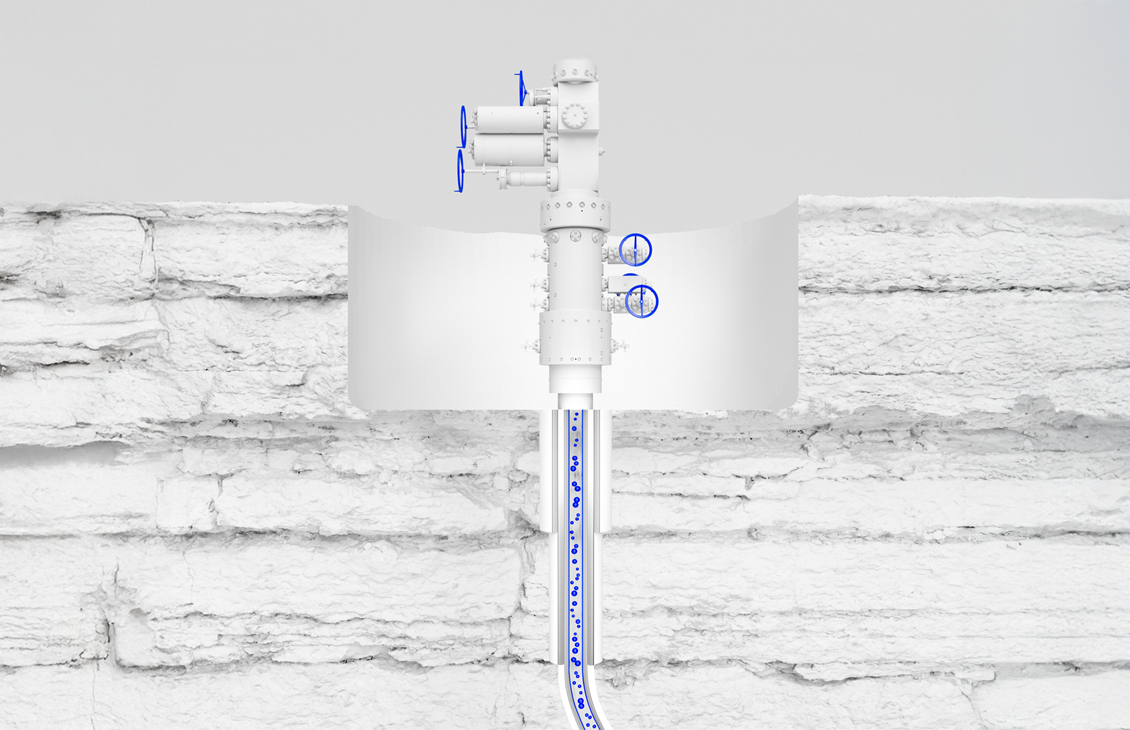

MMV technologies

To comprehensively understand capacity, containment, and injectivity, you must take measures to establish a baseline for appraising the carbon storage site and to develop and execute a carbon storage monitoring program. This ensures a well-informed and effective approach to carbon sequestration.

From permanent monitoring to verification measurements, we've got you covered.

MMV front-end-engineering design (FEED)

MMV FEED encompasses the detailed design and planning required to track, measure, and monitor CO2 throughout a project's lifecycle, ensuring both safe storage and regulatory compliance. With extensive experience in FEED for carbon capture and storage (CCS) as well as oil and gas projects, SLB provides expert guidance to streamline your FEED process.

We assist in defining the technical designs and installation plans for your chosen monitoring systems, estimating costs, ensuring compliance with regulatory standards, and devising effective mitigation strategies. Let our experts help you build a solid foundation for your project’s success.

MMV baseline and infrastructure deployment

Before and during the construction phase of the storage site, we offer a wide range of services to ensure regulatory compliance and minimize risks. This includes project management and oversight of MMV technologies baseline measurements, field installation and deployment of monitoring technologies, the supporting IT infrastructure, system integration, MMV management system testing, and preoperational validation. Once you’ve passed FID, we can help you get up and running faster.

CO₂ injection operations

In conjunction with our measurement technologies, we can provide injection operations management support and services, including surveillance of injection operations, regulatory reporting, storage performance management services, plume, flow and reservoir model updates and history matching, and IT systems and data management services.

Be storage confident

Other carbon storage solutions

Carbon storage site evaluation

In-depth analysis to evaluate your carbon storage project

Carbon storage injection operations, measurements, monitoring, and verification

Cost-effective CO₂ injection planning and management

Carbon storage well design and construction

Designing and constructing CCS-specific wells to withstand the test of time

Carbon storage regulatory permitting

Regulatory permitting for Class VI or CO₂ injection wells