Smart Production Operations

Solve your most challenging problems quickly using our network of data and domain experts

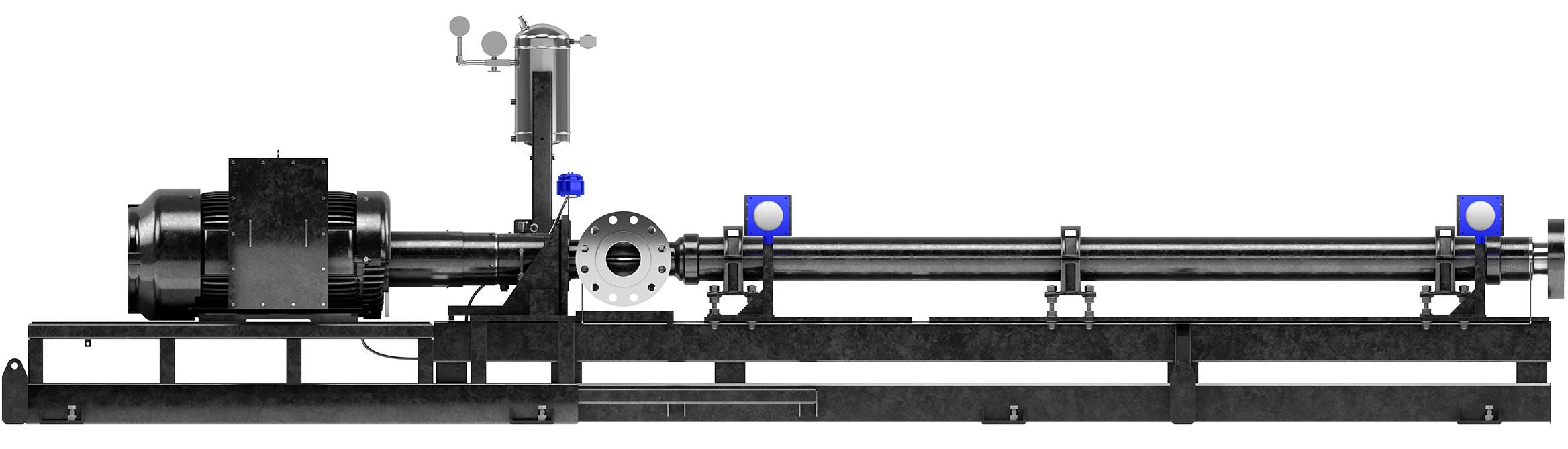

Remote and unmanned production environments often struggle with equipment reliability, fluctuating volume demands, and operational efficiency. The third-generation Reda HPS™ horizontal multistage surface pumping system is engineered to meet these challenges, and its reliability, scalability, and flexibility have been proven over thousands of deployments worldwide. Designed with a modular footprint and proven single-stage pump technology, it delivers high efficiency across variable loads and reduces unplanned downtime. Whether for water or CO2 injection, fluid transfer, or pressure boosting, this surface pumping system ensures continuous, energy-efficient operation while optimizing life cycle costs.

Provides a robust and efficient injection solution in harsh conditions in diverse EOR scenarios

Facilitates reinjection of high-volume water streams with consistent pressure and efficiency

Enables continuous condensate removal without the need for gas-driven lift systems

Ensures agility in pad-based developments where modularity and rapid mobilization are essential

Optimizes flow rates to effectively overcome pressure challenges and increase production capacity

Maintains production flow rates under variable pressures for onshore or terminal locations

Supports steady-state fluid handling across long distances with minimal operator intervention

Eliminates the need for multiple lower-pressure units, cutting costs and minimizing downtime

Injects water back into the reservoir in geothermal power plants

with proven pump stages and rugged motor designs validated across thousands of deployments. A Texas midstream operator replaced a high-maintenance surface pump with a Reda HPS pumping system, reducing pump maintenance downtime by 95%, more than doubling throughput.

via extended run life and fewer moving parts compared with reciprocating or diesel-driven systems.

thanks to modular, field-configurable pump stages. In Gabon, a Reda HPS pumping system configuration quadrupled the operator’s waterflood capability without the need for infrastructure changes.

Input your pumping parameters and receive an initial system design to help determine your best option.