Completions that maximize recovery and extend well life

SLB completions technology optimizes reservoir contact and sustains production across the life of the well—integrating hardware, stimulation, artificial lift, and digital monitoring to increase recovery, reduce operating costs, and lower emissions.

Every completion decision shapes the economics of your well

Reservoirs are growing more complex. Tighter formations, deeper targets, longer laterals, and multizone developments demand completion designs that perform under extreme conditions—and deliver returns under intense cost pressure. At the same time, operators face stricter emissions mandates and shorter timelines to first production, leaving little margin for underperforming completions or unplanned interventions. The challenge extends beyond the initial completion.

Production decline, equipment failures, and inefficient lift systems erode recovery over the well's lifetime. Without integrated monitoring and control, operators lose visibility into downhole conditions—reacting to problems instead of preventing them.

Dive Deeper

Completion Fluids and Wellbore Cleaning Tools

Accelerate and maximize production with minimal HSE impact

Optimize reservoir output with stimulation solutions

Unlock greater recovery, reduce emissions, and cut costs with fully integrated fracturing, acidizing, and water management workflows.

Artificial Lift

Integrated lifting solutions for enhanced well production

Surface and downhole logging

Advanced tools, services, and expertise to log any well

Measurable outcomes from completions to production

Well uptime improved from 85% to 96%

A Permian Basin operator achieved this improvement using SLB intelligent lift services, which apply AI-driven analytics and 24/7 remote monitoring to optimize artificial lift performance and prevent unplanned downtime.

USD 500,000 saved and 10 days recovered on a single pad

SLB's dual-fracturing stimulation service enabled simultaneous fracturing operations for Sundance Energy, increasing proppant placed by 35% per day compared with conventional zipper fracs while significantly reducing equipment rental costs.

Up to 80% fewer lift system failures versus rod lift

SLB ESPCP systems eliminate sucker rods entirely, removing the primary cause of tubing holes and parted rods that trigger workovers and production deferrals in mature wells.

Up to 25% reduction in fracturing carbon emissions

Hiway Flex™ customizable flow-channel fracturing technology uses a tailored mix of premium proppant and sand to create highly conductive fractures while reducing the material volume, logistics footprint, and carbon intensity of each treatment.

Thousands of stimulation scenarios evaluated in hours

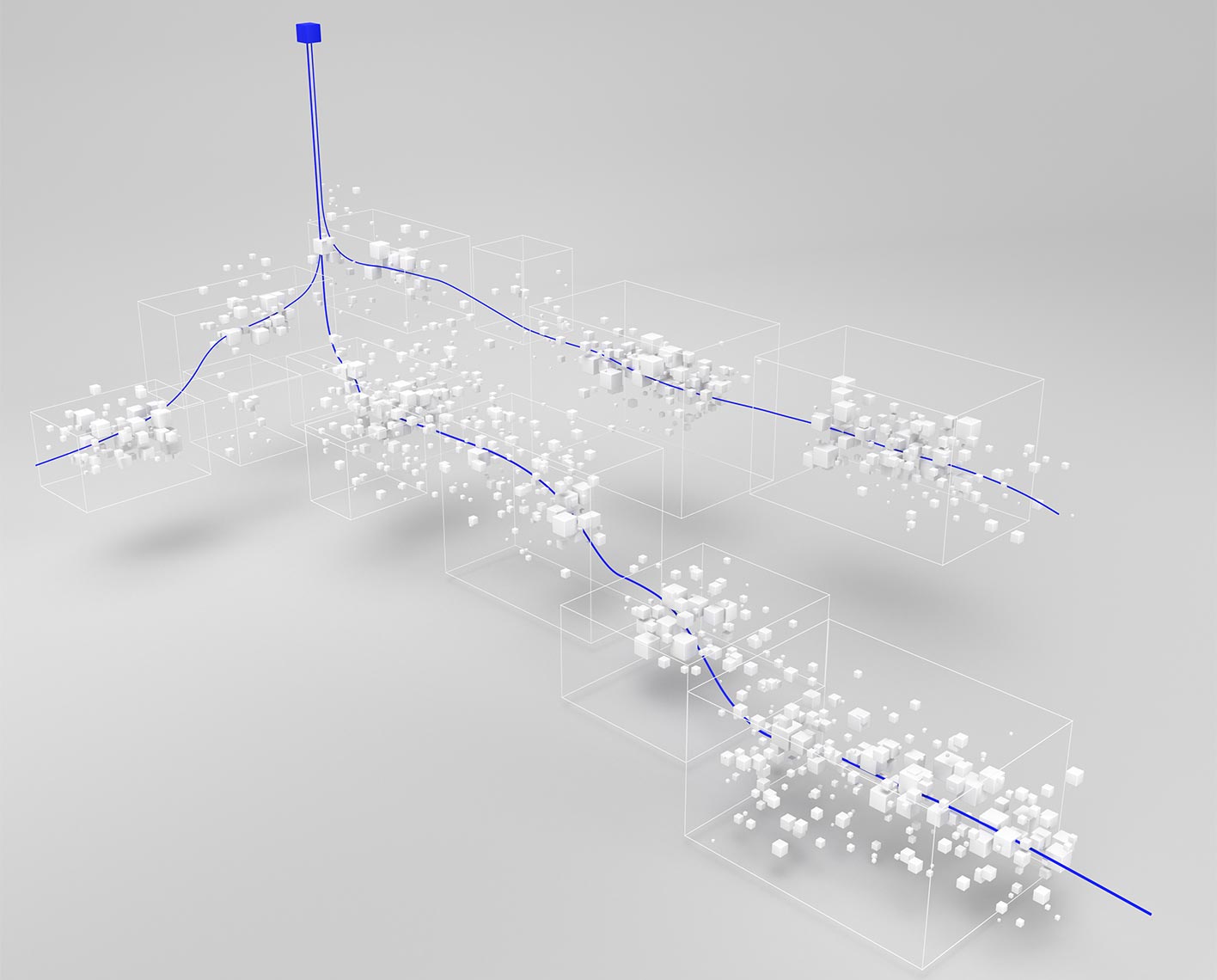

Kinetix™ reservoir-centric stimulation-to-production software integrates geology, geomechanics, and completion engineering on the Petrel™ E&P software platform, enabling automated parallel processing that compresses weeks of design work into hours.

Technology that connects completions performance to production outcomes

- Electris™ electric completions — SLB's electric completions platform empowers operators to predict, adapt, and act with confidence throughout the life of the well. By combining downhole sensors, inflow control, and real-time data transmission, Electris completions enable autonomous reservoir management without intervention.

- Intelligent well stimulation — SLB's intelligent stimulation workflows reduce subsurface data processing from weeks to three days, ensuring that fracturing and acidizing decisions are based on consistent, accurate reservoir insights. These workflows optimize lateral landing, cluster efficiency, and well spacing for maximum recovery.

- Full-spectrum artificial lift — SLB provides electric submersible pumps with production rates from 200 to 95,000 bbl/d, gas lift systems for high-gas-ratio and deviated wells, progressing cavity pumps for heavy oil, and rod lift systems for mature wells—each backed by digital optimization services.

- Automated stimulation delivery — SLB's StimCommander™ automated stimulation platform and frac and flowback equipment portfolio—including DeepSTIM™ deepwater stimulation vessels and FlexSTIM™ modular offshore systems—deliver automated, high-efficiency fracturing and acidizing operations on land and offshore.

- Completion fluids and wellbore preparation — SLB's M-I SWACO completion fluids include clear brines, reservoir drill-in fluids, packer fluids, and filtercake breakers engineered to minimize formation damage. The SMART 3D displacement strategy integrates chemical, mechanical, and hydraulic technologies to deliver a clean wellbore in a single displacement operation.

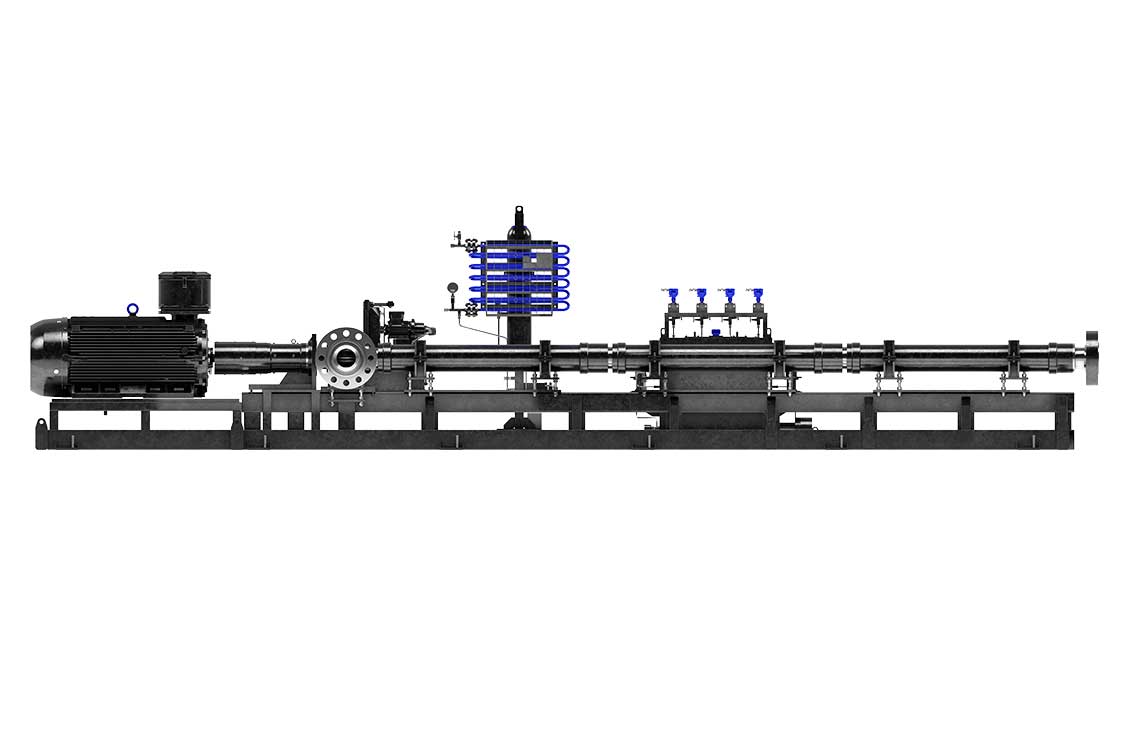

- Reda HPS™ horizontal surface pumping systems — SLB's Reda HPS pumps serve oil and gas, mine dewatering, carbon sequestration, and geothermal applications with a modular, maintenance-free design that handles discharge pressures up to 6,650 psi. A high-gas-volume-fraction model handles up to 90% GVF for zero-flaring well tests and production boosting.

Featured products

FAQ

How does SLB help reduce completion costs in unconventional wells?

SLB reduces unconventional completion costs through automation, optimized treatment design, and integrated workflows. The dual-fracturing stimulation service enables simultaneous operations on multiwell pads, reducing equipment time on location—one operator saved USD 500,000 and 10 days on a single pad. Kinetix software evaluates thousands of completion scenarios in hours to identify the most cost-effective design before pumping begins. SLB also offers dissolvable frac plugs and automated blender systems that reduce time between stages.

What artificial lift system should I choose for my well conditions?

SLB offers artificial lift systems for every flow rate and operating environment. Electric submersible pumps suit high-rate production from 200 to 95,000 bbl/d. Gas lift handles high-gas-ratio, deviated, and sandy wells. Rod lift serves lower-rate conventional wells. For mature wells transitioning from ESP to lower rates, SLB ESPCP systems eliminate rod-related failures that account for up to 80% of rod lift downtime. SLB's intelligent lift service uses AI analytics to help operators select and optimize the right system for changing well conditions.

How does SLB help reduce emissions during completions and stimulation?

SLB addresses completions emissions through multiple technologies. Hiway Flex flow-channel fracturing technology reduces fracturing carbon intensity by up to 25% by using less proppant with tailored material blends. ESPCP systems lower power consumption and related CO2 emissions compared with conventional rod lift. SLB's Reda HPS pumps support zero-flaring well tests by handling up to 90% gas volume fraction at surface. Across operations, SLB's automated stimulation equipment reduces fuel use and truck movements on location.

What is electric completions technology and how does it improve reservoir management?

Electris electric completions from SLB represent a step change in how operators manage reservoirs over the life of the well. The system combines downhole sensors, electric inflow control, and real-time telemetry to give operators continuous visibility into zonal production. SLB electric completions enable operators to predict, adapt, and act on changing reservoir conditions without costly well interventions—optimizing drainage, delaying water breakthrough, and extending productive well life.

How does SLB optimize hydraulic fracturing design for different reservoir types?

SLB optimizes fracturing with intelligent well stimulation workflows that integrate geology, petrophysics, and geomechanics into every treatment design. The Kinetix software platform enables automated simulation of thousands of well-spacing and treatment-design scenarios, compressing weeks of engineering into hours. For carbonate formations, SLB's acidizing services use advanced modeling and self-diverting acid systems to maximize reservoir contact. In deepwater environments, SLB deploys DeepSTIM and FlexSTIM vessel-based stimulation to deliver fracturing and acid treatments in extreme conditions.