Lithium brine resource modeling

Explore, develop, and optimize production of lithium-rich brine resources

Efficiently explore, evaluate, and develop lithium-rich brine resources using the SLB advanced subsurface modeling technologies. To meet the growing global demand for lithium—projected to reach nearly 4.0 metric megatons of lithium carbonate equivalent (LCE) by 2040—operators must identify new reserves and optimize production from existing sources.

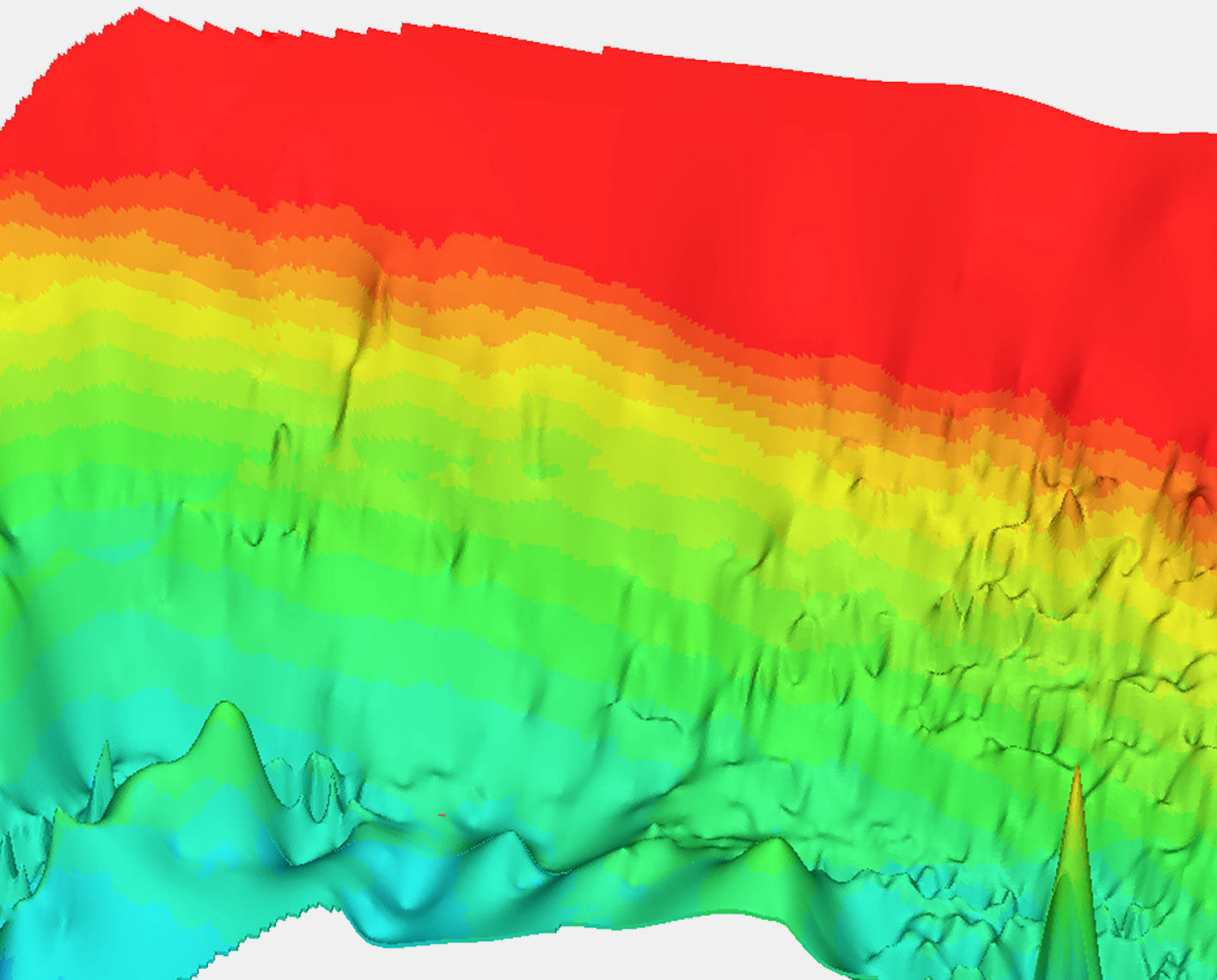

3D basin modeling integrates geological, geophysical, and geochemical data to reconstruct the basin history. This offers valuable insights into brine reservoir porosity characteristics within a sedimentary basin. Calculated temperature and pressure will enable to simulate the release of lithium from its host rocks.

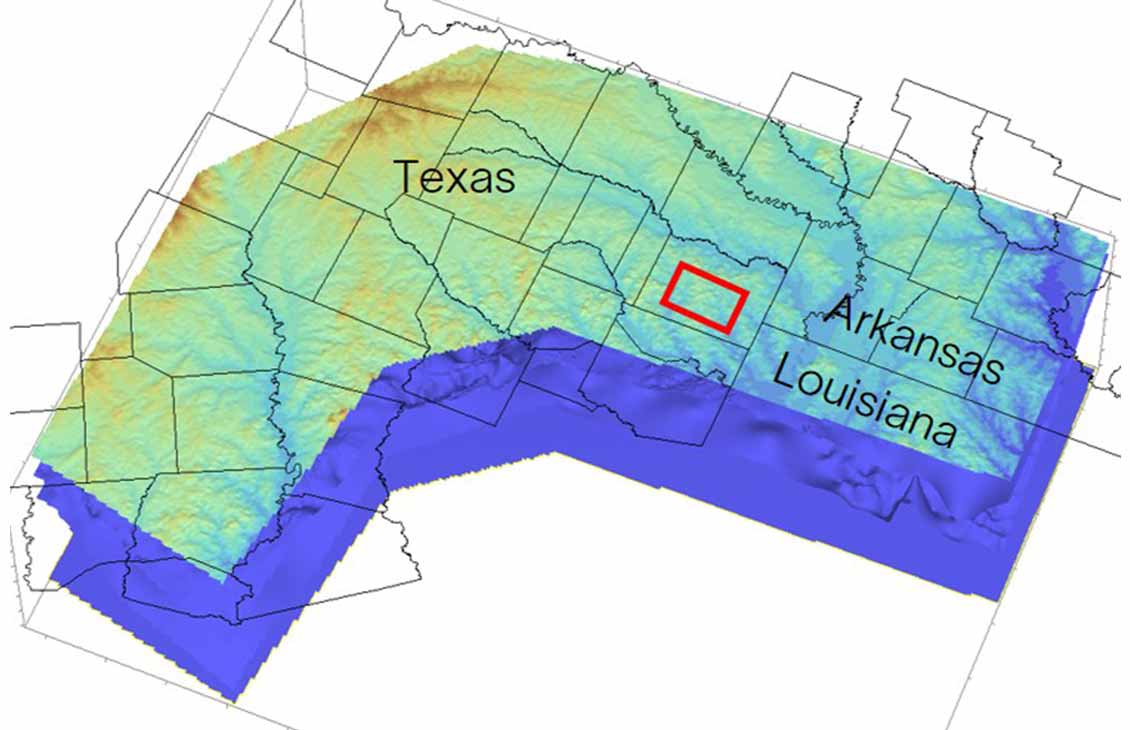

Explore SLB’s Smackover Formation services

SLB provides targeted solutions for the Smackover Formation, a key lithium brine play in the US.

-

Smackover Play

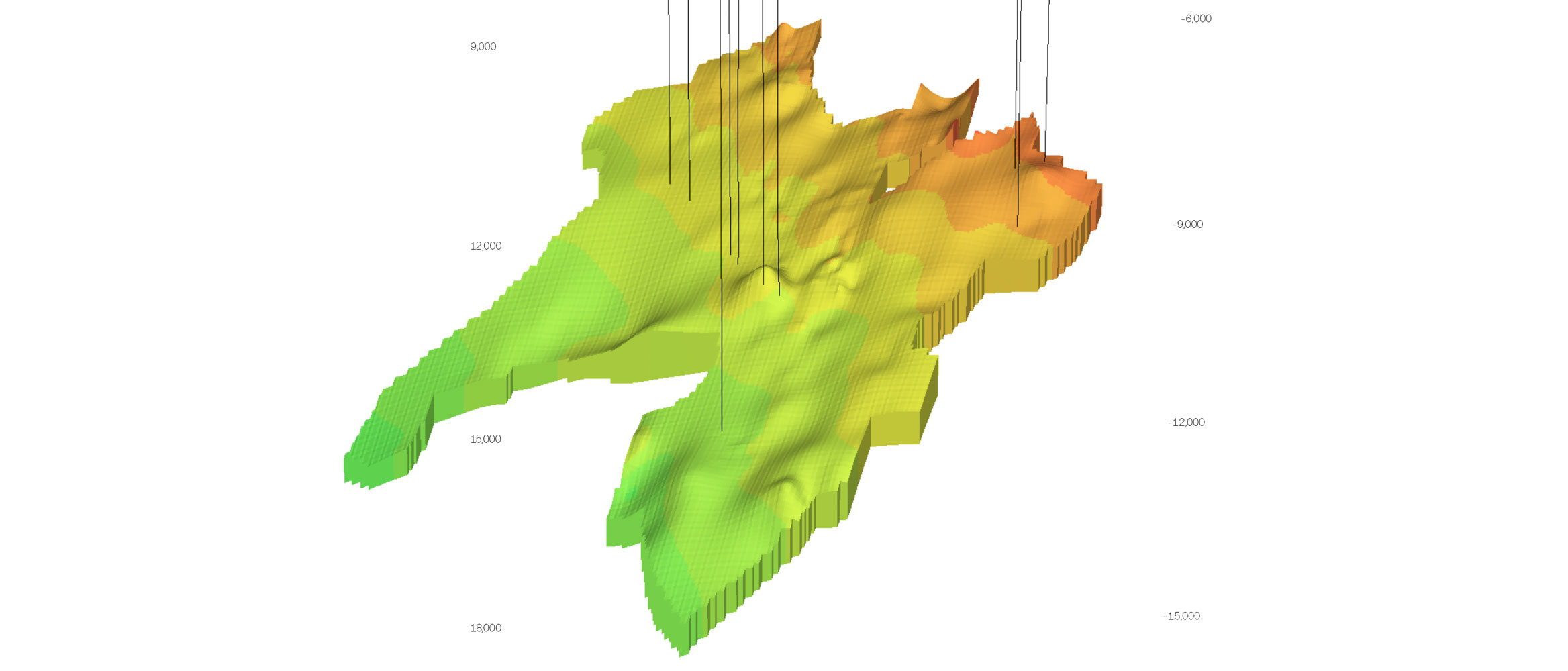

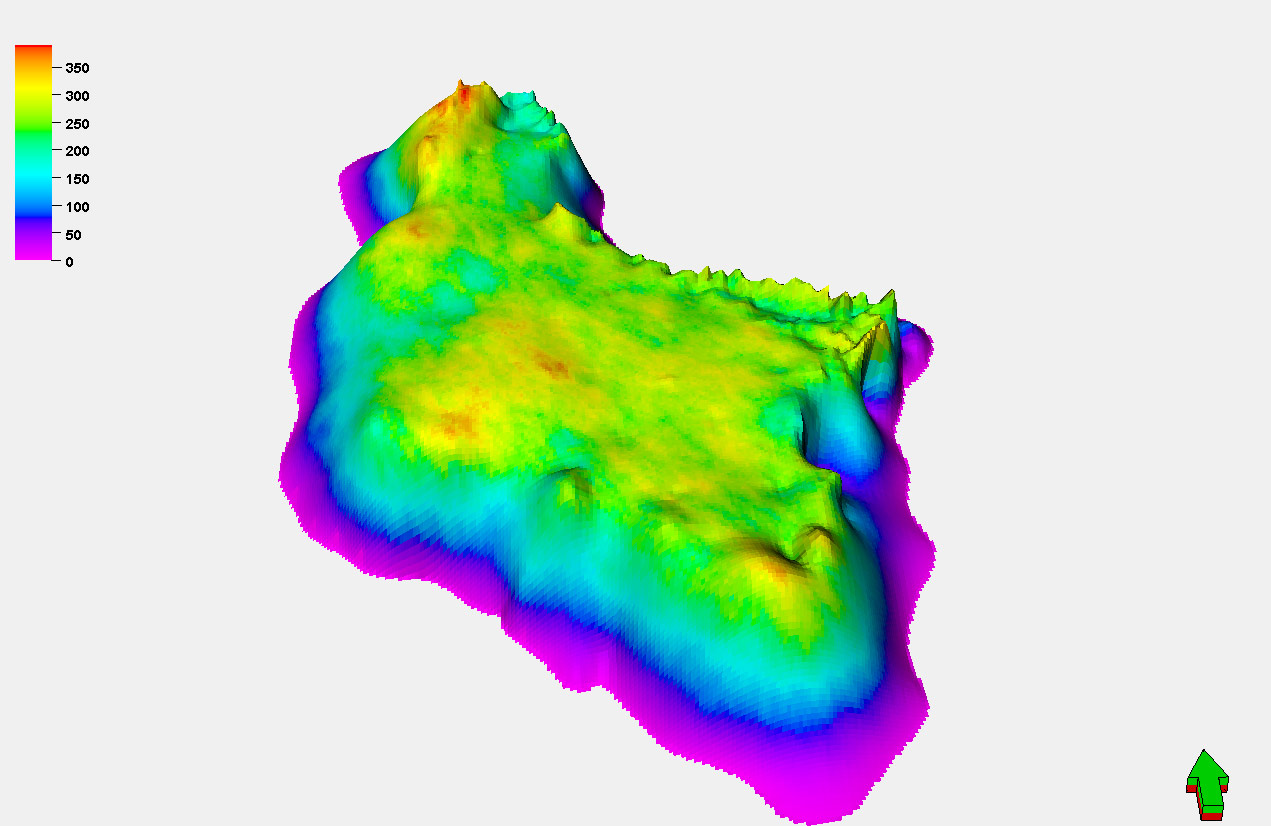

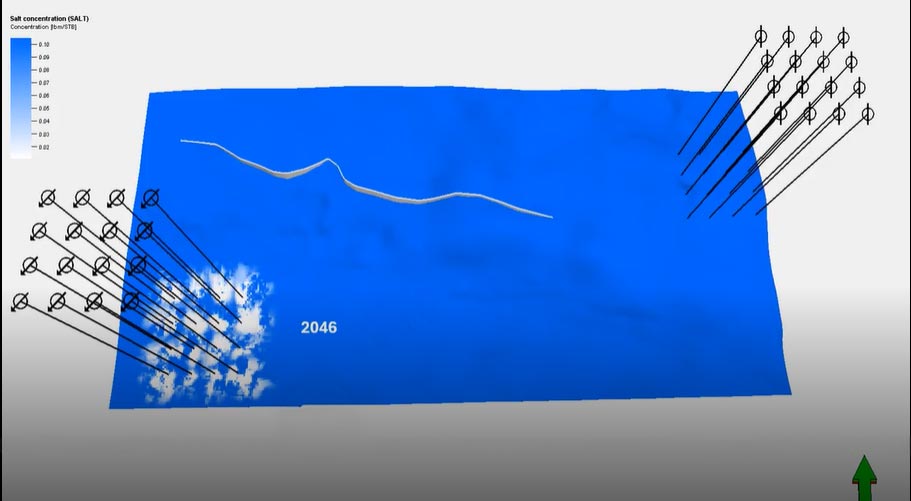

Lithium brine basin resource reportSmackover Play 3D basin model of lithium resources in place for exploration, extraction, and production.

-

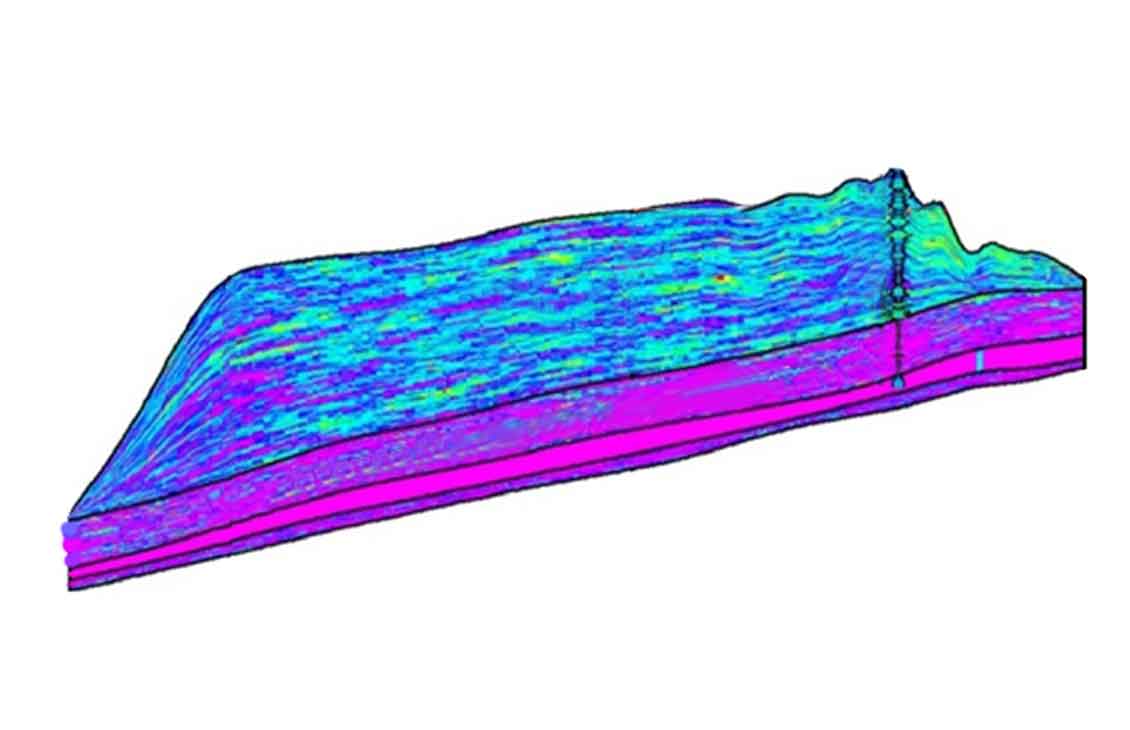

Smackover 3D five-layer model

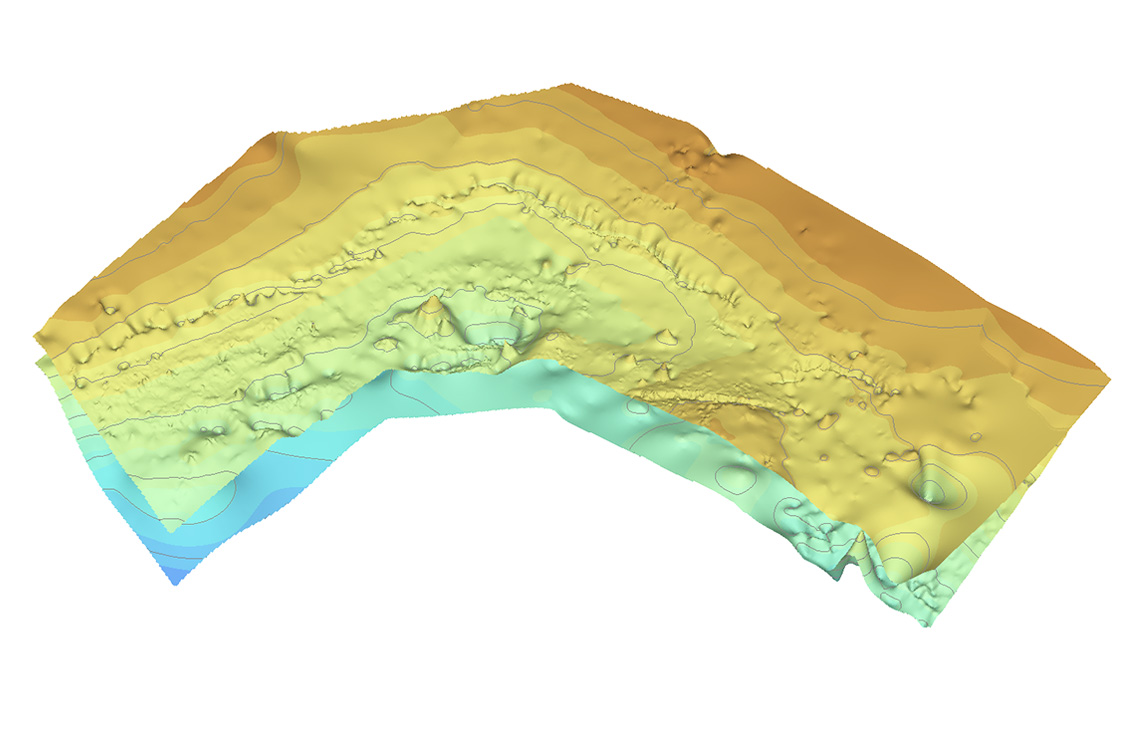

Providing detailed, five-layered geological insights to identify lithium-rich zones faster and with higher certainty in the Smackover FormationSLB delivers detailed geological models for your area of interest—quickly and cost-effectively.

3D static modeling incorporates geological, geophysical, and petrophysical data to model the spatial distribution of rock properties such as porosity, permeability, lithology, and fluid saturation.

Browse the case studies

-

Advanced Modeling Improves Lithium Brine Resource Estimates

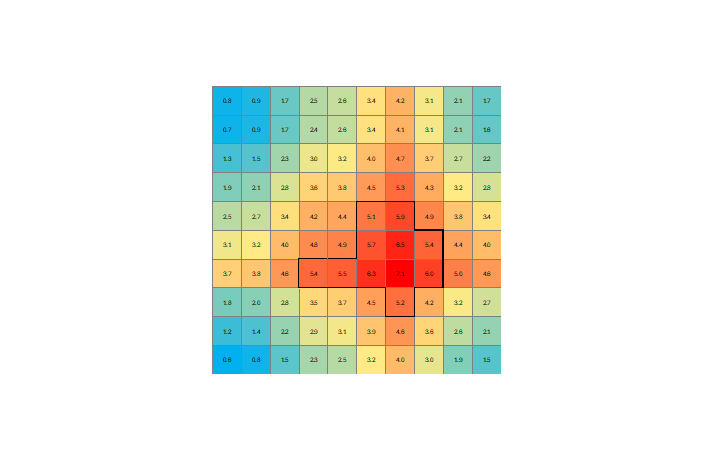

Robust 3D modeling and quantification of lithium brine resources in place within the mapped area of interestExpertise in lithium extraction technologies enabled the customer to refine their lithium resource estimates.

-

Driving Exploration Success via More Accurate Estimation of Lithium Resources

SLB software and modeling algorithms led to >30% increase in lithium resource estimates with high confidence.

-

Derisking Exploration and Accelerating Development of a Lithium Brine Project

Proprietary SLB software and workflows helped estimate the resource in place and identify optimal drilling locations.

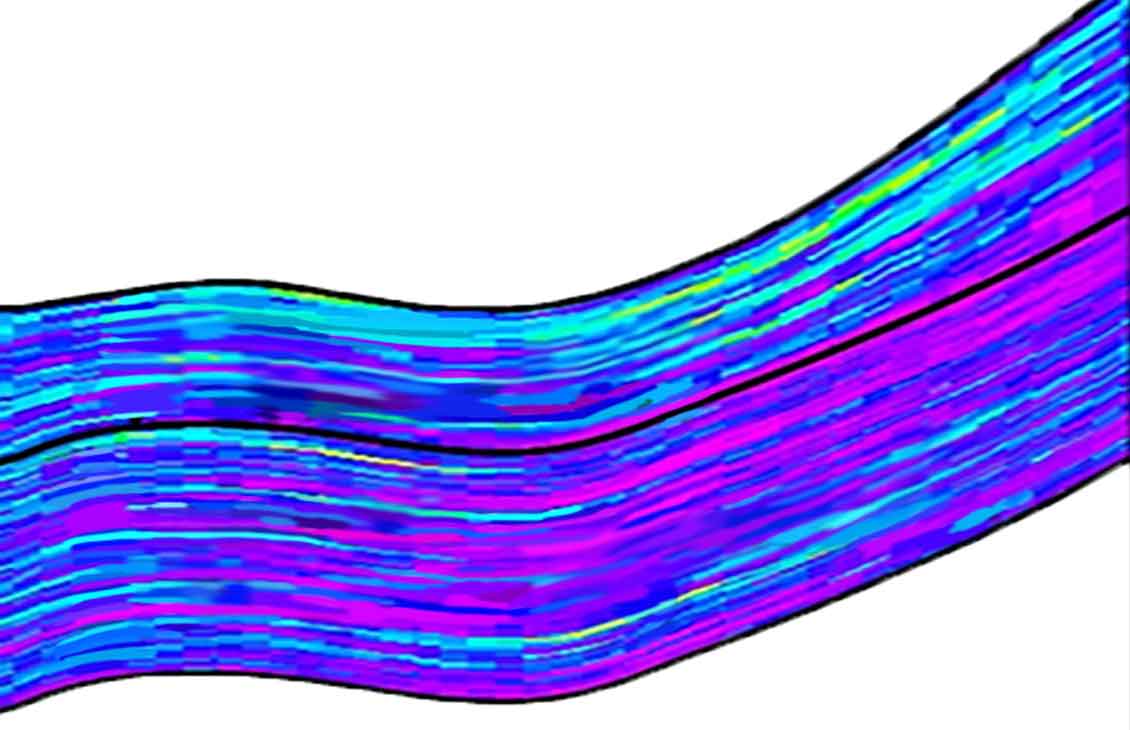

3D aqueous flow modeling provides a day-1 estimate of brine and lithium production. It is used to provide additional assurance for pre-FEED or basic engineering and to gain a more detailed understanding of well count and cost.

3D dynamic modeling predicts, optimizes, and manages lithium reserves. It evaluates various field development concepts, operating strategies, and drilling schedules to find the best combination to achieve target objective.

Maximize lithium resource potential

Maximize resource potential

Accurately characterize reservoirs and simulate production to guide development decisions.

Accelerate project timelines

Reduce uncertainty and improve planning with high-resolution subsurface insights.

Enhance sustainability

Use aqueous flow and dynamic models to design more efficient extraction and reinjection strategies.

Leverage global expertise

Tap into SLB’s 100 years of subsurface experience and proven workflows.

Applications

- Augment in-house expertise with SLB’s subsurface modeling specialists

- Build basin, static, aqueous flow, and dynamic models tailored to lithium workflows

- Evaluate economic potential and optimize lithium-in-place estimates

- Mitigate exploration risks and improve confidence in resource reporting

- Optimize capex investments through improved field development planning

- Develop your resource for long-term sustainability

By your side every step of the project

Through a combination of subsurface expertise and our sustainable lithium production project engineering, implementation, and operational experience, we combine deep technical and scientific knowledge with the experience and learnings from commercial-scale technology integration and deployment.

We deliver insights and better-informed actions from every perspective. From evaluating the individual lithium-brine resource to extraction and reinjection, the SLB 3D subsurface models help customers gain the knowledge to confidently develop the best technological and economic solution.