Production Express

Rapid production response solutions

Never lose a single barrel of production

Production Express™ rapid production response solutions help you overcome temporary production challenges either in the field or at the production facility. No matter your challenge, Production Express solutions are fit to your objectives—whether you need an "express" early production facility (EPF), fluid preconditioning, surface pressure boosting, gas monetization, debottlenecking, or facility and pipeline commissioning and maintenance.

This portfolio of solutions leverages our extensive domain expertise and surface well test equipment to quickly bring your production forward and avoid shutdowns. By using existing yet customizable and compact equipment, Production Express solutions reduce capex while ensuring cash flow and continuous well deliverability—even in remote locations.

Express EPF

Accelerate production while your permanent facility is being built.

Our "express" EPF solution enables faster startup than conventional EPFs—typically within 10 to 12 months. This mobile, modular system delivers early cash flow and valuable reservoir insights while meeting effluent specifications, including basic sediment and water, H₂S, salt, and oil-in-water content.

We support early recovery by:

- Processing and treating fluids, including heavy oil, emulsions, gas condensate, and water

- Stabilizing gas condensate to meet export or sales criteria

- Performing frac flowback and solids handling

Fluid preconditioning

Ensure your fluids meet plant acceptance criteria—efficiently and sustainably.

We combine advanced surface well test equipment, domain expertise, and tailored configurations to deliver a fit-for-purpose fluid preconditioning solution. Produced fluids are collected, separated, and treated to specification—enabling earlier production, reducing opex, and accelerating returns.

This solution is particularly effective for revitalizing mature wells, helping you overcome pressure challenges, production system constraints, and high backpressure.

Surface pressure boosting

Overcome flow limitations and enable early production—even from remote wells.

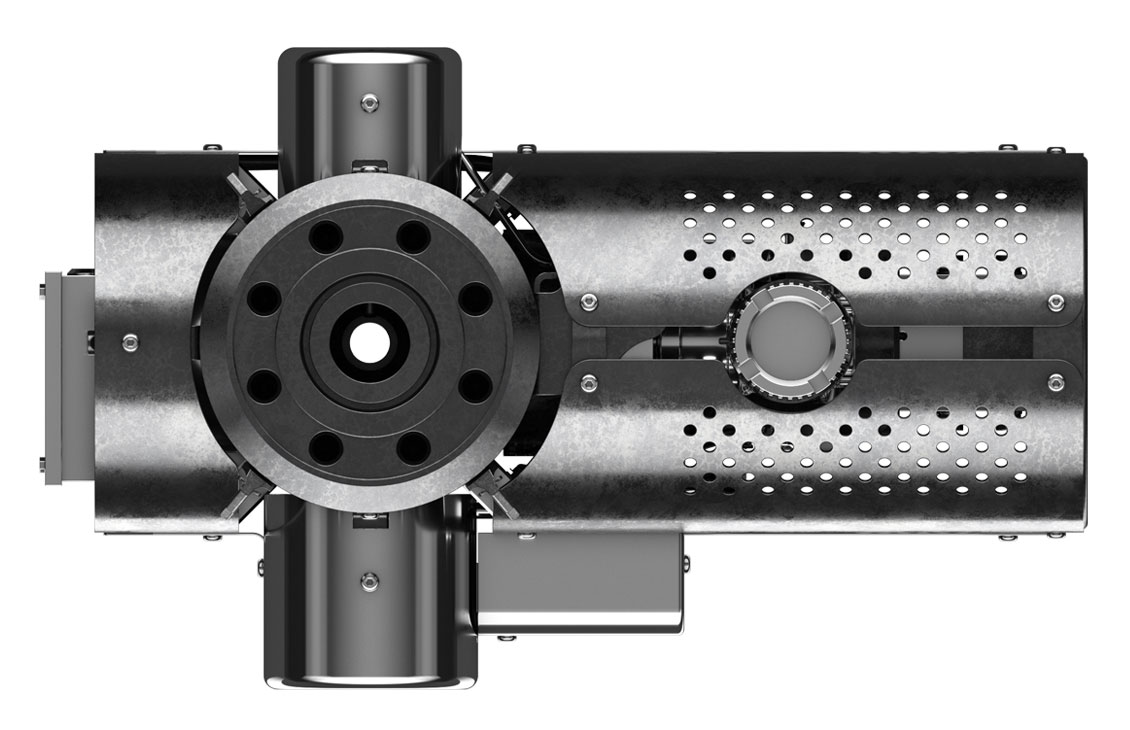

Our standard surface well test equipment includes multiphase pumps with high gas volume fraction (GVF) capability. These systems support well unloading and production boosting by enabling single- or multiphase effluent to be pumped directly into the production line.

Surface boosting solutions also support zero-flaring early production from wells located too far from existing infrastructure for natural flow—helping reduce emissions and accelerate time to first oil.

Gas monetization

Reducing flaring while increasing oil production is a dual objective central to the SLB decarbonization strategy. Our gas monetization solutions enable customers to capture flared gas and convert it into value—supporting both environmental goals and operational efficiency.

Production Express solutions play a key role in this transformation. They enable fit-for-purpose solutions such as gas-to-power, gas-to-LNG, and gas conditioning for local distribution. These applications help integrate flared gas into the existing domestic value chain or prepare it for export—reducing carbon intensity across operations.

By monetizing flared gas on site or through scalable infrastructure, we help our customers—and our own operations—advance toward lower-carbon production.

Debottlenecking

Unlock additional capacity without major infrastructure changes. Our debottlenecking solution helps you increase plant throughput by optimizing existing assets.

We assess your facility’s operating conditions by comparing current system parameters with original design specifications. Based on this analysis, we implement targeted improvements—ranging from system reconfiguration and advanced engineering to water separation and the addition of production trains. The result: increased capacity, improved uptime, and extended asset life.

Facility and pipeline commissioning and maintenance

We integrate surface well testing and production equipment with existing facilities to enhance operational performance. Our equipment is designed for transportability, connectability, and operability, and complies with international production codes and standards. This enables commissioning and maintenance activities to proceed as planned—minimizing delays and maximizing uptime.

We also support reliable and efficient fluid management during pipeline interventions. Our solutions enable safe fluid reception, diversion, and return disposal—critical during both active operations and decommissioning phases. During commissioning or maintenance, pipelines may contain large volumes of single- or multiphase hydrocarbons, as well as fluids such as CO₂, N₂, or fuel.

Our systems help you manage these complex fluid profiles with greater control and confidence.

Zero-Flaring Capabilities

All Production Express solutions have zero-flaring well test and cleanup capabilities to decarbonize your operations. Zero-flaring well test and cleanup is part of our Transition Technologies portfolio and eliminates the emissions that are normally related to flaring. This emission-reducing solution enables flare-free well testing and cleanup operations with an integrated approach using fit‑for‑purpose technologies and techniques.

Learn moreFeatured products

Let's optimize your production

Talk to a domain expert and discover how our rapid production response solutions can help you overcome temporary production challenges.