Innovative well testing solutions boost oil production by 12,000 bbl/d, Iraq

TotalEnergies faced significant challenges in the Ratawi Field, aiming to meet an oil production target of 60,000 bbl/d amid disconnected wells and difficult terrain. The SLB innovative deployment of temporary pipelines and well testing solutions enabled the connection of four wells, boosting production by 12,000 bbl/d and enabling TotalEnergies to meet its production target on schedule and within time and budget. This project exemplifies overcoming operational hurdles with rapid, reliable, and efficient solutions.

TotalEnergies aimed to meet a production target of 60,000 bbl/d in Central Processing Facility 1 (CPF1) from the rapidly declining mature Ratawi Field. However, operational constraints—including disconnected wells, and lengthy approval processes for permanent infrastructure—posed significant challenges, especially for the high depletion rate of Ratawi field. Previous attempts to accelerate production were stalled due to a lack of certified infrastructure and long lead times for unexploded ordnance (UXO) clearance and material procurement. SLB maintained close contact with TotalEnergies to understand these unique challenges and collaborated to propose a rapid, temporary solution to connect wells and bring them back online without compromising safety or efficiency.

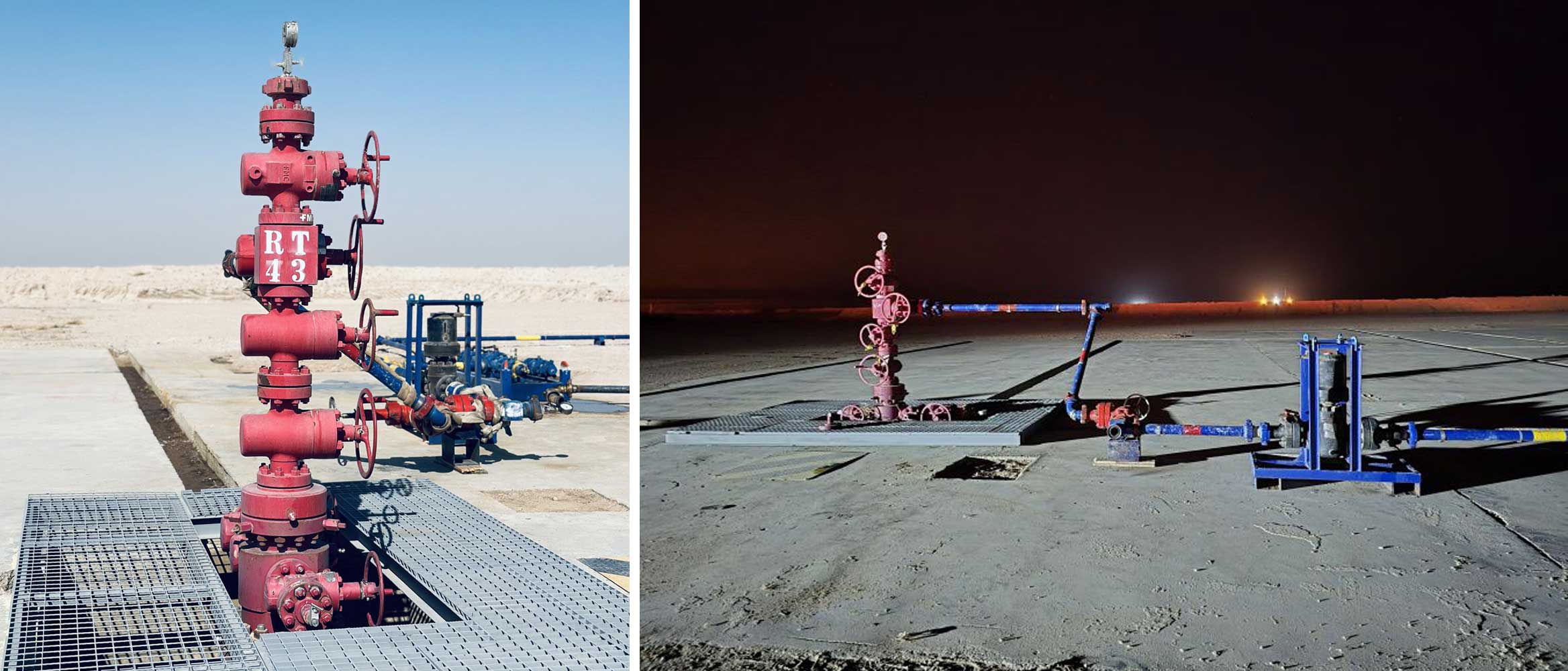

SLB addressed the challenges TotalEnergies faced by deploying temporary pipelines and well testing solutions. The temporary pipeline system utilized prepositioned equipment and pipes from local inventory, minimizing deployment time and ensuring rapid assembly with high-pressure ratings suitable for well production conditions. Well testing solutions provided customized flow assurance calculations and real-time production monitoring capabilities. Deployment and connection services enabled quick wellhead-to-CPF connections for four wells (RT-32, RT-41, RT-29, and RT-43), achieving a production increase of 12,000 bbl/d and meeting the TotalEnergies production target of CPF1.

The project strengthened the partnership between SLB and TotalEnergies, securing contract renewals and establishing SLB as a preferred partner in Iraq. Key learnings demonstrated how temporary infrastructure can effectively bridge operational gaps in mature and challenging fields, setting a precedent for future projects.

Other company, product, and service names are the properties of their respective owners.