Carbon storage regulatory permitting

Regulatory permitting for Class VI or CO₂ injection wells

Regulatory compliance is required to play

Carbon storage developers face numerous milestones as they plan, develop, and operate CO2 sequestration projects. One of the early and most critical steps is obtaining the necessary site permits. These regulations are designed to safeguard community health, protect underground drinking water sources, and minimize environmental risks throughout the project life cycle. They cover key elements such as site characterization, CCS well design and construction, well operations, CO2 injection monitoring, CCS well abandonment plans, and emergency response plans. These permits include Class VI in the United States and similarly modeled regulations for CO2 injection wells in other countries such as Norway, Denmark, the Netherlands, the United Kingdom, and others.

At SLB, we bring extensive expertise, having contributed to over 150 CCS projects globally and supported the permitting process for numerous sites worldwide. We can help you develop the necessary analysis and documentation by leveraging our Sequestri™ carbon storage solution portfolio and tailoring it to either your local regulatory requirements or global best practices. Key documentation we can assist with includes:

- Carbon storage application narratives

- Emergency response plans for CO2 leakage or other

- Area of review and corrective action plans

- Well construction detailed plans

- MMV testing and monitoring plans

- Well plugging and abandonment plans

- Postinjection site care plans

- Stimulation programs

Learn more about how we can support you through every phase of your CCS project.

Site evaluation

At SLB, we use our industry-leading modeling and simulation digital technologies in multidisciplinary workflows to process well data, interpret geophysical data, build subsurface models, and simulate CO2 plume migration during injection and postinjection to determine the best sites for carbon sequestration. In addition, using cloud computing, we can run multiple ensembles to identify, reduce, and optimize risk management.

MMV and emergency response plans

Regardless of whether your carbon storage site is a depleted oil and gas reservoir or saline aquifer, clastic, sandstone, or basalt, we’ve built a process to help you design an MMV plan that prioritizes and mitigates risks. And we’ll collaborate with you to build an emergency response plan that not only honors your organization’s governance and HSE standards but also aligns with regulatory best practices.

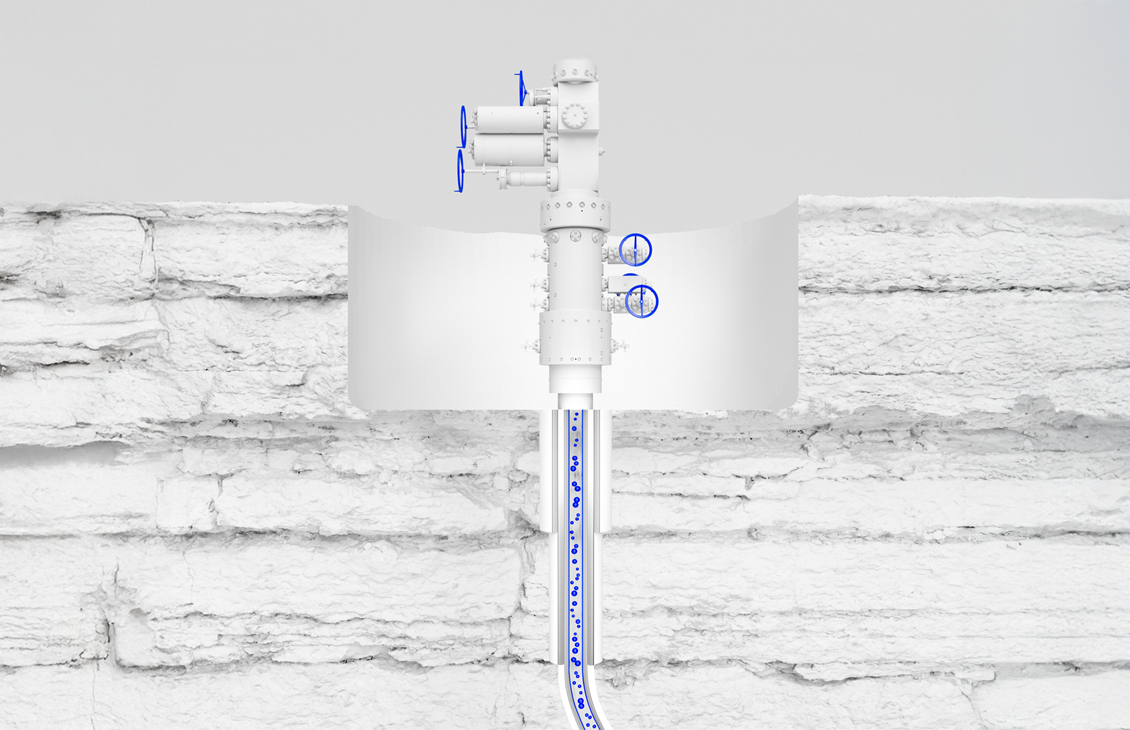

CCS injection well design and construction

For CCS well design and construction, we offer a portfolio of technologies specifically designed to withstand supercritical CO2 pressures, temperatures, and corrosion such as EverCRETE™ CO2 resistant cement system and Integrity™ CCS subsurface safety valve. We have also qualified many of our oil and gas technologies for CCS applications so you can feel confident that your carbon is securely sequestered.

CCS injection operations and MMV

Our digital solutions for MMV planning and operations were engineered to simplify the complexity of developing and managing carbon storage sites. By integrating data and workflows, we can help you build cost-effective and optimized measurements, monitoring, and verification plans that comply with your regulatory environment.

CCS injection well abandonment

At SLB, we’ve helped safely plug and abandon thousands if not tens of thousands of wells in oil and gas that have reached the end of their productive lives. With our CCS-specific engineered technologies and technologies qualified for CCS applications, we can help you safely plan and execute the abandonment of CO2 injection and monitoring wells.

Ensure the success of your carbon storage project with SLB

Navigating the complexities of carbon storage, including site evaluation, regulatory compliance, injection operations, and monitoring for long-term site stability, requires expertise. We’ll help you derisk and maximize carbon storage performance with our trusted experience and the Sequestri carbon storage solutions portfolio that enables compliance and delivers optimized project economics.

Contact usBe storage confident

Other carbon storage solutions

Carbon storage site evaluation

In-depth analysis to evaluate your carbon storage project

Carbon storage injection operations, measurements, monitoring, and verification

Cost-effective CO₂ injection planning and management

Carbon storage well design and construction

Designing and constructing CCS-specific wells to withstand the test of time

Carbon storage regulatory permitting

Regulatory permitting for Class VI or CO₂ injection wells