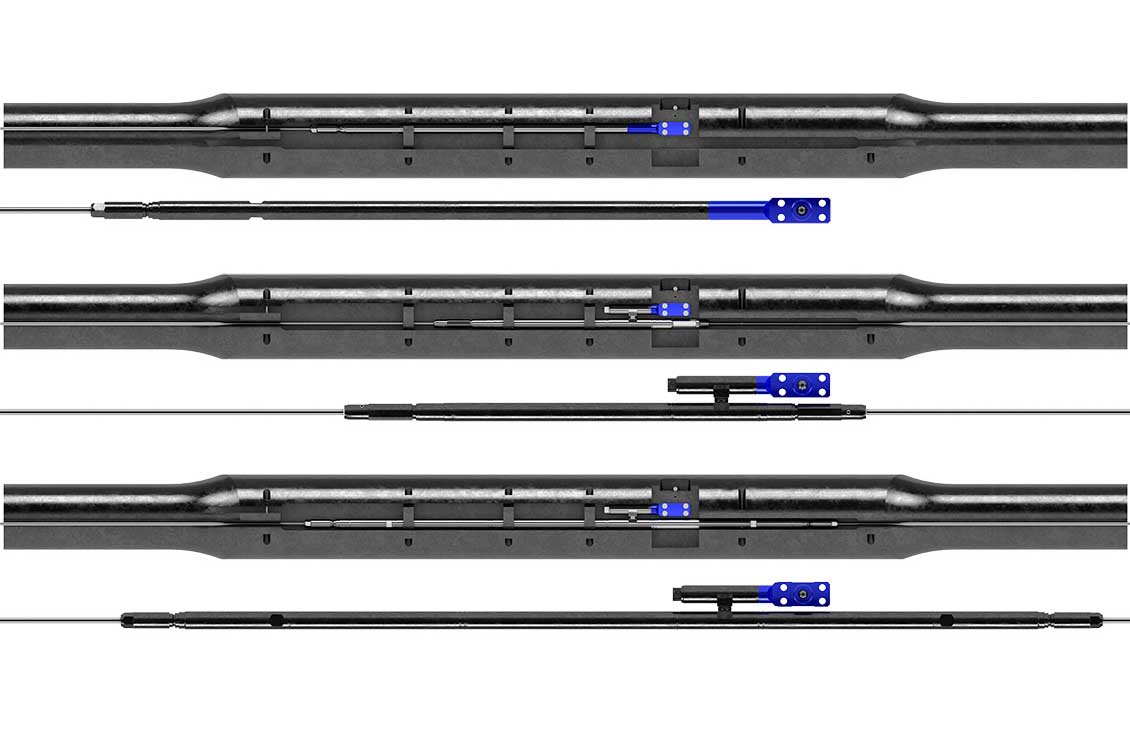

EverCRETE System Is Ideal in Any CO2 Environment

EverCRETE CO2-resistant cement system serves as a barrier for CO2 storage wells or high-CO2-producing formations

EverCRETE CO2-resistant cement system extends cement barrier lifetime in reservoirs containing CO2.