OnWave

Autonomous logging platform

Ultraefficient, low-risk formation evaluation deployed without wireline.

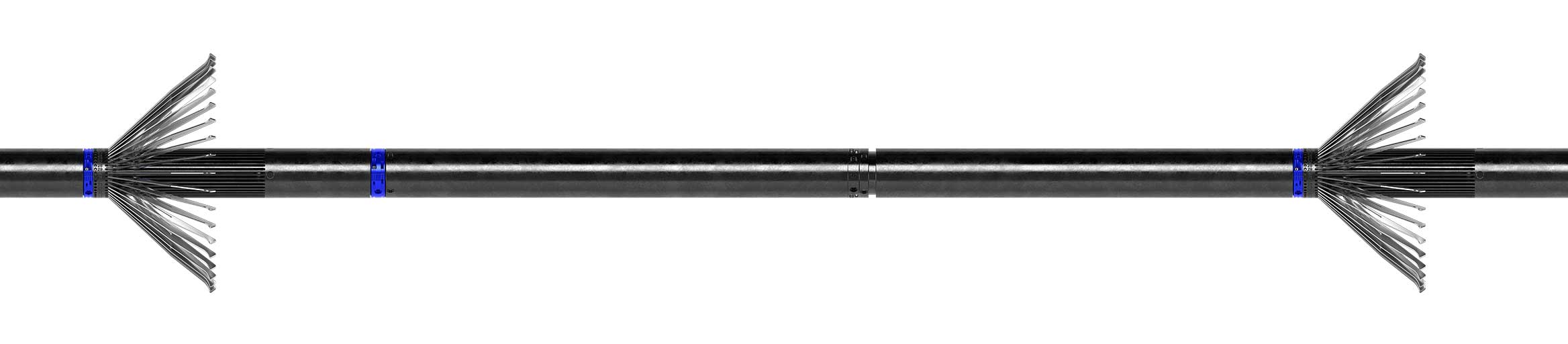

The high-resolution dual caliper accurately pinpoints various types of defects in downhole tubulars, completion components, and casings. This breakthrough capability is enabled by innovative engineering design that integrates an 80-finger arrangement in a 2 1/8-in-OD tool. This one-size tool covers a range of pipe sizes without compromising radial accuracy.

The tool can run in any well deviation and delivers real-time answers powered by a digital cloud platform that links the wellsite to your desktop, tablet, or laptop. With direct access to the most accurate information available, you have the best inputs to design the next intervention operation.

Rated up to 20,000 psi [138 MPa]

Rated up to 347 degF [175 degC]

Rated to NACE MR0175 for sour service

The high-resolution dual caliper deploys an array of hard-surfaced fingers that accurately measure the inner radii even in harsh downhole conditions. Eccentricity effects are minimized by the equal azimuthal spacing of the fingers and a special processing algorithm. For highly deviated wells, powerful motorized centralizers ensure effective centering. The caliper's multimodular architecture allows adapting the tool to different surface rig-up height constraints or downhole conditions by removing one of the 40-caliper modules if needed.

The caliper's data acquisition and processing are supported by a digital cloud, which visualizes information while logging is still underway at the wellsite. This allows reviewing early results across critical zones and deciding on the next operation. Advanced algorithms allow multiple end users to work on the data in parallel without each end user needing to upload or download data. The cloud platform also enables quick look answers for maximum penetration, burst pressure per joint, and minimum inner diameter. The tool can run in real-time or memory mode and can perform a range of corrosion or pipe defect diagnostic.

| High-Resolution Dual Caliper Specifications | ||||||

| Outputs |

Internal casing image from multiple internal radius measurements |

|||||

| Logging speed |

1,800 ft/h [549 m/h] |

|||||

| ID range |

2 5/8—10 in [66.675—254 mm] |

|||||

| Vertical resolution |

0.1 in |

|||||

| Inner radius resolution |

0.002 in |

|||||

| Inner radius accuracy |

0.02 in |

|||||

| Relative bearing accuracy |

5° |

|||||

| Borehole fluid limitation |

NACE compliant, sour rated |

|||||

| Pressure |

20,000 psi [138 MPa] |

|||||

| Temperature |

347 degF [175 degC] |

|||||

| Tool OD |

2.125 in [53.97 mm] |

|||||

| Length* |

8.6 ft [2.6 m] |

|||||

| Weight* |

89.17 lbm [40.5 kg] |

|||||

| Tension |

9,892 lbf [44,000 N] |

|||||

| Dogleg severity |

30°/100 ft |

|||||

All specifications are subject to change without notice.

* For one section of 40 calipers without active centralizers