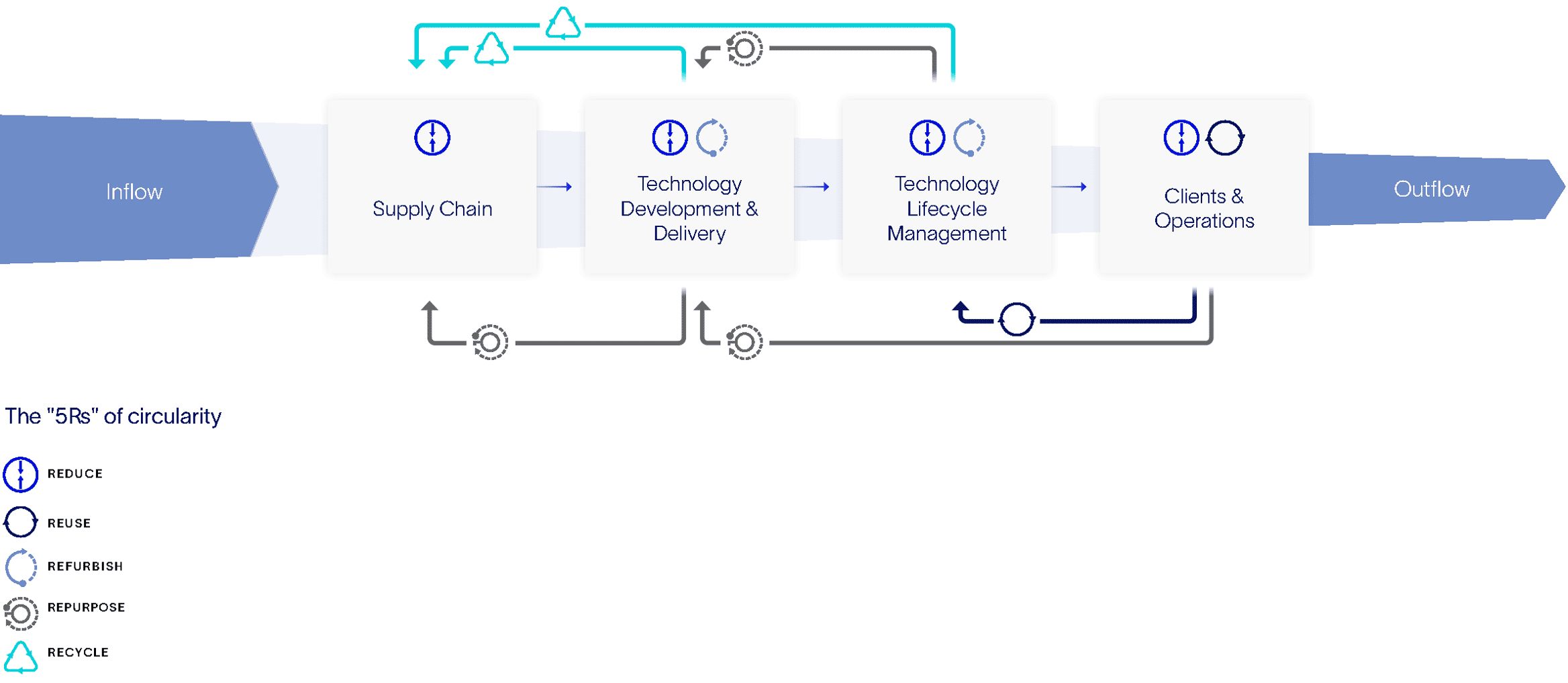

This function oversees the acquisition, maintenance, and enrichment of technology and equipment used in operations, focusing on optimizing reliability, sustainability, and performance to meet the evolving needs of our customers. The "5R” framework serves as a starting point to monitor and track improvements in our collective efforts, making circularity not only paramount for sustainability but also for our business impact. Aligning sustainability gains with profitability provides a greater incentive for innovation and expansion. Additionally, we’ve pursued innovation in sustainability challenges by leveraging data insights, machine learning, and video analytics, enhancing efficiency by reducing waste and enabling data-driven decisions for a more significant impact.