Carbon storage

Be storage confident with Sequestri carbon storage solutions

Simplify the complexity of developing and managing storage sites

Carbon sequestration projects are central to the global fight against climate change, providing a critical tool for reducing greenhouse gas emissions. But creating and managing a successful carbon sequestration project is no easy task. Effective carbon sequestration—or carbon storage—requires a thorough understanding of a site's capacity, injectivity, and containment, as well as its regulatory requirements, potential risks, costs to manage those risks, and more.

In this maturing industry, the tolerance for risk is low and the bar for investment high. At SLB, we recognize that minimizing risks and maximizing returns through efficiency and performance are essential to make projects bankable and reach final investment decisions (FID). Leveraging insights and best practices from over 150 CCS projects, our approach simplifies complexity by integrating data and workflows, managing risks, ensuring compliance, and optimizing injection operations.

Whether your project is in the early stages of development or has advanced to CO2 injection, SLB’s Sequestri™ carbon storage solutions offer a comprehensive portfolio engineered to simplify the development and management of carbon storage sites, ensuring you can proceed with confidence.

Simplify compliance

Utilize workflows, technologies, and best practices that simplify planning and execution to support regulatory requirements.

Optimize economics

Accelerate final investment decision using technologies that help you make the most cost-effective investment decisions.

Mitigate risks

Ensure injectivity, capacity, integrity, and containment of long-term CO2 sequestration.

Sequestri Portfolio: Proven Solutions for Carbon Storage Performance

SLB’s Sequestri portfolio offers a robust suite of proven, ready-to-deploy technologies engineered and qualified specifically for carbon storage. Developed to support every stage of the carbon sequestration lifecycle, these solutions deliver the technical certainty and operational confidence needed to accelerate your CCS and CCUS projects. Our technology ecosystem integrates digital and hardware innovations to streamline operations and optimize outcomes across your CCS value chain.

Whether you're an international oil company, national operator, or a pure-play carbon storage developer, Sequestri empowers you to screen, develop, and manage carbon storage sites with precision—ensuring long-term performance and regulatory compliance. Explore Sequestri solutions in the following areas:

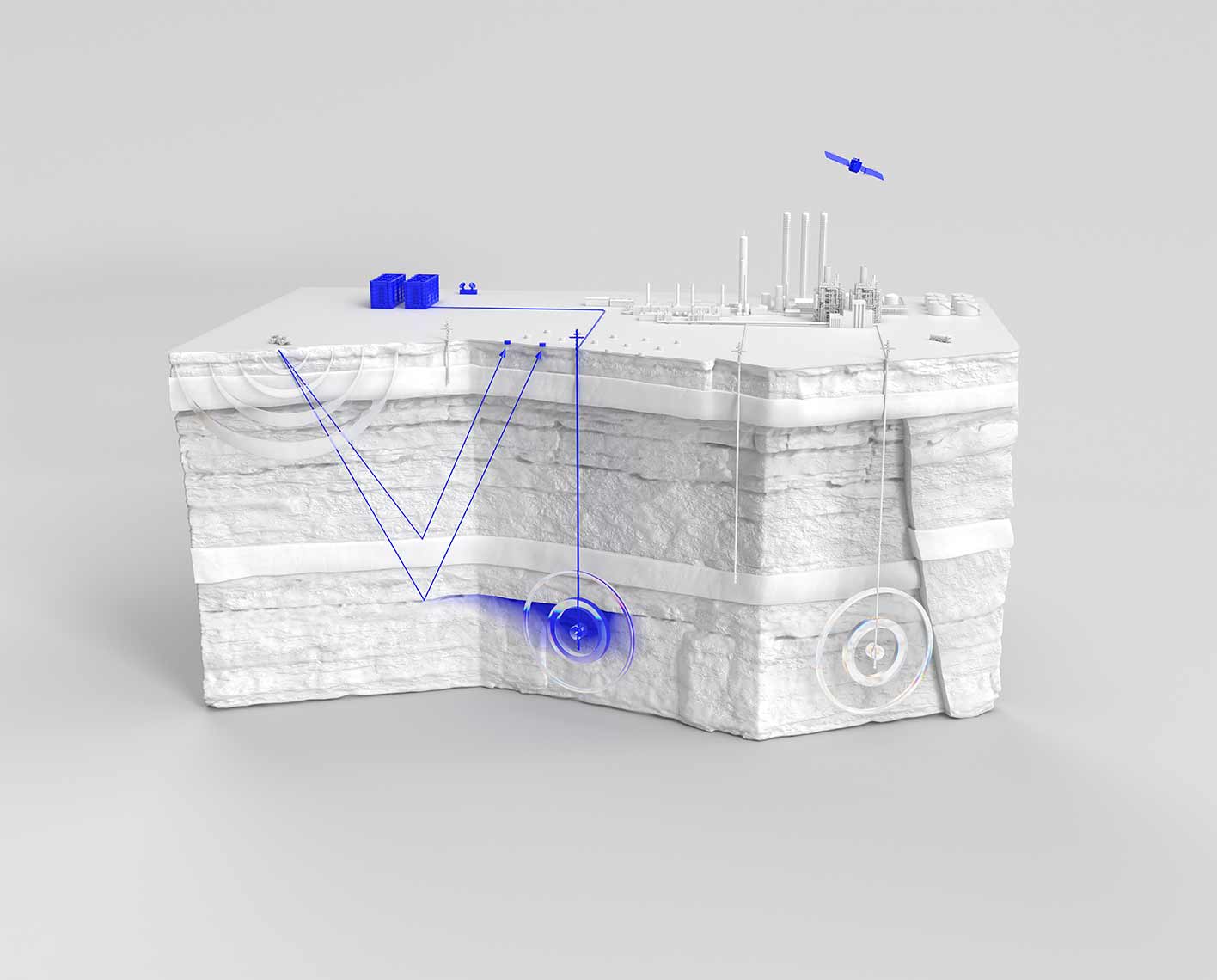

Site evaluation

From screening and ranking potential storage sites for capacity, containment and injectivity, to assessing existing wells for risk, to modeling and simulating the impacts of CO2 injection, a detailed evaluation of your potential carbon storage site is crucial to assessing its technical and economic viability. Our comprehensive portfolio of carbon storage technologies and workflows can help you prepare for FID.

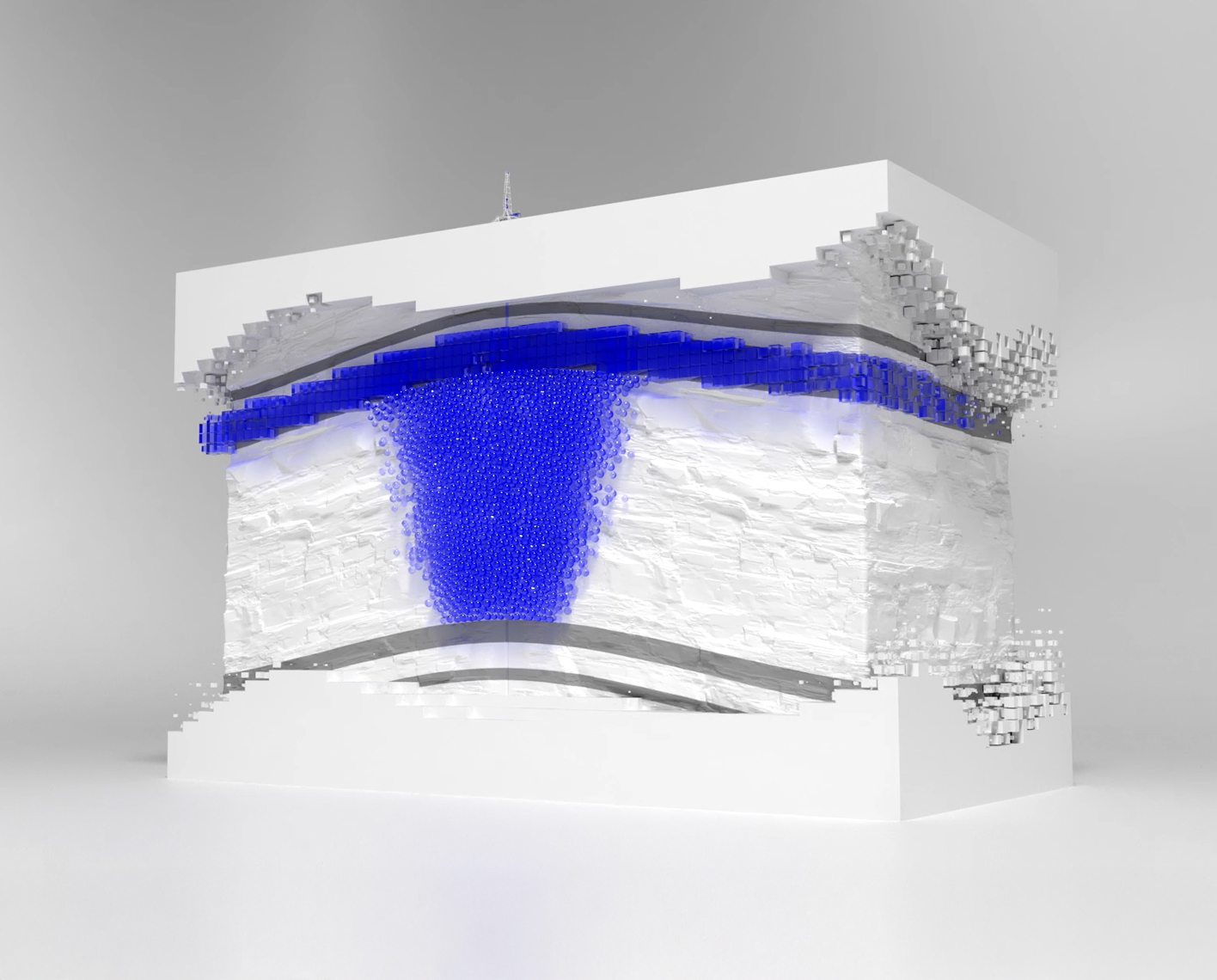

CO₂ injection operations, measurements, monitoring, and verification

Once you’ve selected a site, the next step is to prepare a measurements, monitoring, and verification (MMV) plan to manage risk, comply with regulations, and estimate the costs associated with the MMV plan. These costs will include site-specific measurement equipment, monitoring and analysis, IT and data management, and ongoing injection operations. The good news? With a robust MMV plan, you can minimize risks and optimize operations.

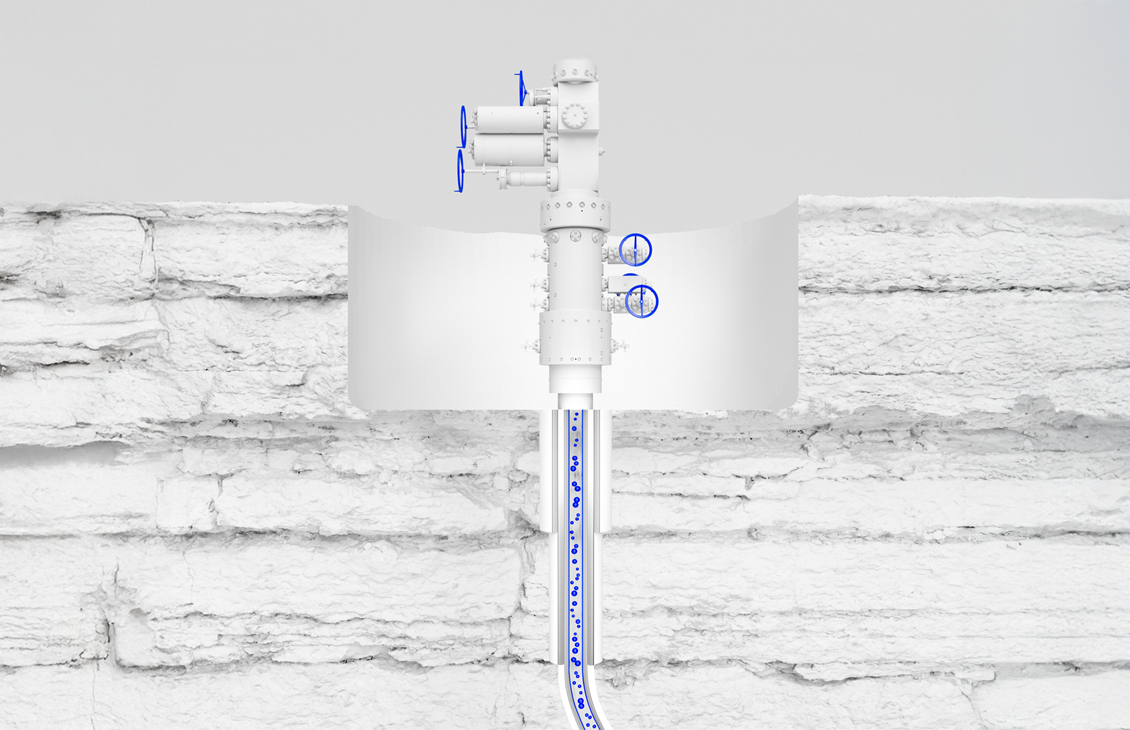

CCS well design and construction

Carbon storage or CO2 injection wells are unlike other wells. They must be designed to handle the injection of CO2 in a supercritical state and retain their stability and integrity decades after injection has concluded. With well construction equipment and materials that have been engineered to withstand the unique challenges of CO2, we’ve got you covered.

Regulatory permitting

With established engineering processes built on years of best practices from carbon storage projects, we leverage our knowledge to design MMV plans, architect injection wells, and comprehensively develop fields in areas with and without formal regulations. Let us put our broad and deep experience to work helping you navigate the complexity of injection well permitting.