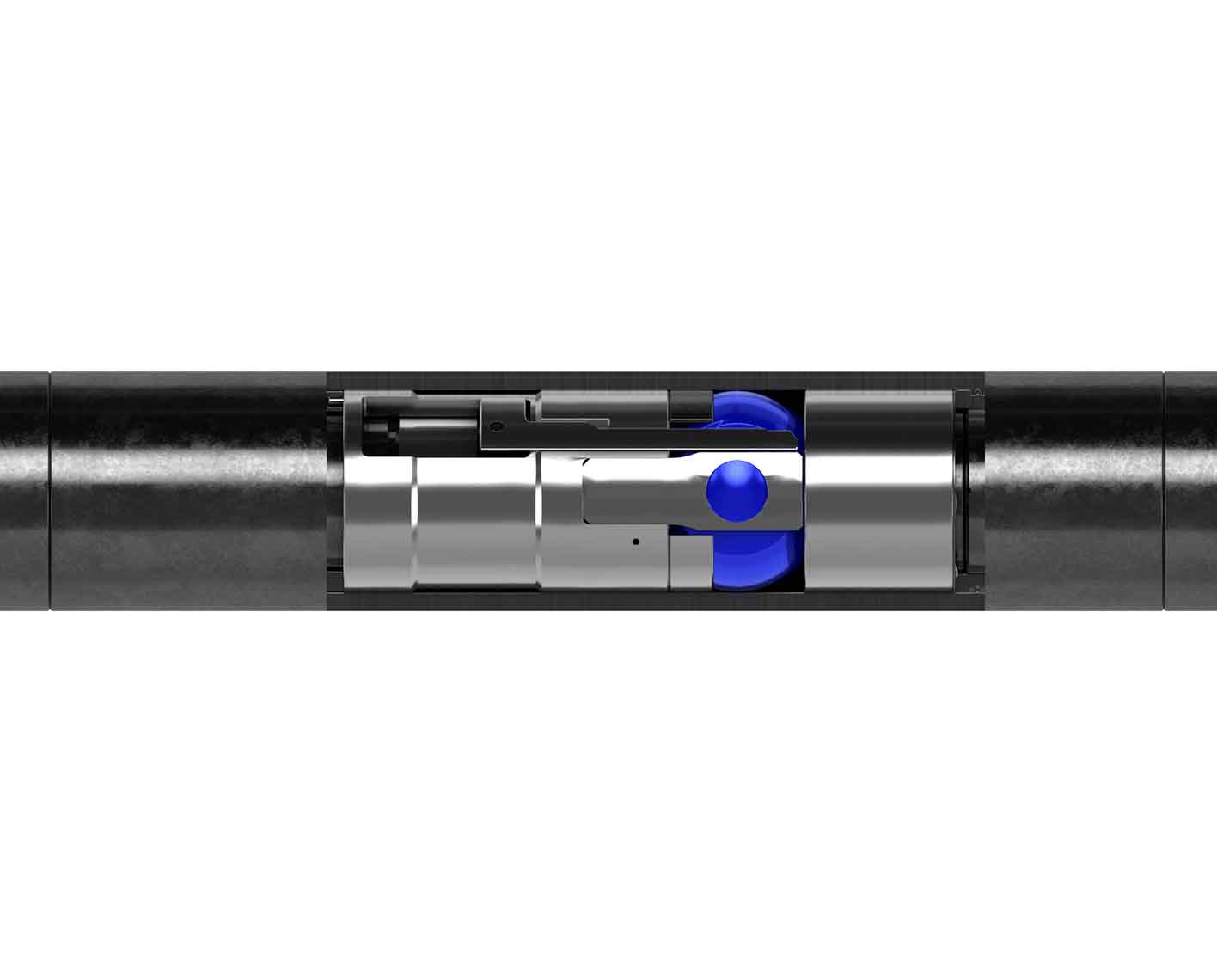

Downhole isolation barrier valves

Engineered for API 19V certified isolation, delivering secure barriers and faster completions across challenging environments

Complete control in any condition

Whether executing ESP workovers or batch drilling, SLB isolation valves provide certified performance across land, subsea, and HPHT wells—minimizing fluid loss, reducing flat time, and protecting formation integrity.

- Compatible with intelligent completions and multizone architectures

- Available in mechanical, hydraulic, and dual-trigger designs

- Validated to API 19V and ISO 28781 standards

Our Portfolio

API 19V and ISO 28781 Certifications

ISO 28781 and API Spec 19V are international standards that prescribe the requirements for subsurface barrier valves and related equipment for use in the petroleum and natural gas industries. Subsurface barrier valves provide a means of isolating the formation or creating a barrier in the tubular to facilitate the performance of well operations before production or injection starts. Barrier valves are also available for the postproduction or postinjection phase.

The standards define

- functional characteristics

- product material requirements

- quality control, defined by quality grades Q1 and Q2

- design criteria

- design validation, defined by qualification levels V1, V2, and V3

- design changes

- documentation requirements—operations manuals and product identification.

| Validation Grade | Test Medium | Flow Rate At | ||

|---|---|---|---|---|

| Validation Grade |

Test Medium |

Flow Rate At 200 psi Across Barrier | Flow Rate At 50% Rating | Flow Rate At 100% Rating |

| Validation Grade V1 | Test Medium Liquid | Flow Rate At 10 mL/min | Flow Rate At 5 mL/min | Flow Rate At 5 mL/min |

| Validation Grade V1 | Test Medium Gas | Flow Rate At 1 ft3/min | Flow Rate At 0.5 ft3/min | Flow Rate At 0.5 ft3/min |

| Validation Grade V2 | Test Medium Liquid | Flow Rate At 30 mL/min | Flow Rate At 15 mL/min | Flow Rate At 15 mL/min |

| Validation Grade V2 | Test Medium Gas | Flow Rate At, Flow Rate At, Flow Rate At No requirement | ||

| Validation Grade V3 | Test Medium, Flow Rate At, Flow Rate At, Flow Rate At Supplier- or manufacturer-defined and successful field history of 20 similar valves | |||

| Barrier from Above | Barrier from Below | Barrier from Above and Below | |

|---|---|---|---|

| Preproduction and preinjection barrier valves | Barrier from Above Type A | Barrier from Below Type B | Barrier from Above and Below Type C |

| Postproduction and postinjection barrier valves | Barrier from Above Type AA | Barrier from Below Type BB | Barrier from Above and Below Type CC |

Frequently Asked Questions about SLB Isolation Valves

What certifications do SLB isolation valves meet?

SLB valves are certified to API 19V (V1-V3) and ISO 28781 standards for barrier integrity and operational safety.

What’s the difference between mechanical, hydraulic, and dual-trigger valves?

Mechanical valves use physical activation; hydraulic valves use pressure; dual-trigger offers redundancy with electronic + hydraulic options. All non-strictly mechanical valves also have a shifting profile for mechanical intervention.

Can SLB valves be used in long-term suspension wells?

Yes—SLB valves support months to years-long isolation for well suspension and reentry.