Geothermal drill bits

High-temperature endurance for drilling geothermal wells

Geothermal drilling demands a drill bit that endures downhole temperatures that can exceed 500 degF. Extreme heat and high pressures quickly degrade traditional roller cone bit bearing materials, causing seals to fail and lubricants to break down. For PDC bits, conventional cutting elements surrender to hard-impact rock or succumb to the high heat of performance drilling, causing cutters to chip or break. These deficiencies mean loss of bit durability that shortens interval runs and increases bit trips—all of which increase drilling costs.

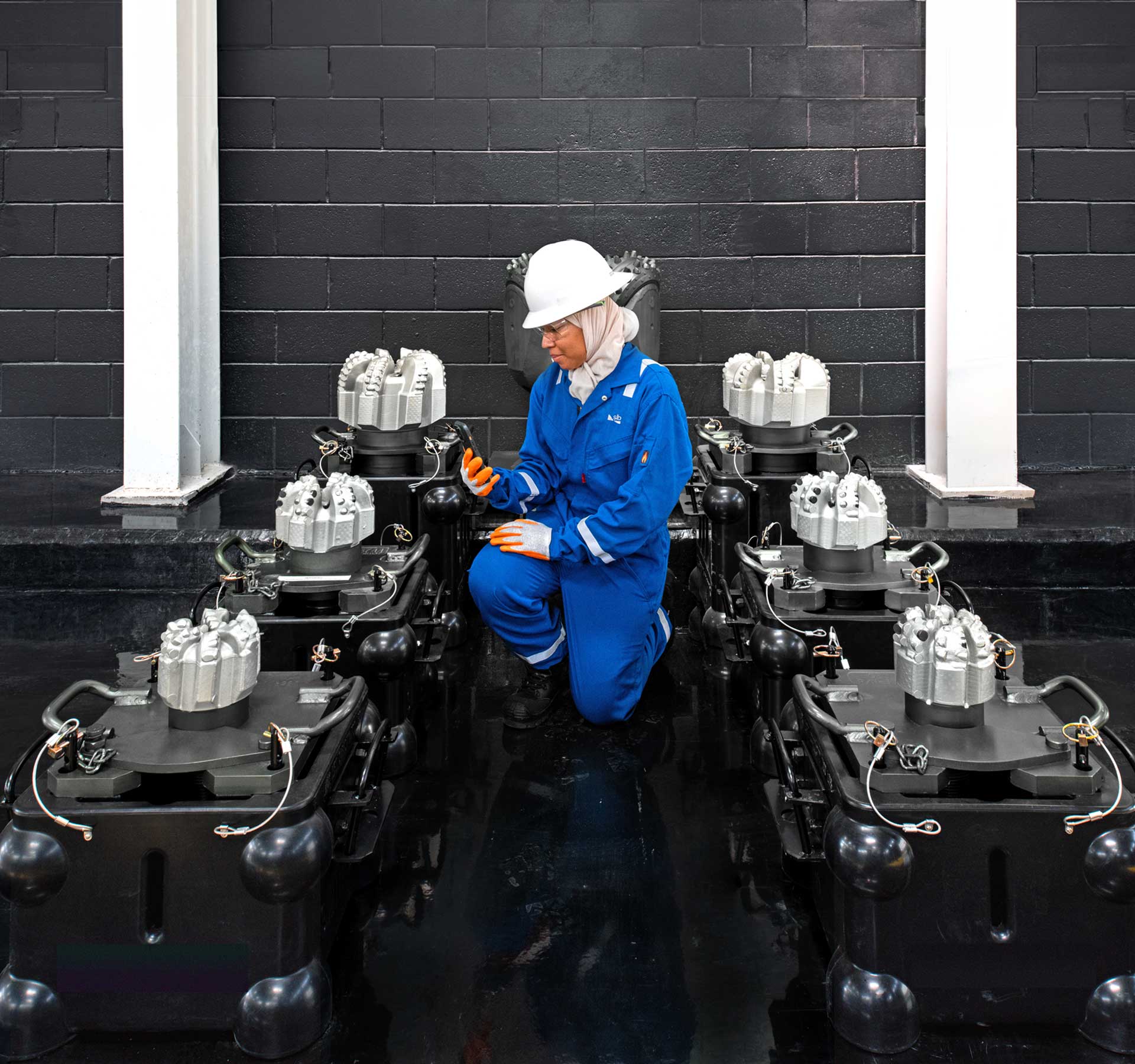

And because no single bit is right for every application, SLB has both roller cone and PDC drill bits designed, tested, and proved for the performance-drilling needs of geothermal wells.

Reshaping bit performance

What sets the SLB geothermal family of bits apart is that we begin developing bit designs based on where the bit meets the rock. And this approach is how we are reshaping PDC bit performance.

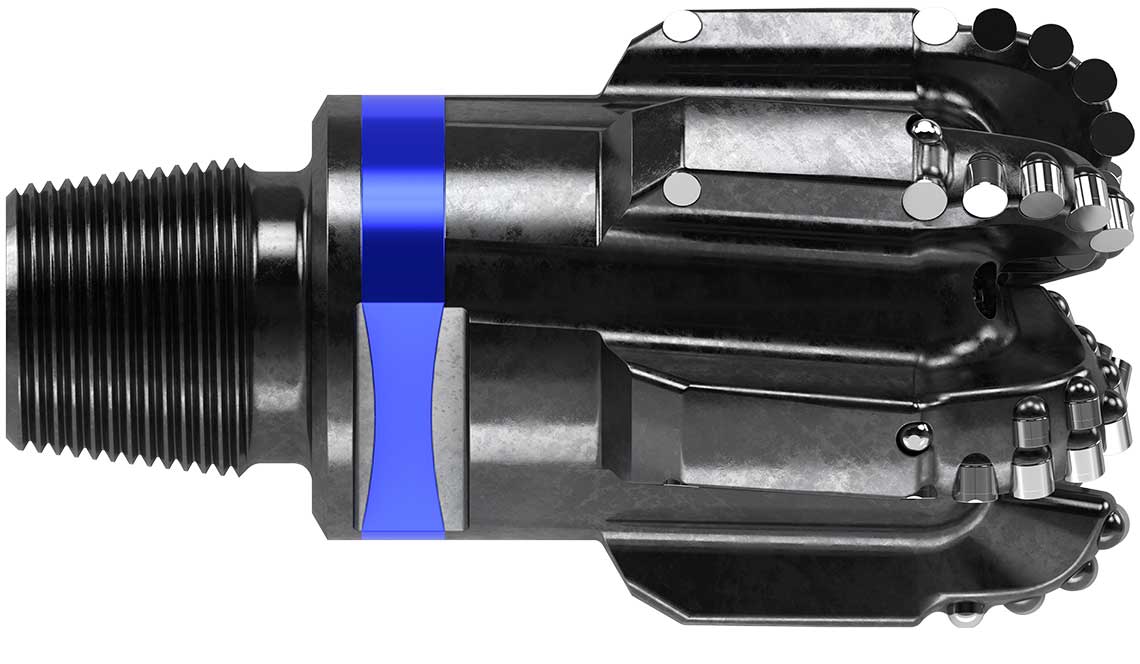

Our ThermoBlade™ thermal-resistant diamond element bit is the latest evolution of drill bits for high-temperature applications. It saves drilling time by reducing the need for costly bit trips because the bit integrates thermal-resistant diamond cutting elements that mitigate the effects of thermal degradation—cracking and chipping of the cutter surface—during geothermal well construction, increasing durability, extending bit life, and improving overall bit performance. Thermal stability has even been proved in conditions approaching 1,832 degF [1,000 degC].

Our StingBlade™ conical diamond element bit integrates the Stinger™ conical diamond element, which concentrates a higher point load on the rock—literally putting performance on point. The Stinger element has a thicker diamond table, and the conical shape is well-known for its ability to withstand extreme compressive loads experienced while drilling high-impact formations that wreck conventional cutters. StingBlade bits provide a 55% increase in footage with a 30% increase in rate of penetration, enabling significant reductions in bit runs and increases in rig-time savings.

Heating up endurance

The contact-point approach for bit development is equally crucial to roller cone bits. In applications where roller cone bits drill hard and abrasive lithologies to access steam or hot rock in basement formations, they encounter temperatures in excess of 500 degF. That’s when standard 300-degF-rated elastomer seals and lubricating material degenerate, causing bearing failure and resulting in more bit runs.

When Xplorer Kaldera™ high-temperature seals are integrated into Xplorer™ premium roller cone drill bits, their proven durability in high-temperature applications withstands the conditions required for geothermal well construction—delivering longer seal life, lubricity, and load capacity at elevated temperatures. For example, in geothermal superheated steam applications where temperatures can reach 530 degF [277 degC], Xplorer Kaldera seals resulted in top performance.

3%–37%

33%

Featured products

Featured case studies

Our geothermal well construction solutions

Geothermal drill bits

High-temperature endurance for drilling geothermal wells

Geothermal directional drilling

Leveraging geothermal experience and technologies to drill geothermal wells consistently, faster, and more efficiently

Geothermal drilling fluids

Reduce drilling risk in challenging geothermal environments

Geothermal cementing systems

Resilience in extreme geothermal environments