Carbon storage site evaluation

In-depth analysis to evaluate your carbon storage project

Simplify selection of the most techno-economic carbon storage sites

Screening, ranking, and evaluating potential carbon storage sites is a complex process that requires both technical and nontechnical analysis. Digital solutions with integrated workflows tailored to the needs of carbon storage developers can improve efficiencies and accelerate the analysis required for final investment decision (FID).

Our Sequestri™ carbon storage solutions provide a comprehensive portfolio of digital technologies engineered to simplify the complexity of carbon storage development and management.

Underpinned by industry-leading technologies for subsurface modeling, simulation, and well engineering, Sequestri enables carbon storage developers to seamlessly integrate data and workflows, assess capacity, containment, and injectivity through CO2 behavior modeling and simulation, and identify, prioritize, and mitigate risks. This collective knowledge helps determine the most technically feasible and economically viable carbon sequestration sites, ensuring developers can proceed with confidence.

Screen and rank

Site screening is an essential first step in identifying the most suitable location for a carbon storage project. A thorough evaluation process involves integrating geological, environmental, economic, and infrastructure data to provide a comprehensive, multidisciplinary analysis of site viability. This approach offers early insights into critical factors such as storage capacity, injectivity, containment, long-term performance, and economic feasibility. By employing structured, data-driven screening and ranking, decision-makers can confidently assess project potential, prioritize resources for detailed characterization and engineering, reduce uncertainties, and streamline the path toward a successful carbon storage initiative.

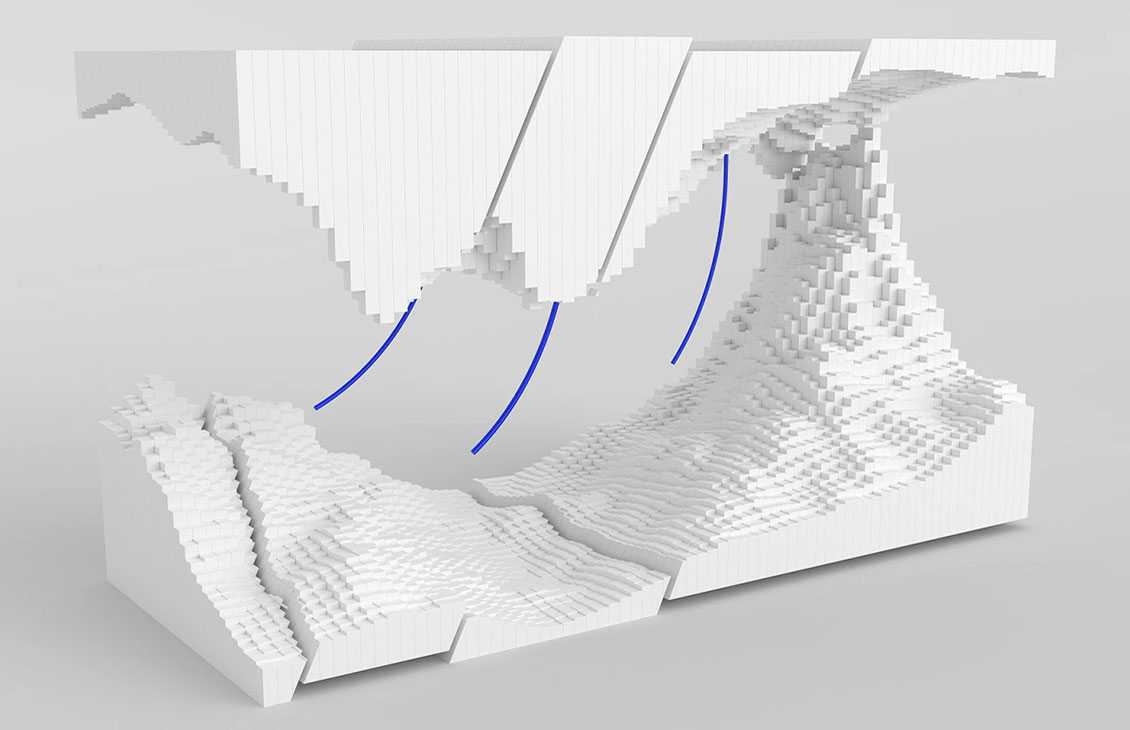

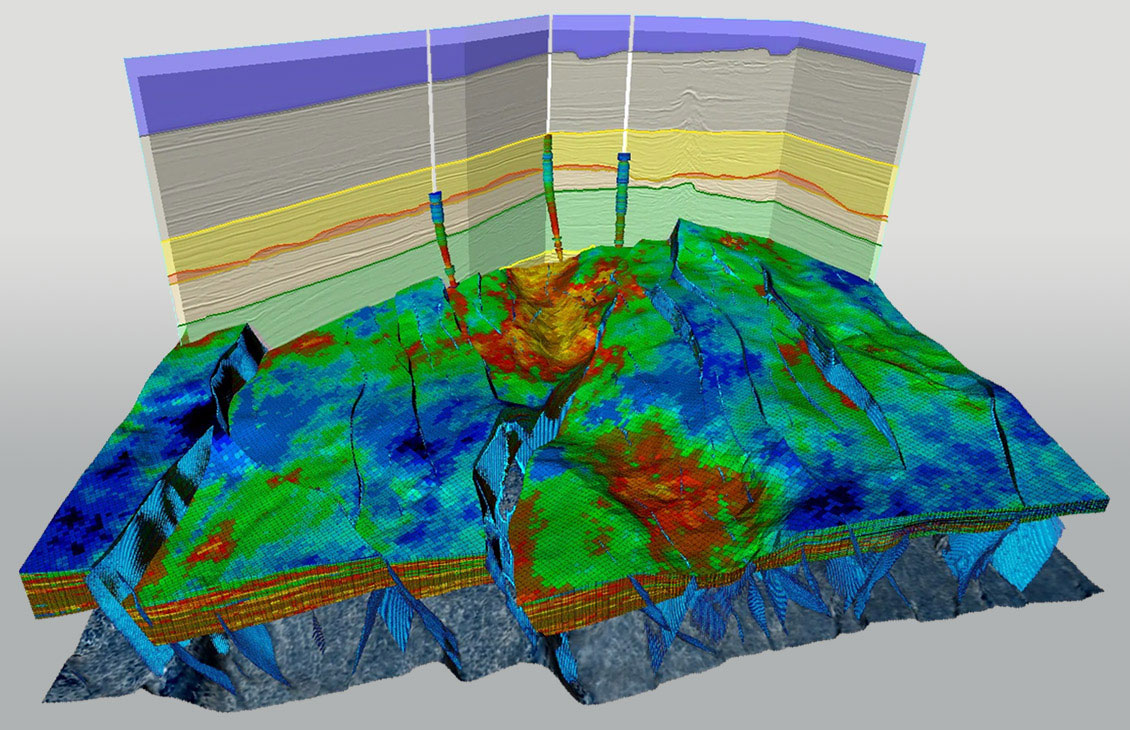

Model and simulate

Since reservoirs are expected to contain CO2 for extended durations, evaluating a storage site requires a thorough assessment of its long-term storage integrity. After building a reservoir model, reservoir engineers must also perform flow simulations to analyze various trapping mechanisms, assess the potential for CO2 migration, and examine the complex physical and chemical interactions between the injected CO2 and the reservoir. Additionally, these simulations help verify integrity of the caprock. To gain deeper insights into reservoir and structural integrity, additional studies may be conducted to integrate reservoir and geomechanical simulations.

Evaluation measurements

Optimizing carbon storage starts with understanding the reservoir. Grasping the concepts of capacity, injectivity, and containment is paramount, whether you're dealing with a depleted reservoir or a saline aquifer.

To comprehensively understand each of these, measurements from these workflows serve as a fundamental baseline for appraising the carbon storage site, as well as the development and execution of a carbon storage monitoring program. This ensures a well-informed and effective approach to carbon sequestration.

Assess risk quantitatively

Today, subsurface risk assessment methods typically rely on deterministic models and best-estimate scenarios, which often fail to capture the full range of uncertainties associated with subsurface storage, leaving developers exposed to unexpected capital expenses (capex) and operating expenses (opex). However, by incorporating probabilistic methods, sensitivity analysis, and scenario modeling to assess potential risk, we can reduce uncertainty, improve project predictability, strengthen financial planning, and build investor and regulatory confidence, all of which are crucial for successful carbon storage projects.

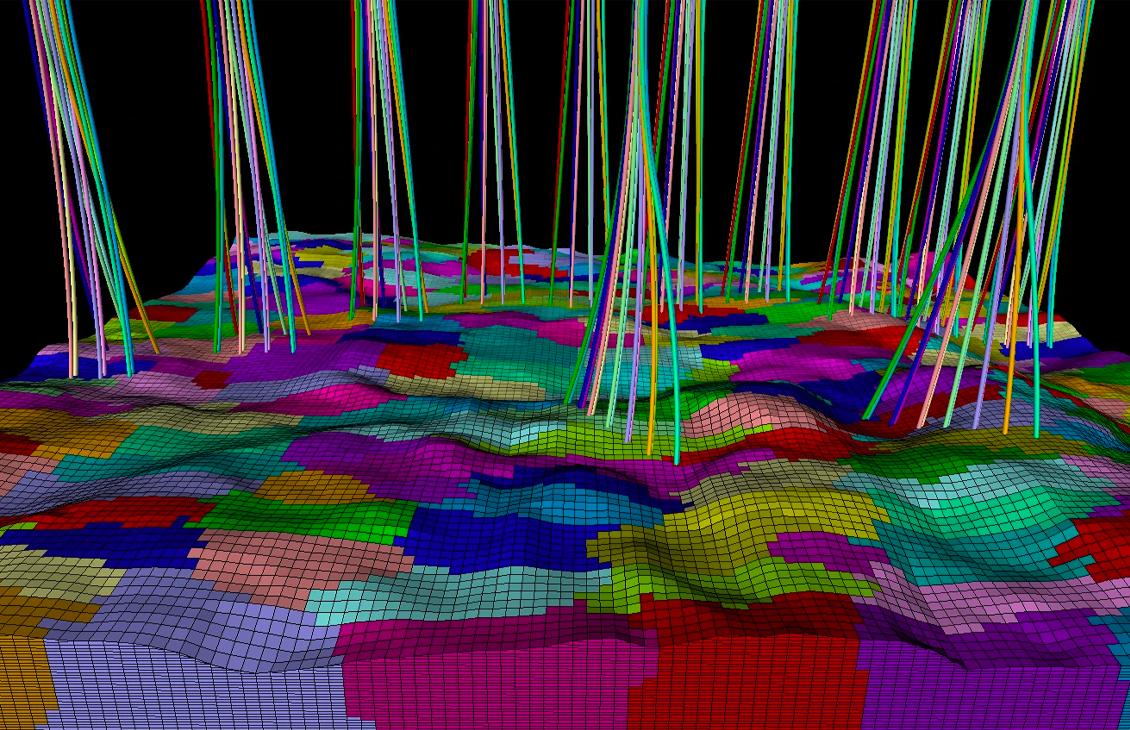

Assess well integrity

When screening, ranking, and evaluating potential sites for carbon storage, many technical and nontechnical factors must be considered in assessing a project's overall viability. One key technical criterion is the integrity of the wells within a potential site. Assessing well integrity is crucial when evaluating potential sites for carbon storage due to the risks associated with existing wells, especially in highly drilled areas.

Measurements, monitoring and verification planning

Ensuring the containment of CO2 in a storage site is crucial for minimizing environmental risks. To address this, regulatory frameworks have been established, requiring carbon storage developers to follow strict guidelines aimed at risk mitigation. A core aspect of regulatory compliance is the development and implementation of a thorough measurement, monitoring, and verification (MMV) plan.

For years, we have developed compliant, cost-effective, and site-specific MMV plans to support permitting, front-end engineering design (FEED), and final investment decision (FID). These plans provide the foundation for secure and responsible carbon storage.

Be storage confident

Other carbon storage solutions

Carbon storage site evaluation

In-depth analysis to evaluate your carbon storage project

Carbon storage injection operations, measurements, monitoring, and verification

Cost-effective CO₂ injection planning and management

Carbon storage well design and construction

Designing and constructing CCS-specific wells to withstand the test of time

Carbon storage regulatory permitting

Regulatory permitting for Class VI or CO₂ injection wells