Unique expertise, experience, and technology to ensure economic feasibility and long-term reliability.

Initial development plan for carbon sequestration: First milestone in Taiwan’s CCS journey

CPC Corporation, Taiwan, leveraged SLB’s decades of subsurface knowledge and global experience to take the first steps toward implementing ambitious carbon capture and sequestration (CCS) plans.

In pursuit of Taiwan’s objective to achieve net-zero CO2e emissions by 2050, CPC Corporation, Taiwan, aims to commence commercial CCS operations in 2030. The goal is to inject 5 million metric tons of CO2 annually into selected sites and gradually build up to 14 million metric tons per annum. Based on its long history with CPC Corporation, Taiwan, and extensive subsurface expertise, SLB was tasked with conducting a feasibility study for subsurface carbon storage. To do this, a preliminary field development plan was created, which included injection and monitoring well placement and design, risk management strategies, and a monitoring scheme.

SLB screened seven subbasins by integrating its in-depth knowledge of international CCS standards and guidelines; best practices and lessons learned from previous CCS projects; seismic, log, and core data; and regional geological information. A seaside storage site aquifer was selected for further evaluation.

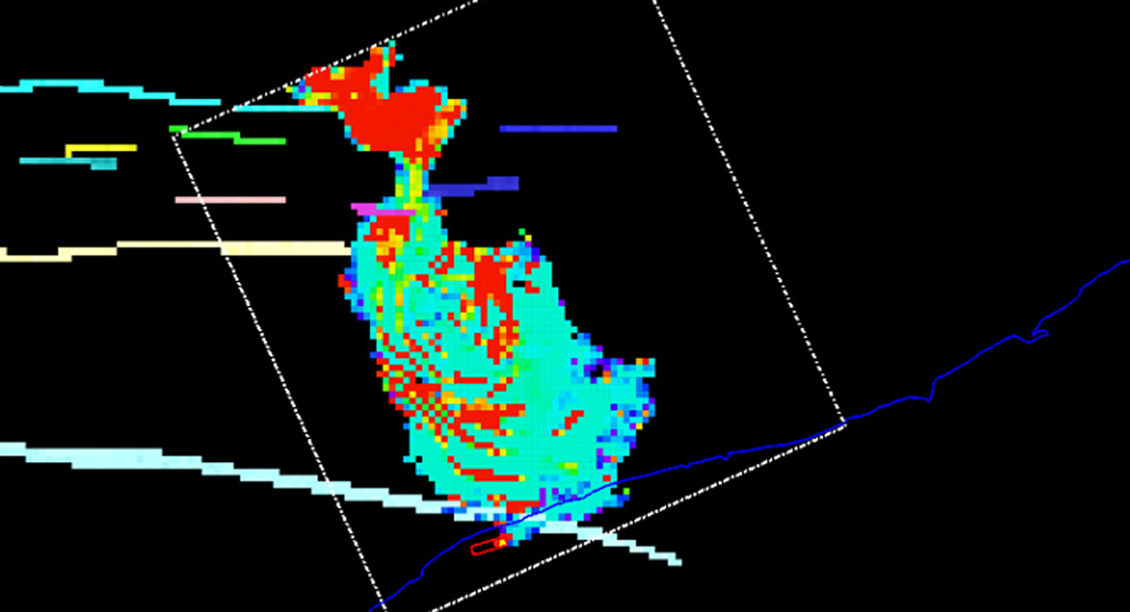

Eclipse™ industry-reference reservoir simulator was used to model the long-term dynamics of CO2 injection and storage in the aquifer. The focus was on investigating CO2 plume evolution and storage efficiency as a function of different trapping mechanisms. The numerical simulations enabled predicting the behavior of CO2 once it is injected into the subsurface, including its interaction with subsurface materials. The simulations were also used to inform project design, operations, and long-term containment.

A location was selected for the injection well, based on availability of land, reservoir quality, and distance from faults, and the injection and monitoring wells were designed. The horizontal injection well will have a 2,000-m [6,560-ft] lateral and is expected to enable an injection rate of 1 million metric tons of CO2 per annum. CCS injection wells face some unique challenges compared with standard injection wells, such as

- higher operational pressures and relatively low temperatures to inject CO2 in supercritical condition

- higher injection rates

- limited knowledge of geological sequestration sites, especially if the storage sites are saline aquifers

- longer operational time frame of up to 100 years

- exposure of the tubing, packer, and casing to corrosive carbonic acid

- long-term containment requirements.

Risk management and monitoring plans were drafted together with estimated costs. Equipped with a clear blueprint, including the timeline, key component requirements and costs, and an optimized operations plan to reduce risk and expenditure, CPC Corporation, Taiwan, is well-prepared to take the next steps toward realizing its carbon management ambitions.

Technical details

For more information, read ARMA 23-0175.